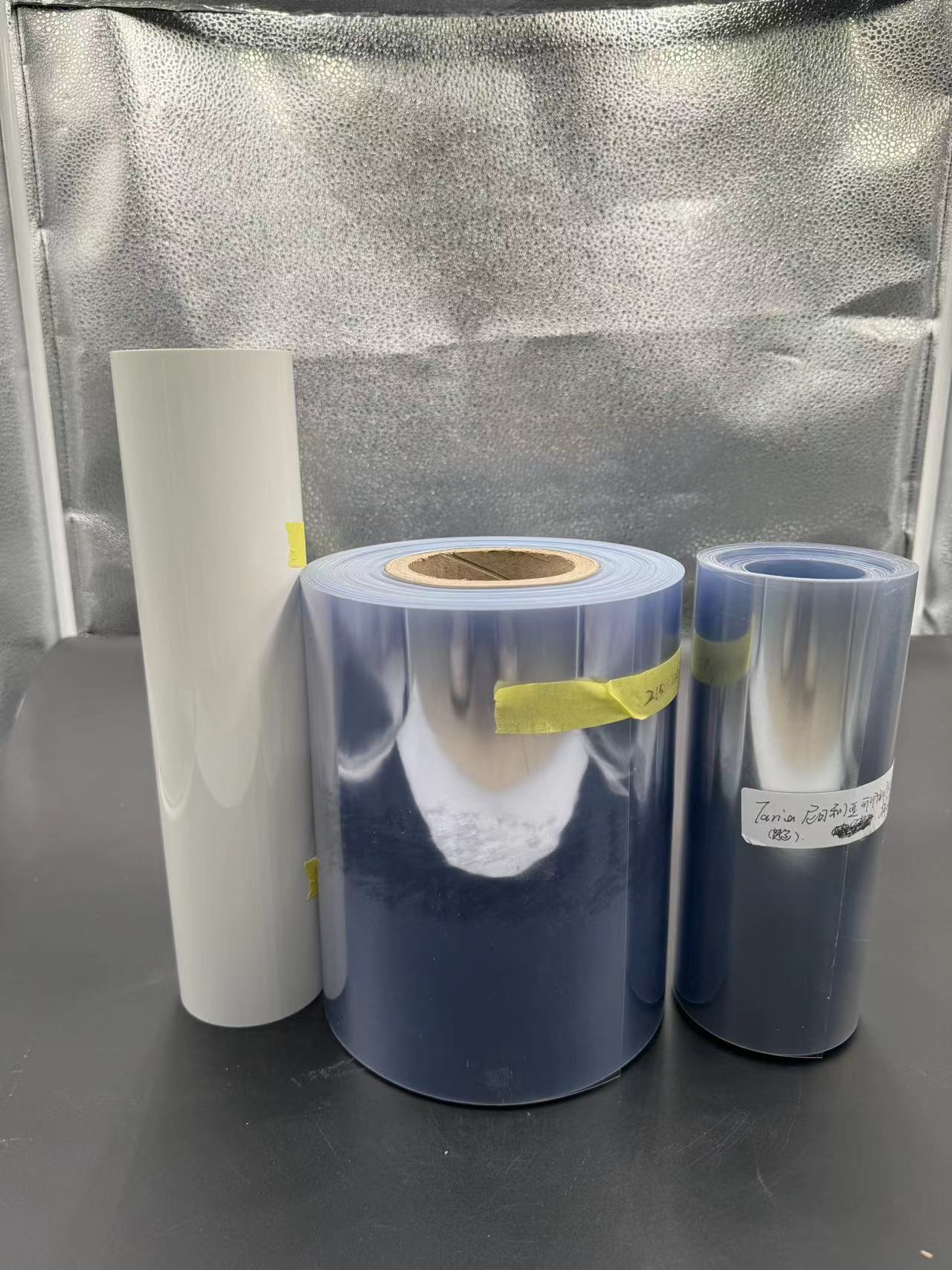

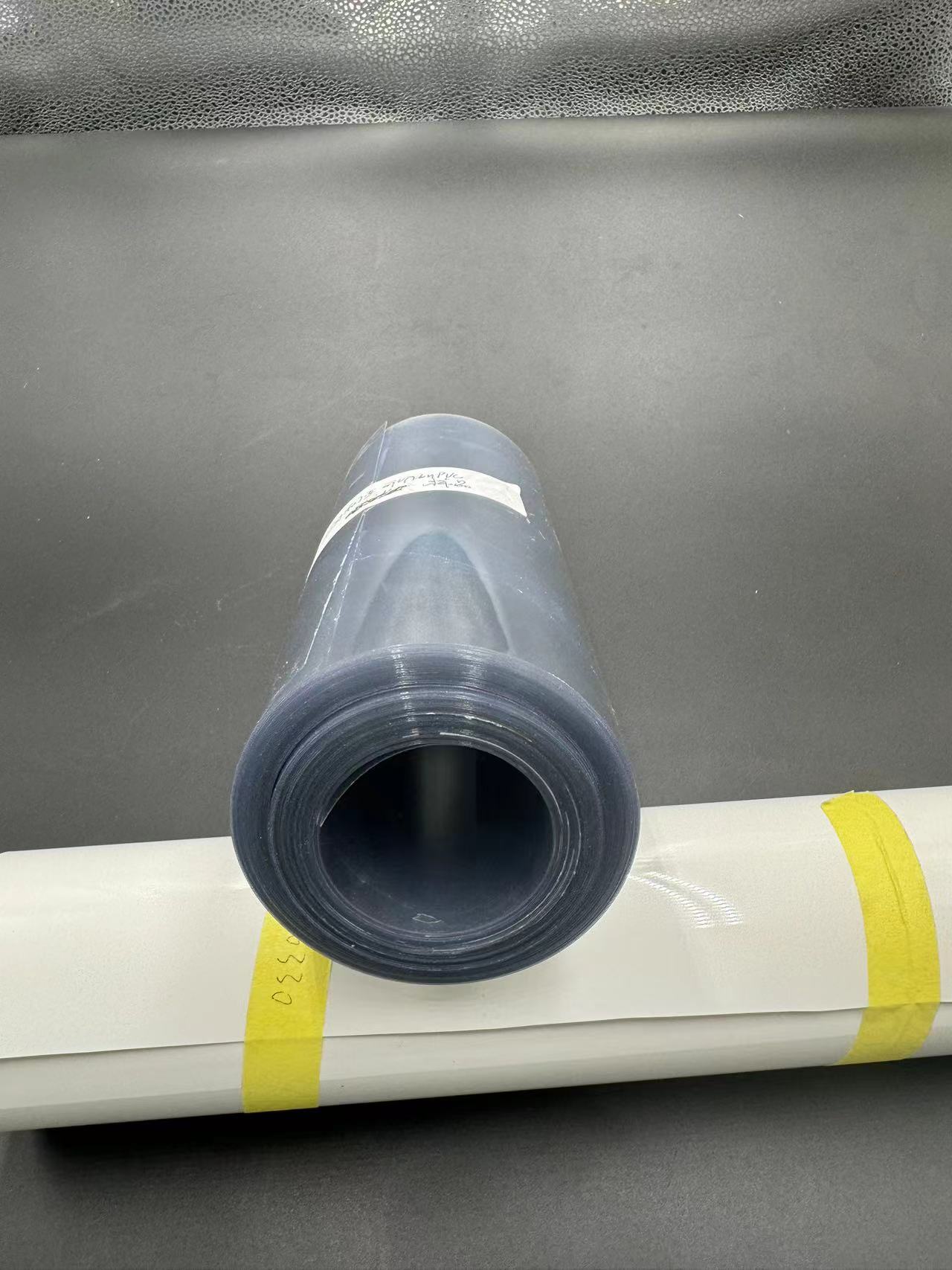

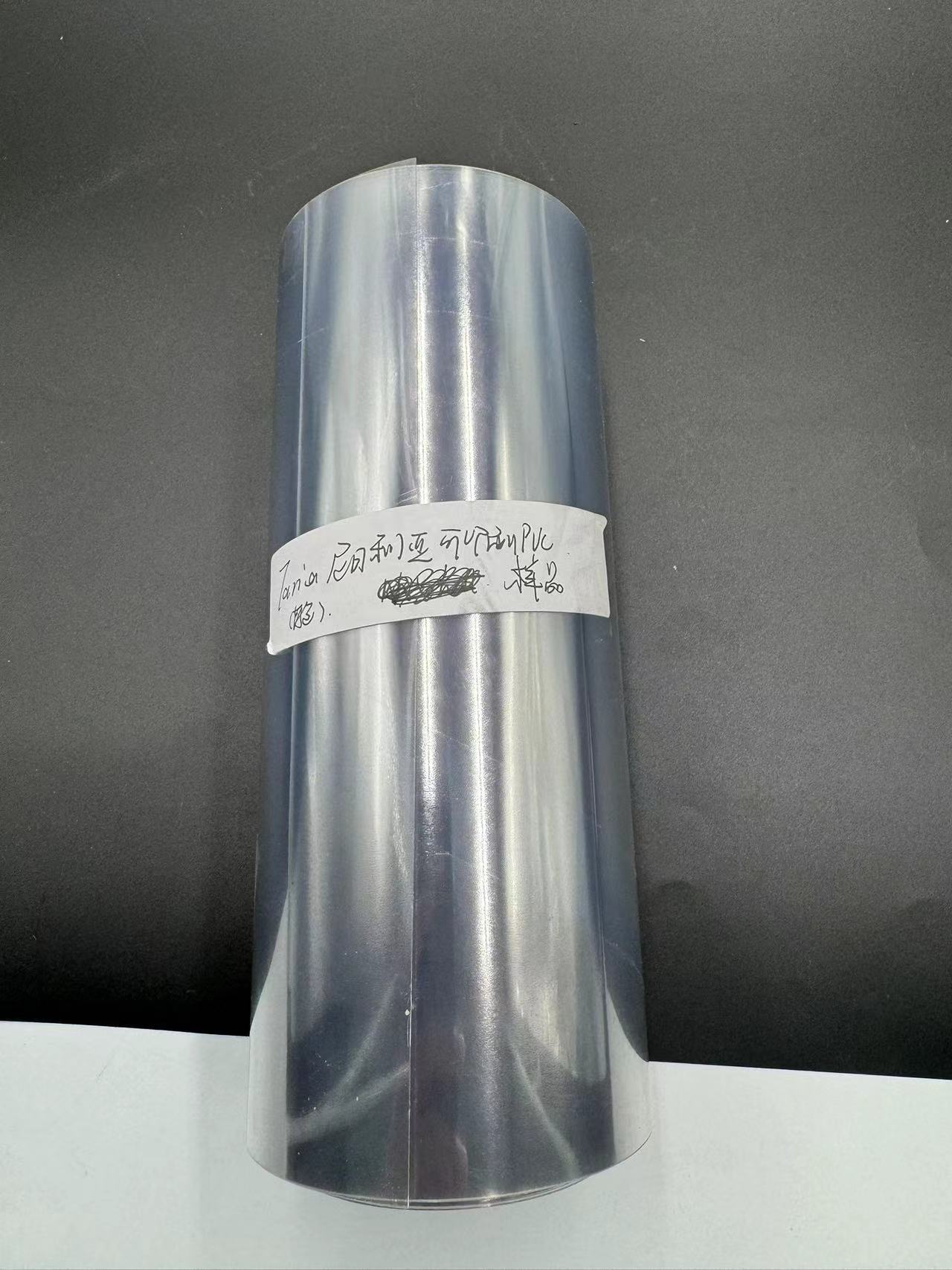

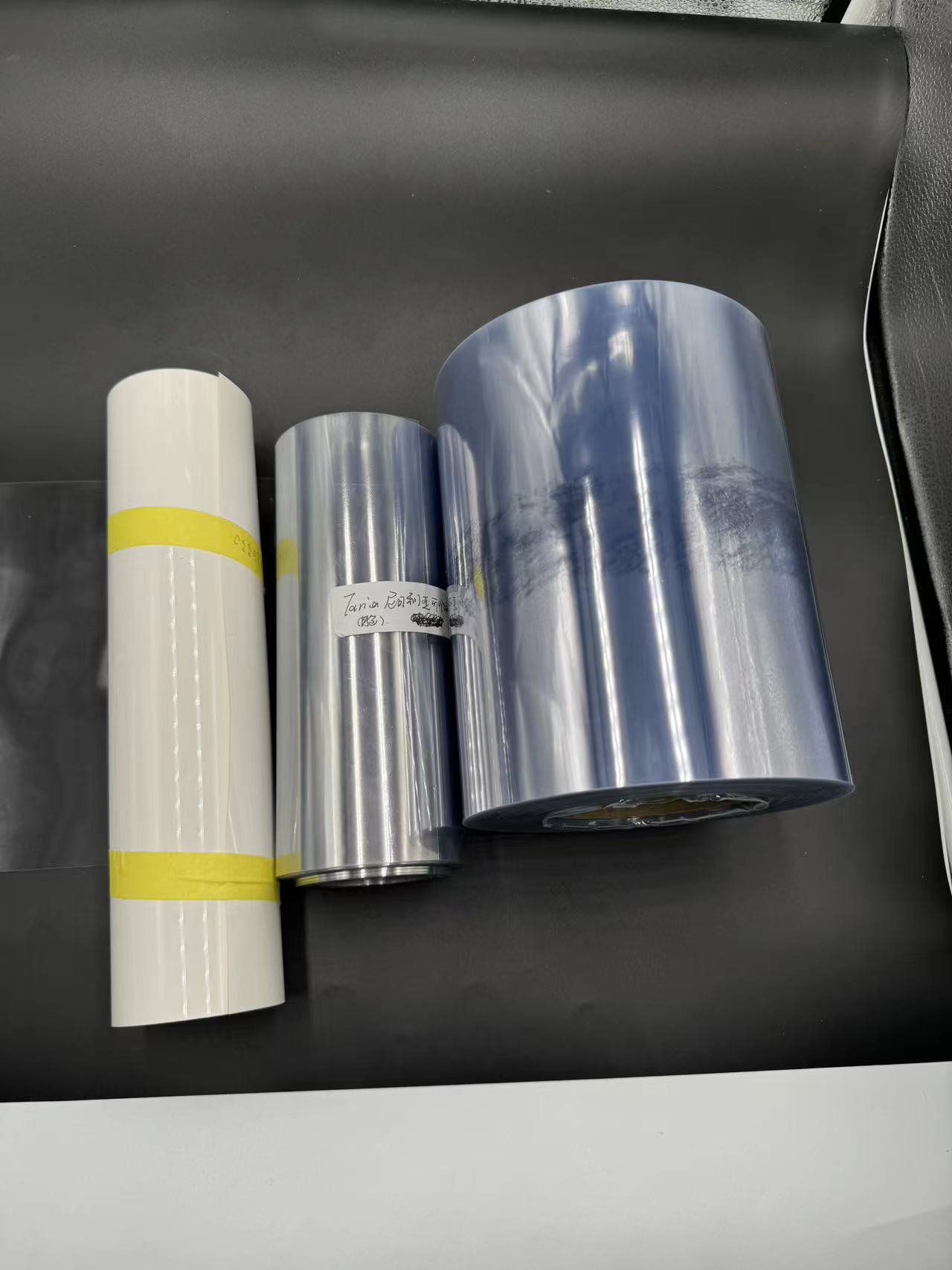

TL-PVC-0030 Printable pvc thermoforming package

2024-09-04 15:41《The Versatile Applications of Printable Transparent PVC Film: From Different Fields to Thermoforming and Pharmaceutical Packaging》

Introduction

Printable transparent PVC film has emerged as a remarkable material with a wide range of applications across various industries. Its unique properties, such as transparency, durability, and printability, make it an ideal choice for different purposes. In this article, we will explore the diverse uses of printable transparent PVC film in different fields, its role in thermoforming processes, and its significance in pharmaceutical packaging.

I. Applications in Different Fields

1. Advertising and Signage

Printable transparent PVC film is widely used in the advertising and signage industry. Its transparency allows for creative designs that can be applied to windows, glass doors, and other transparent surfaces. Whether it's for promoting a brand, announcing an event, or providing directional signage, PVC film offers a sleek and eye-catching solution. The film can be printed with vibrant colors and high-resolution graphics, ensuring maximum visibility and impact.

For example, in retail stores, printable PVC film is used to create window displays that attract customers and showcase products. The transparency of the film allows passersby to see inside the store while still being able to view the promotional messages printed on the film. In addition, PVC film can be used for outdoor signage, such as billboards and banners, as it is weather-resistant and can withstand exposure to sunlight, rain, and wind.

2. Graphic Design and Printing

The printability of transparent PVC film makes it a popular choice among graphic designers and printers. It can be printed using various printing techniques, including digital printing, screen printing, and offset printing. This allows for the creation of high-quality prints with sharp details and vivid colors.

In the field of graphic design, PVC film is used for creating posters, brochures, business cards, and other promotional materials. The transparency of the film can add an element of uniqueness to the design, creating a visually appealing effect. For example, a business card printed on transparent PVC film can have a professional and modern look, making it stand out from traditional paper business cards.

In printing, PVC film is often used for packaging labels and stickers. The transparency of the film allows the contents of the package to be visible while still providing important information such as product name, description, and barcode. PVC stickers are also popular for decorating laptops, phones, and other electronic devices, as they are durable and can be easily removed without leaving any residue.

3. Interior Design and Decoration

Printable transparent PVC film has found its way into the interior design and decoration industry. It can be used to create unique wall decals, window films, and furniture overlays. The transparency of the film allows it to blend seamlessly with the existing decor while adding a touch of elegance and creativity.

For example, wall decals made of PVC film can be used to transform a plain wall into a work of art. The film can be printed with various designs, such as patterns, quotes, or images, and applied directly to the wall. Window films made of PVC film can be used to add privacy to a room while still allowing natural light to enter. Furniture overlays made of PVC film can be used to protect and decorate furniture, giving it a new look without the need for expensive renovations.

4. Industrial Applications

In addition to its applications in advertising, graphic design, and interior decoration, printable transparent PVC film also has several industrial uses. It is used in the manufacturing of products such as protective covers, insulation materials, and gaskets.

For example, PVC film can be used to create protective covers for machinery and equipment, protecting them from dust, moisture, and scratches. It can also be used as insulation material in electrical applications, providing protection against heat and electrical shocks. In the automotive industry, PVC film is used for making gaskets and seals, ensuring a tight fit and preventing leaks.

II. Thermoforming

Thermoforming is a process in which a plastic sheet is heated and then formed into a specific shape using a mold. Printable transparent PVC film is an ideal material for thermoforming due to its flexibility and heat resistance.

1. Process of Thermoforming with PVC Film

The thermoforming process with PVC film typically involves the following steps:

• Heating: The PVC film is heated to a specific temperature, usually between 150 and 200 degrees Celsius. This softens the film and makes it pliable.

• Forming: The heated film is then placed over a mold and vacuum or pressure is applied to form it into the desired shape. The mold can be made of various materials, such as metal, wood, or plastic.

• Cooling: Once the film has been formed, it is cooled to solidify the shape. This can be done by spraying water or using a cooling tunnel.

• Trimming: The excess film is trimmed off to obtain the final product.

2. Applications of Thermoformed PVC Products

Thermoformed PVC products have a wide range of applications in different industries. Some of the common applications include:

• Packaging: Thermoformed PVC trays and blisters are widely used for packaging products such as electronics, cosmetics, and pharmaceuticals. The transparency of the PVC film allows the contents to be visible, while the formed shape provides protection and stability.

• Automotive: Thermoformed PVC parts are used in the automotive industry for interior trim, dashboard panels, and door panels. The lightweight and durable nature of PVC make it an ideal material for these applications.

• Medical: Thermoformed PVC products are used in the medical field for items such as surgical trays, instrument cases, and disposable medical devices. The sterilizable nature of PVC makes it suitable for use in healthcare settings.

III. Pharmaceutical Packaging

The pharmaceutical industry has strict requirements for packaging materials to ensure the safety and integrity of drugs. Printable transparent PVC film meets these requirements and is widely used in pharmaceutical packaging.

1. Properties of PVC Film for Pharmaceutical Packaging

• Transparency: The transparency of PVC film allows for easy inspection of the contents, ensuring that the drugs are intact and free from contamination.

• Barrier Properties: PVC film provides a good barrier against moisture, oxygen, and light, which can degrade the quality of drugs. This helps to extend the shelf life of the drugs.

• Printability: The film can be printed with important information such as drug name, dosage, expiration date, and batch number. This helps in identification and traceability of the drugs.

• Sterilizability: Some types of PVC film can be sterilized using methods such as gamma irradiation or autoclaving, making them suitable for packaging sterile drugs.

2. Applications in Pharmaceutical Packaging

• Blister Packaging: PVC film is commonly used for blister packaging of tablets, capsules, and other solid dosage forms. The blisters provide protection against physical damage and moisture, while the transparency of the film allows for easy inspection of the drugs.

• Strip Packaging: PVC film is also used for strip packaging of drugs. The film can be printed with patient information and dosage instructions, making it convenient for use.

• Bottles and Vials: PVC film can be used to create labels for bottles and vials. The transparency of the film allows the contents to be visible, while the printed information provides important details about the drug.

Conclusion

Printable transparent PVC film is a versatile material with a wide range of applications in different fields. Its transparency, durability, and printability make it an ideal choice for advertising, graphic design, interior decoration, and industrial applications. In thermoforming, PVC film offers flexibility and heat resistance, allowing for the creation of various shapes and products. In pharmaceutical packaging, PVC film meets the strict requirements for safety and integrity, providing a reliable packaging solution. With its many advantages, printable transparent PVC film is sure to continue playing an important role in various industries.