TL-PET-113 Printable heat sealing customized PET film

2024-08-09 16:17Use of PET Sheets in Food Packaging and Labelling

Over the past years, polyethylene terephthalate sheets have been getting increasing consumer and producer interest since the material is characterized by excellent toughness and high strength. At the same time, it has superior transparency as compared to other materials. Other major advantages are easy printing, recycling properties, and environment-friendly performance of PET sheets, which make them perfectly suitable in the current trend toward eco-friendly materials since they allow not to emit harmful gases when being burnt.

PET Sheets Key Features:

1. Gloss and Transparency: With a high level of transparency and surface gloss, the PET sheet will find applications in many areas of packaging where the contents are to be displayed, with the high sheen providing an even more striking presentation of packaged goods.

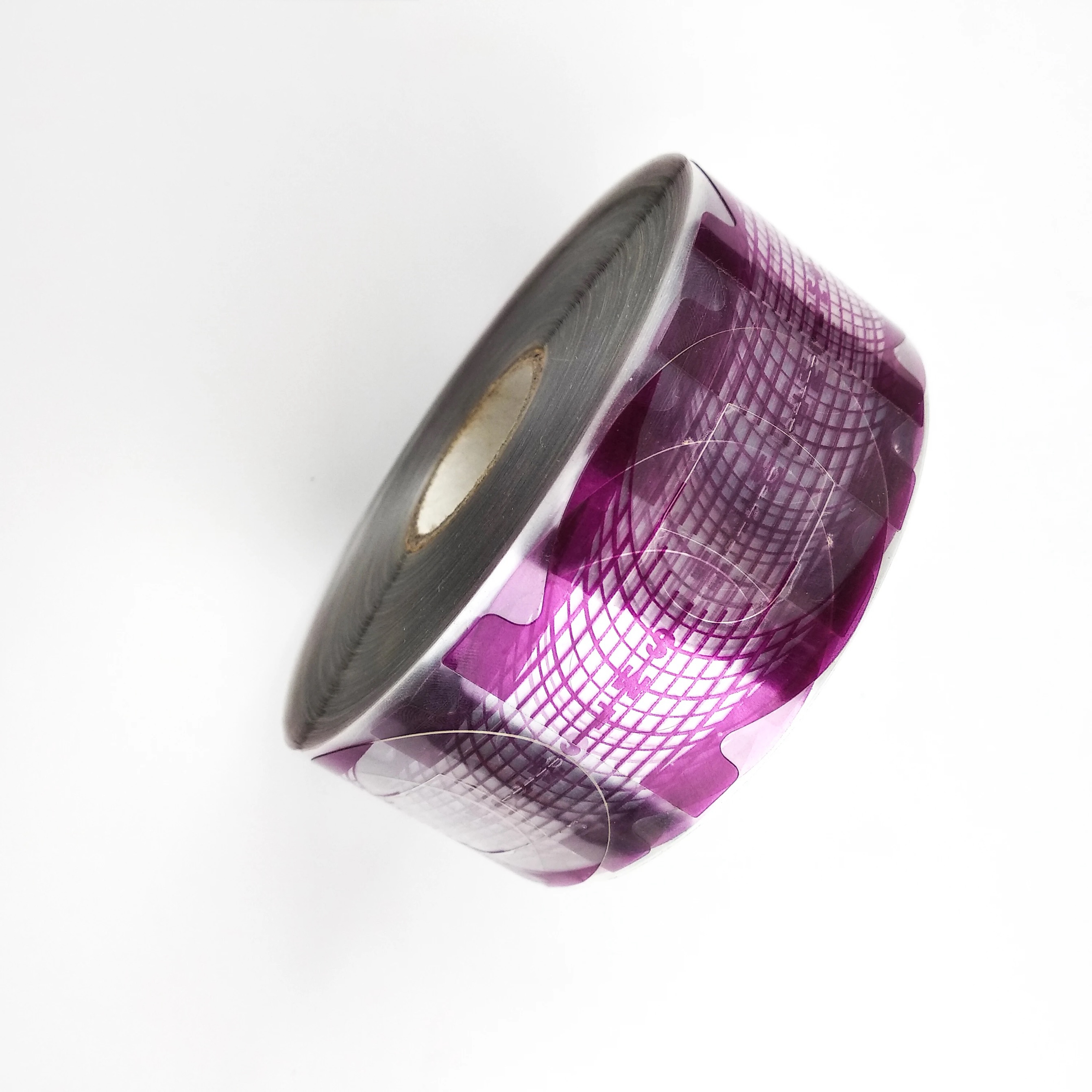

2. Surface Decoration: The PET sheets offer very good surface decoration. They can be directly printed without any kind of surface treatment. They are also readily embossable or metallizable—for example, by vacuum metal coating—and find applications in quality packaging and labelling.

3. Mechanical Strength: PET sheets show outstanding mechanical strength, thereby ascertaining that the package is strong and won't easily get spoiled while being transported and handled.

4. Barrier properties: PET provides excellent barrier protection against oxygen and water vapor, thus able to maintain freshness and other characteristics of food products.

5. Resistance to chemicals: Since it is resistant to a large number of different chemical substances, PET is widely applied for packaging goods containing active chemicals.

6. Safety and Hygiene: PET is non-toxic and passes very stringent hygiene standards, thus making it safe for food, pharmaceutical, and medical device packaging. Further, the PET packaging itself could be radiation-sterilized without impairing the safety and quality of the packaged goods.

7. Ecological Compatibility: PET sheets can be made very adaptable to meet all requirements regarding environmental protection. They can be easily and economically recycled. Moreover, while incinerating the PET waste, no hazardous substances are released, hence finding a place in the global scenarios of low impact on the environment. It also exhibits very good thermoforming performance, which is as good as conventional PVC sheets, hence can be used for vacuum forming in the production of high-performance packaging products.

Performance Parameters:

1. Density: 1.36g/cm³

2. Oxygen Permeability: 4–4.5 cm³·mm/ m²·24h·0.1MPa

3. Tensile Strength: 53 MPa in both the longitudinal and transverse directions.

4. Moisture Vapor Transmission Rate: 3 g·mm / (m²·24h)

5. Maximum Operating Temperature: Around 70°C

6. Elongation at Break: 250% in both the longitudinal and transverse directions.

7. Dimensional Stability: Changes in thermal dimensions are ≤ 5% in both directions.

8. Transparency: More than 90%

9. Compliance: GB 13113-91 hygiene standards.

Food Packaging Uses:

Given the excellent properties of PET, food packaging has always had huge demand for the material. Due to the light transmission of the material, the contents of the package are clearly visible to the customer; this aspect adds an advantage to the looks of the product on the store shelves. The excellent barrier properties help extend the shelf life of food products from oxygen and water, which are major variables of food spoilage.

Labeling Applications:

The excellent surface decorative properties make PET applied to labels. The material can be directly printed on to produce high-quality and durable labels that are resistant to wear. The metallization capability on PET sheets opens further options for the creation of premium, metallic labels that give a luxury feel to products.

Conclusion:

That is to say, with its impressive mechanical resistance, barrier properties, and environmental friendliness, PET is bound to satisfy the challenging demands of modern food packaging and labeling. Its adaptability and performance put it at the top of the list for a manufacturer seeking safety, appeal, and sustainability in the creation of packaging solutions.