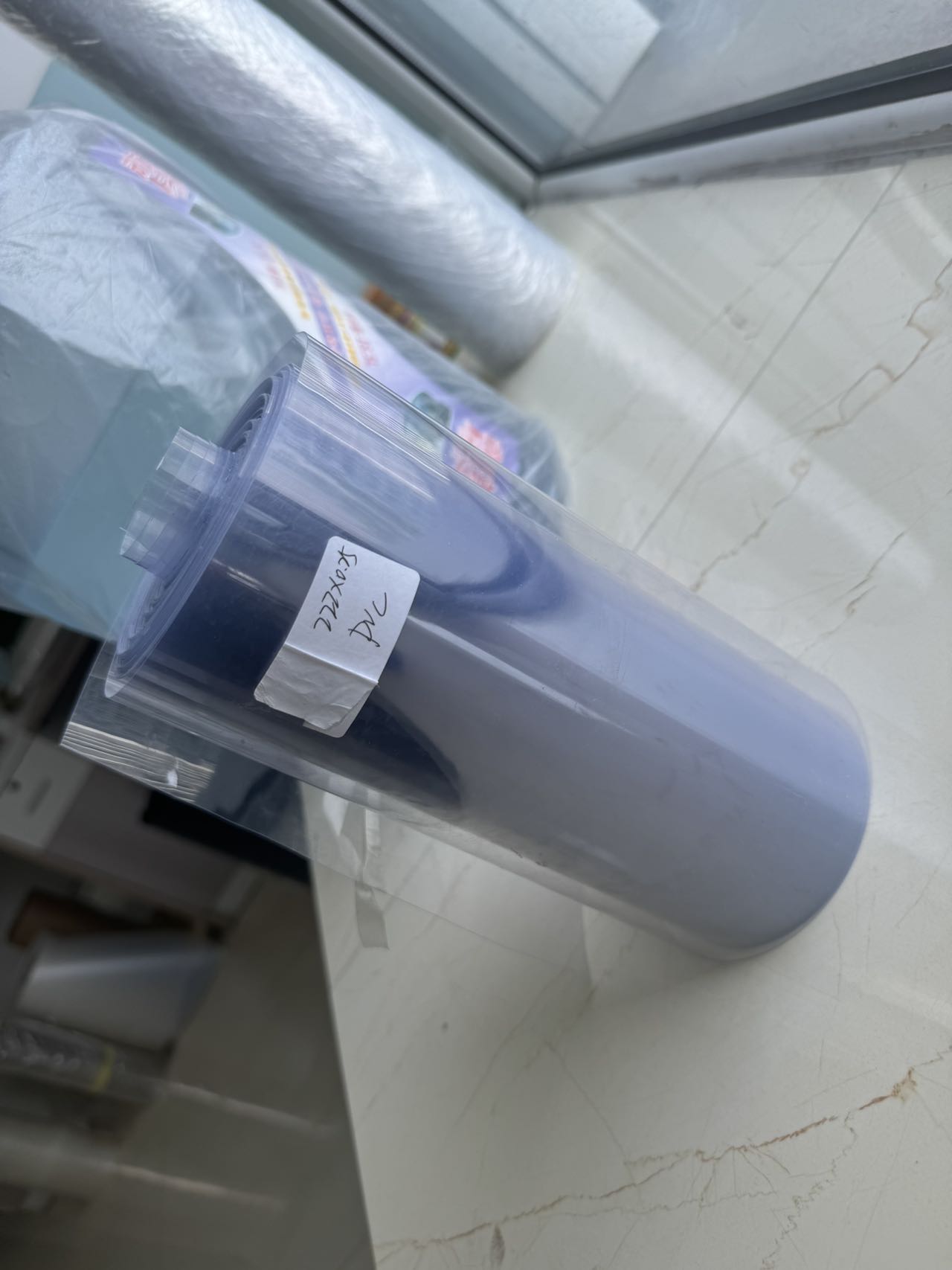

TL-PVC001pvc pharmaceutical packing

2024-07-24 16:15### Application of PVC in Medical Packaging

Polyvinyl chloride is the plastic with the highest output in the world, being one of the most applied worldwide. It has become an indispensable product in the packaging used in the medical field by the virtue of its adaptability, strength, and low cost. Here's a more in-depth look at the different applications of using PVC and why it's a go-to for many in the medical packaging field.

Polyvinyl chloride is the plastic with the highest output in the world, being one of the most applied worldwide. It has become an indispensable product in the packaging used in the medical field by the virtue of its adaptability, strength, and low cost. Here's a more in-depth look at the different applications of using PVC and why it's a go-to for many in the medical packaging field.

#### The Properties of PVC

Key outstanding features of PVC application in medicine are chemical resistance, high transparency, and flexibility. It can be easily sterilized, which is definitely important for the hygienic conditions of the medical premises. Besides, PVC can be formulated to be either rigid or flexible; therefore, it is very well adapted for a number of hundreds of packaging solutions.

#### Applications in Medical Packaging

1. **Blister Packs**: Yet another very common use of PVC in medical packaging is in the blister packs in which tablets and capsules are packaged. The material can allow the contents to be visible very well while also providing the rigidity needed from the durability in order to keep the medication safe from moisture and contamination.

2. **IV Bags**: IV bags are widely made of PVC. These bags need to be flexible enough to release fluid and need to have a certain degree of strength in order to sustain the fluid safely. At that same time, they must not be difficult to manipulate during medical procedures. Biocompatibility of PVC results in no bad reaction of this material with the fluid it encloses.

3. **Blood Bags**: Just like IV bags, PVC is very good for blood bags. This material is tough and flexible. PVC blood bags are specifically formulated to contain blood and its components, protecting these constituents to ensure the safety, integrity, and sterility of the contents.

4. **Syringes and Catheters**: Medical tools and equipment like syringes and catheters harness the use of PVC in their manufacture for the reason that the material is strong and easily sterilizable. The equipment needs to be very flexible and tolerant of different tough situations, in order to maneuver different procedures in the medical field with the aim of making sure that patients' safety is put first.

5. **Packaging Films**: PVC films are a definite choice for packaging a number of medical devices and products, ensuring a sterile barrier against contamination. Mostly, this film is laminated with other materials as a composite structure to add value to its protection.

#### Advantages of PVC in Medical Packaging

- Sterilizability Applications where PVC can be sterilized by steam, radiation, and ethylene oxide make medical products made from balanced PVC safe for use.

- Durability Medical packages are kept under hard use and transport, but because of its strength, the safety of the package is not compromised.

- Clarity The transparency of PVC means that product inside can be vision-inspected, a primary consideration in the medical environment.

- **Cost-Effective**: It carries a lower cost compared to other materials and therefore technically provides an economical solution to medical packaging.

- **Chemical Resistance**: It is resistant to chemicals, therefore PVC cannot react with the content of the drugs or fluids contained, thus their safety and efficiency is maintained.

#### Conclusion

It is the special properties of PVC that make it an appropriate material for packaging in the medical field.

These are important imperatives that include some features such as flexibility, strength, clarity, and ability to be sterilized and sterilized that are important for safe and effective packaging of medical products. This paper discusses why, in that regard, with the track record of PVC and its straightforward ability, it is expected to remain a prominent member of the medical packaging industry into the future as the medical industry continues to evolve.

These are important imperatives that include some features such as flexibility, strength, clarity, and ability to be sterilized and sterilized that are important for safe and effective packaging of medical products. This paper discusses why, in that regard, with the track record of PVC and its straightforward ability, it is expected to remain a prominent member of the medical packaging industry into the future as the medical industry continues to evolve.