TL-PP-313 PP EVOH Film for packaging: universal barrier solution for industry, food, and pharmacy.

2024-08-22 12:04PP EVOH Film for packaging: universal barrier solution for industry, food, and pharmacy.

Polypropylene, PP, with ethylene vinyl alcohol film is a high-performance material used increasingly in various fields of packaging. Among the ideal films that ensure a very good barrier for sensitive products against moisture, oxygen, and other environmental factors is the PP EVOH film. This paper considers the properties, applications, and advantages of PP EVOH film in thermoforming and blister packing for the food, pharmaceutical, and other associated industries.

What is PP EVOH Film?

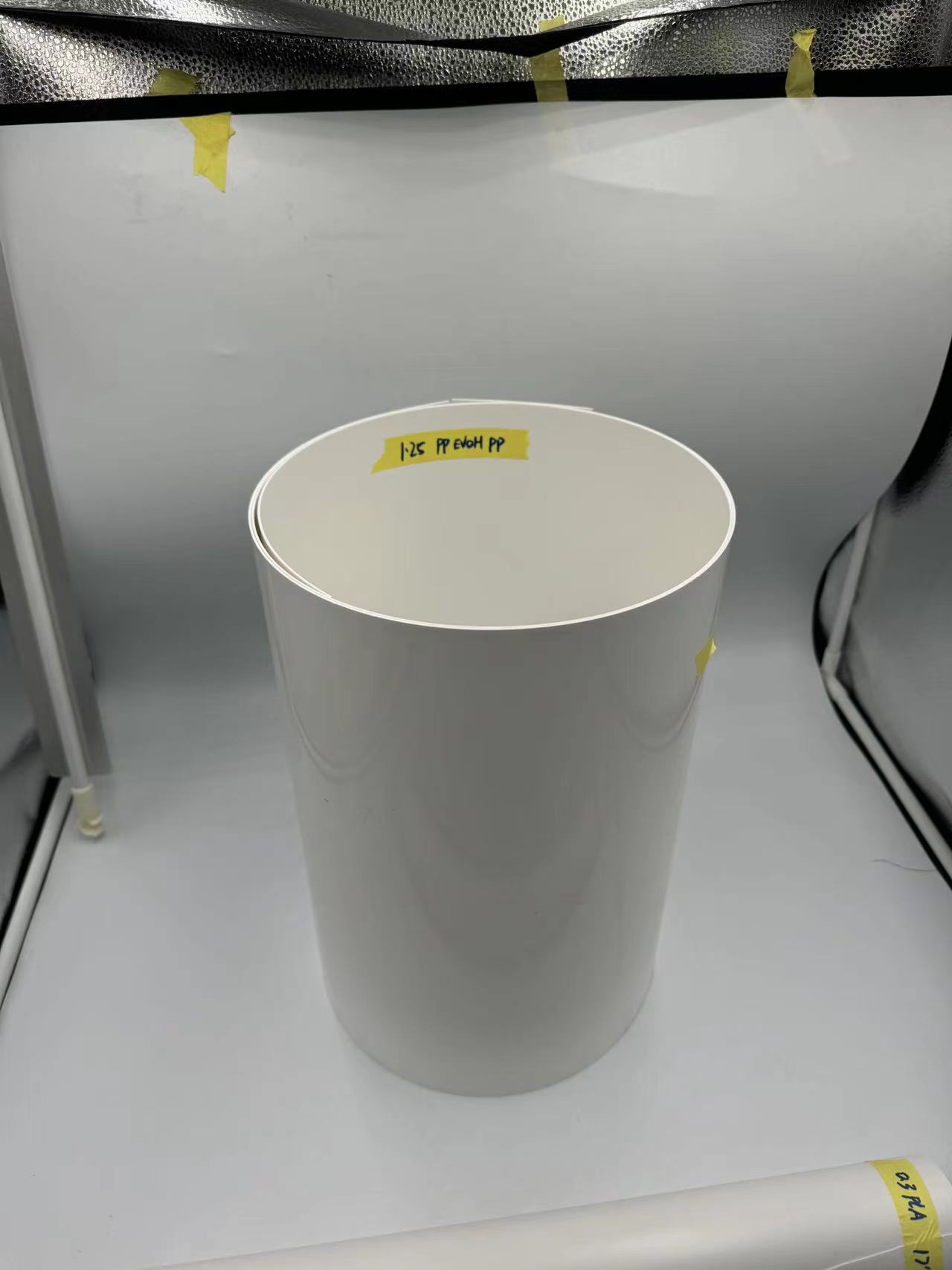

PP EVOH film refers to a multilayer structure where a layer of EVOH is coextruded with polypropylene. EVOH is a type of copolymer that shows exceptionally good barrier properties against gases, especially oxygen, from passing through the package. Combined with polypropylene, which contains added strength, flexibility, and heat resistance, the film is very suitable for various types of packaging.

Key Properties of PP EVOH Film

PP EVOH film finds its application in the packaging industry due to the following reasons:

1. High Barrier Performance: The barrier properties of the EVOH layer against gases, moisture, and odors help to extend the shelf life of perishable goods and sensitive products.

2. Thermoformability: PP EVOH film is easy to thermoform and can be molded into complex shapes to be used in a myriad of package designs, from trays to blister packs.

3. Durability: Because the combination of PP and EVOH produces a film that is not only strong but puncture- and tear-resistant, the integrity of the package through transportation and handling is guaranteed.

4. Transparency: PP EVOH film can be made very clear to see through, thus rendering good product visibility, which is critical in the consumer goods and retail packaging industries.

Applications of PP EVOH Film

1. Thermoforming Packaging

The thermoforming process involves heating the PP EVOH film and forming it into specific shapes to create custom packaging solutions. This process is used in many industries:

Food Industry: PP EVOH film is quite popular in the packing of perishable food products, such as meats, cheese, and meal-ready-to-eat. Its barrier properties keep food fresh and of good quality by avoiding oxygen and water entering the package, while its thermoformability makes it possible to create vacuum-sealed trays that hold the product secure.

- Pharmaceuticals: In the pharmaceutical industry, PP EVOH film is applied in the production of blister packs and trays to protect medications from moisture and oxygen. It materially ensures high barrier properties to secure the potency and safety of drugs during their lifetime.

2. Blister Packaging

One of the most used forms for coating a product with a transparent protective covering is blister packaging, and PP EVOH film finds quite a lot of use in this sector owing to its properties regarding strength and barrier performance.

- Food Products: In the food industry, PP EVOH film is used for blister packing snack foods, condiments, and fresh foods in small portions. It works well in these applications since it retains the protective barrier against gases and extends shelf life.

3. Industrial Applications

Besides food and pharmaceutical industries, PP EVOH film finds its major use in various industrial applications where protection from environmental elements is necessary:

Chemical Packaging: PP EVOH film is ideal for packaging oxygen- or moisture-sensitive chemical products because it does not allow contamination, thus retaining the integrity of the chemicals during storage and transport.

- Electronics: The electronics industry uses PP EVOH film in the packaging of sensitive components that require protection from moisture and oxidation. The film prevents degrading of these components, ensuring they can function and are safe during storage before their eventual use.

Benefits of Using PP EVOH Film in Packaging

Extended Shelf Life: Because of its high barrier properties, the PP EVOH film significantly helps to extend shelf life for perishable and sensitive products by very effectively keeping out oxygen, moisture, and other environmental factors.

Versatility: PP EVOH film offers a broad range of packaging applications—from thermoformed trays to blister packs.

Product Integrity: Strength and durability of the film guarantee the integrity of the package, therefore reliably protecting products during shipment and handling.

Sustainability: Technological innovations continue to drive the possibility for producing PP EVOH films with a lower environmental impact. Options for recycling make it more sustainable compared to other materials.

Conclusion

PP EVOH film is the most important material in packaging industries, offering extremely excellent barrier protection and versatility across food, pharmaceutical, and industrial applications. Herein, durability, thermoformability, and high barrier performance uniquely position it for use in packaging solutions that require protection and presentation. With industries continuing to ask more from their packaging materials, PP EVOH film stays at the forefront with reliable and innovative solutions.