TL-PS-505 The PS Films Role in Thermoforming Packaging for Pharmaceuticals

2024-08-16 11:50Title: The PS Films Role in Thermoforming Packaging for Pharmaceuticals

The pharmaceutical industry is concerned with packaging to ensure that the safety, integrity, and efficacy of the products are maintained from the sites of manufacture to their final delivery and use. Of the many materials that go into making a package, PS films have emerged over the years as good choices, one gaining increased popularity in recent years in thermoforming applications. Basically, the PS films have the ability to offer some very unique properties which make them appropriate for the development of protective, reliable, and cost-effective packaging solutions for pharmaceuticals.

PS Films and Thermoforming: An Overview

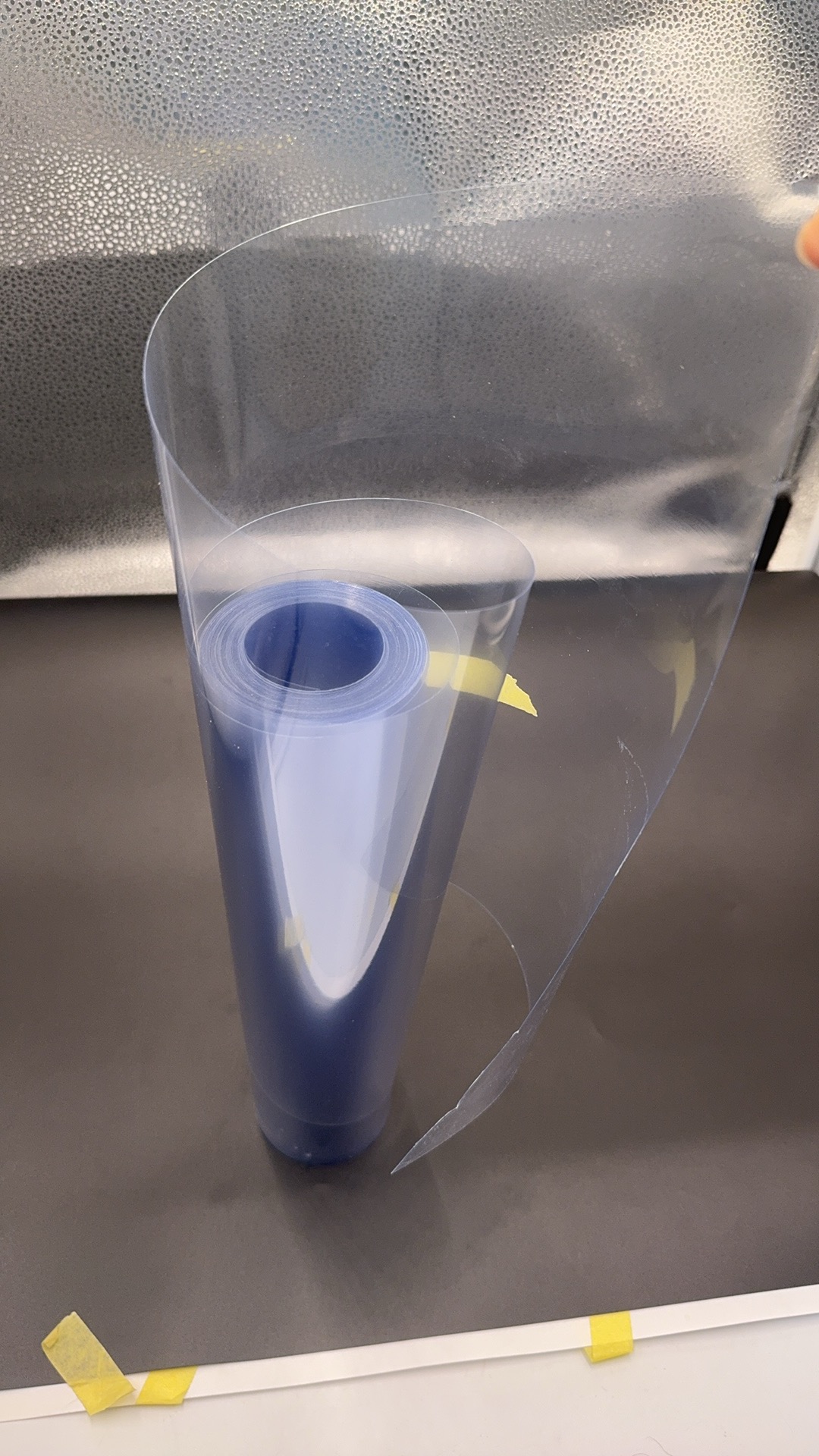

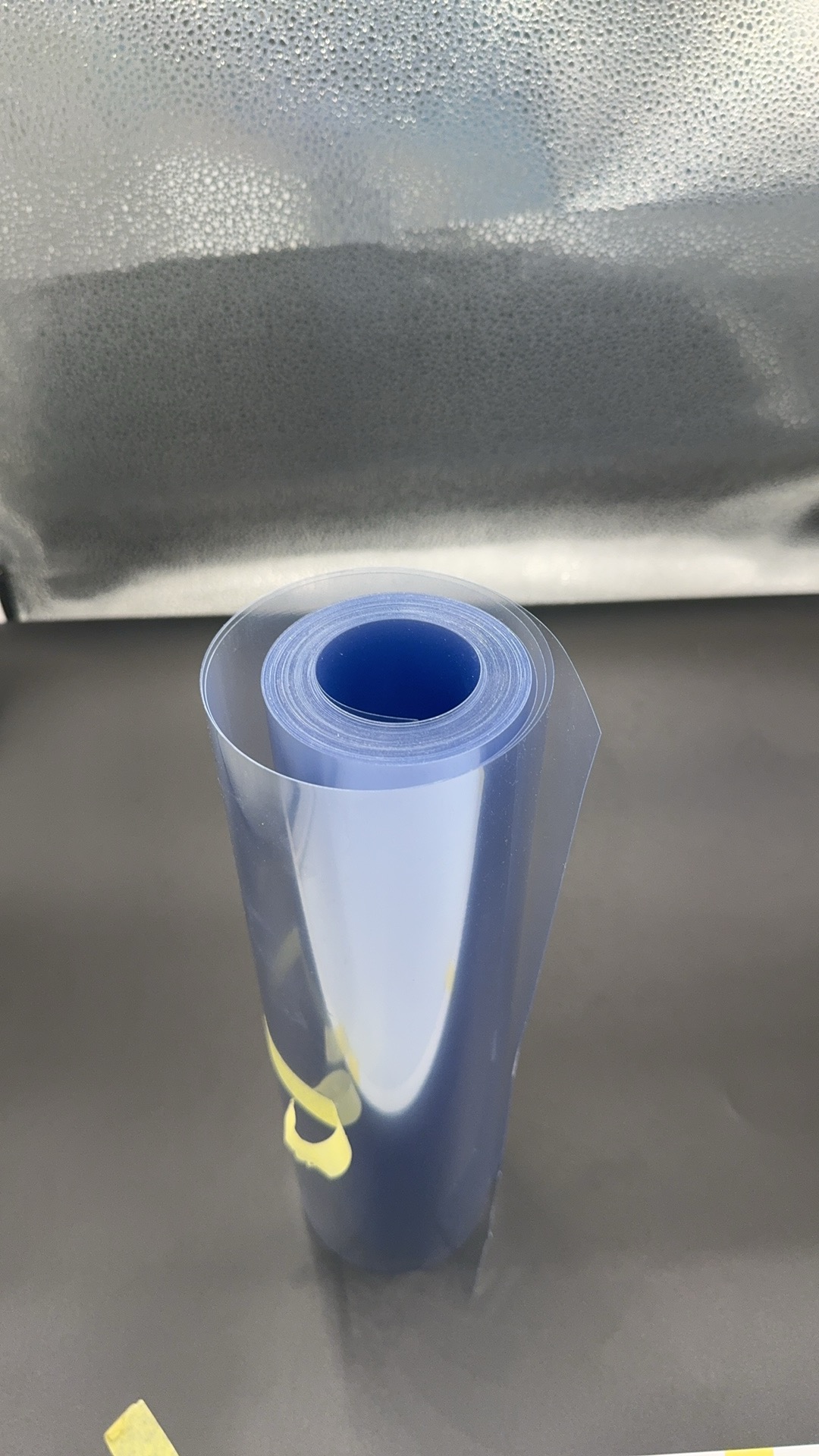

Polystyrene is a rigid, clear, and easily processible polymer. In thin-film form, PS finds a wide range of applications in packaging, particularly in thermoforming. This is a process whereby a plastic film is heated to its pliable temperature before being shaped in a desired form using a mold. Upon cooling, it holds the shape and forms a rigid, protective package.

The forming characteristics of PS films are very excellent, so it can be employed quite easily for thermoforming. They are quite easily molded into complex shapes with intricate detailing, making them very appropriate for pharmaceutical products that need to be contained with great precision and safety.

Some Benefits of PS Films in Pharmaceutical Packaging:

1. Protection and Integrity:

PS films offer outstanding barrier properties against environmental factors, such as moisture, oxygen, and contaminants, which are likely to spoil pharmaceutical products. This is rather significant for the longevity of both effectiveness and shelf life of medicines that are prone to environmental conditions. Moreover, rigidity in PS films means that the packaging remains in an integral state without causing physical damage to the contents during handling, transport, or storage.

2. Clarity and Visibility:

One of the major benefits that PS films bring by default is clarity. For example, in pharmaceutical packaging, a product needs a transparent wrap so one can easily inspect the content without tampering with the package. This gets even more crucial in products like blister packs, where visibility of individual doses needs to be enabled to ensure quality and consumer confidence. Clarity of PS films means transparency of the product and makes them easily recognizable, thus minimizing the possibility of errors. 3. Personalizability and Precision:

The packaging design with PS films can be highly personalized through thermoforming.

PS films can be molded into precise shapes and sizes considering the dimensional specifications of various pharmaceutical products. Whether it's blister packs, trays, or clamshells, PS films can be tailored to meet specific requirements, ensuring a tight fit that prevents movement and consequential damage. Besides, PS films are easily printable with labels, dosage directions, and branding, adding to the functionality and marketability of the product. 4. Cost-Effectiveness: Cost efficiency is a huge factor in pharmaceutical packaging, where large product volumes are involved and need to be packaged consistently but economically.

The cost of manufacturing the films is inexpensive, with a low material cost and productive processing.

The thermoforming process per se is so productive that large volumes of packaging can be produced at a very fast rate and with very little waste.

This makes the use of PS films attractive to pharmaceutical companies in getting the best out of their packaging in terms of quality. 5. Lightweight and Space-Saving: Lightweighting in PS films allows for lower costs in terms of shipment and handling. The thin profile also means less space consumed while storing and transporting them, which again adds up to the economies in using the space available. This becomes more important in the pharmaceutical industry, where maximum storage and least transportation are big concerns. Environmental Considerations:

While PS films have the advantage of good strength and clarity, in the recent past, the user community of these films has raised concerns related to the negative environmental impact of these films in the context of recycling and sustainability. Advancements in recycling technologies shall make recycling of PS films possible, and therefore the environmental footprint shall be further reduced. The ongoing developments of bio-based and/or recyclable PS alternatives offer further opportunities to provide more sustainable packaging solutions in the future.

Conclusion:

Within thermoforming packaging for pharmaceutical products, PS films have remained as one of the most important elements. These have, with the rules of protection of products, clarity, and custom-fitted packaging, made it one of the preferred choices for a lot of the pharmaceutical applications. With increasing changes in the industry, PS films are likely to go on and become one of the major materials that will assure safe, secure, and efficient medication and medical device delivery to consumers.