TL*-PET-121 DTF Pet a b transfer film transfer films

2024-08-19 14:01Understanding pET Films for Transfer Printing

Polyethylene Terephthalate (pET) films have become integral to various industrial applications, particularly in transfer printing. Known for their outstanding physical properties and versatility, pET films offer a reliable medium for high-quality image transfer onto different substrates. This article delves into the features, benefits, and applications of pET films in transfer printing.

What is pET Film?

pET film is a type of polyester film made from polyethylene terephthalate, a thermoplastic polymer resin of the polyester family. It is known for its strength, durability, and resistance to heat, moisture, and chemicals. These properties make pET films ideal for a wide range of applications, including packaging, labeling, and, notably, transfer printing.

Characteristics of pET Films

1. High Tensile Strength: pET films possess high tensile strength, making them resistant to tearing and stretching. This property ensures that the film maintains its integrity during the transfer printing process, resulting in crisp and accurate image transfers.

2. Thermal Stability: pET films can withstand high temperatures, a crucial characteristic for transfer printing processes that require heat. The thermal stability of pET films ensures that they do not deform or shrink under heat, which is essential for maintaining print quality.

3. Dimensional Stability: The low shrinkage factor of pET films ensures that they retain their dimensions during and after the printing process. This stability is crucial in applications where precise alignment is necessary.

4. Chemical Resistance: pET films are resistant to a wide range of chemicals, including oils, solvents, and acids. This resistance enhances the durability of the printed images, ensuring that they remain vibrant and clear even when exposed to harsh environments.

5. Optical Clarity: pET films are available in a variety of finishes, including clear, matte, and glossy. The optical clarity of clear pET films is particularly beneficial in transfer printing, allowing for accurate color representation and high-resolution prints.

Applications of pET Films in Transfer Printing

pET films are widely used in various transfer printing applications due to their excellent properties. Some of the most common applications include:

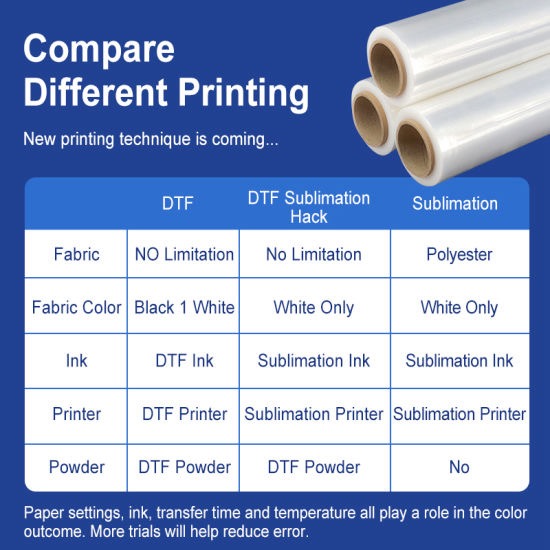

1. Textile Printing: In textile transfer printing, pET films are used as a carrier for dyes and inks that are transferred onto fabrics. The film’s thermal stability ensures that the image is transferred precisely without distortion, resulting in high-quality prints on garments, bags, and other textile products.

2. Industrial Labels and Decals: pET films are used to produce durable labels and decals that can withstand harsh conditions. The film's chemical and moisture resistance make it ideal for labels used in industrial settings, where exposure to chemicals and varying temperatures is common.

3. Packaging: In the packaging industry, pET films are used for transfer printing of logos, branding, and other decorative elements onto packaging materials. The film’s high tensile strength and dimensional stability ensure that the prints are of high quality and do not degrade during handling or storage.

4. Decorative Surface Printing: pET films are also used for transfer printing on decorative surfaces, such as furniture, electronic devices, and automotive interiors. The film’s ability to maintain image quality and resist environmental factors makes it ideal for these applications.

Advantages of Using pET Films in Transfer Printing

1. Cost-Effective: pET films are relatively affordable, making them a cost-effective option for large-scale printing applications. Their durability also reduces the need for frequent replacements, further lowering costs.

2. Environmental Impact: pET films are recyclable, which makes them a more environmentally friendly option compared to other materials. This recyclability aligns with the growing demand for sustainable printing practices.

3. Versatility: The adaptability of pET films to various finishes and thicknesses makes them suitable for a wide range of applications. Whether for textile printing or industrial labeling, pET films can be customized to meet specific requirements.

Conclusion

pET films have revolutionized the transfer printing industry by providing a reliable and versatile medium for high-quality image transfer. Their unique combination of strength, stability, and resistance to environmental factors makes them indispensable in various applications, from textiles to industrial labeling. As technology advances, the role of pET films in transfer printing is expected to grow, offering even more innovative solutions to meet the demands of modern printing techniques.