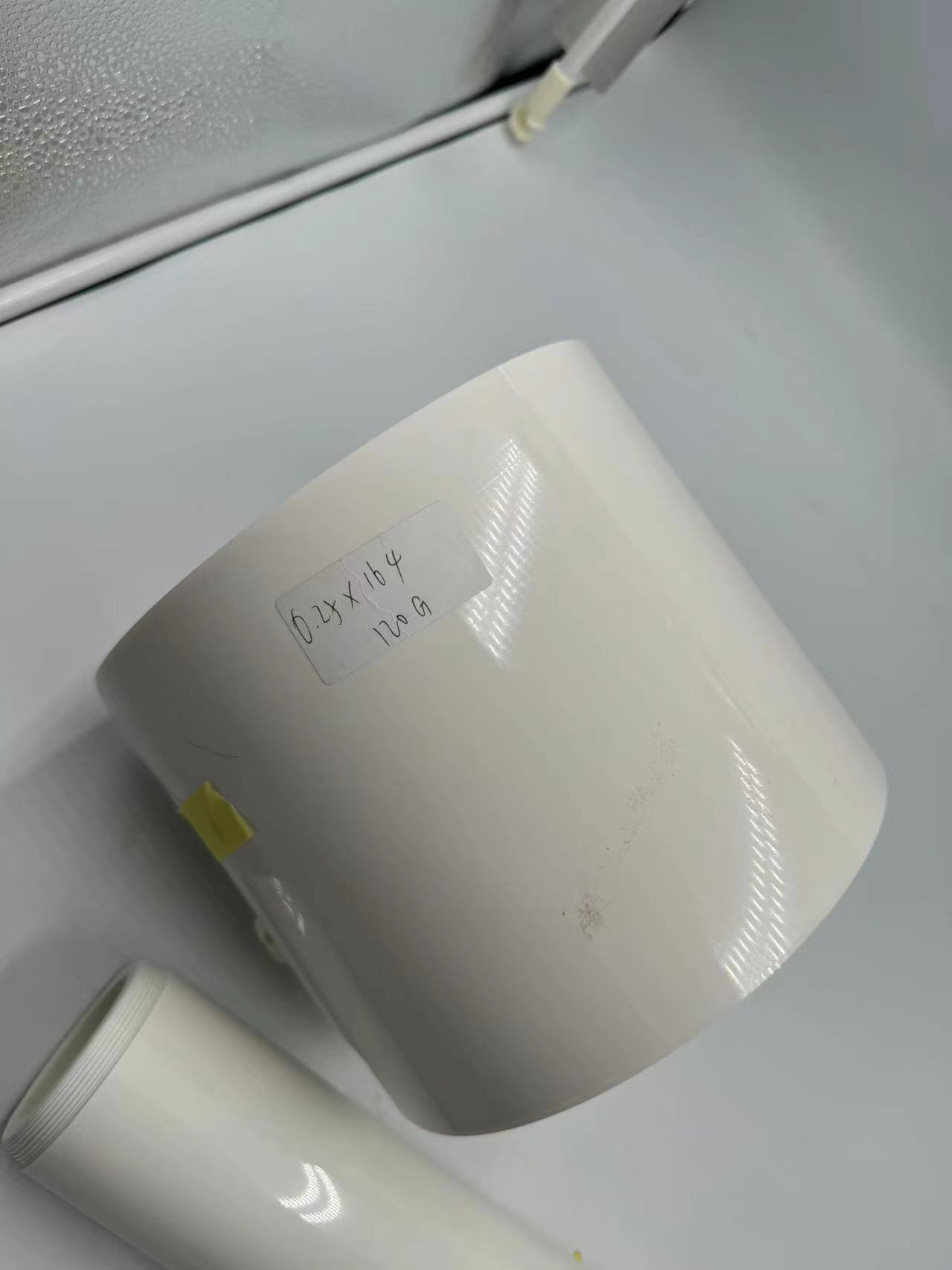

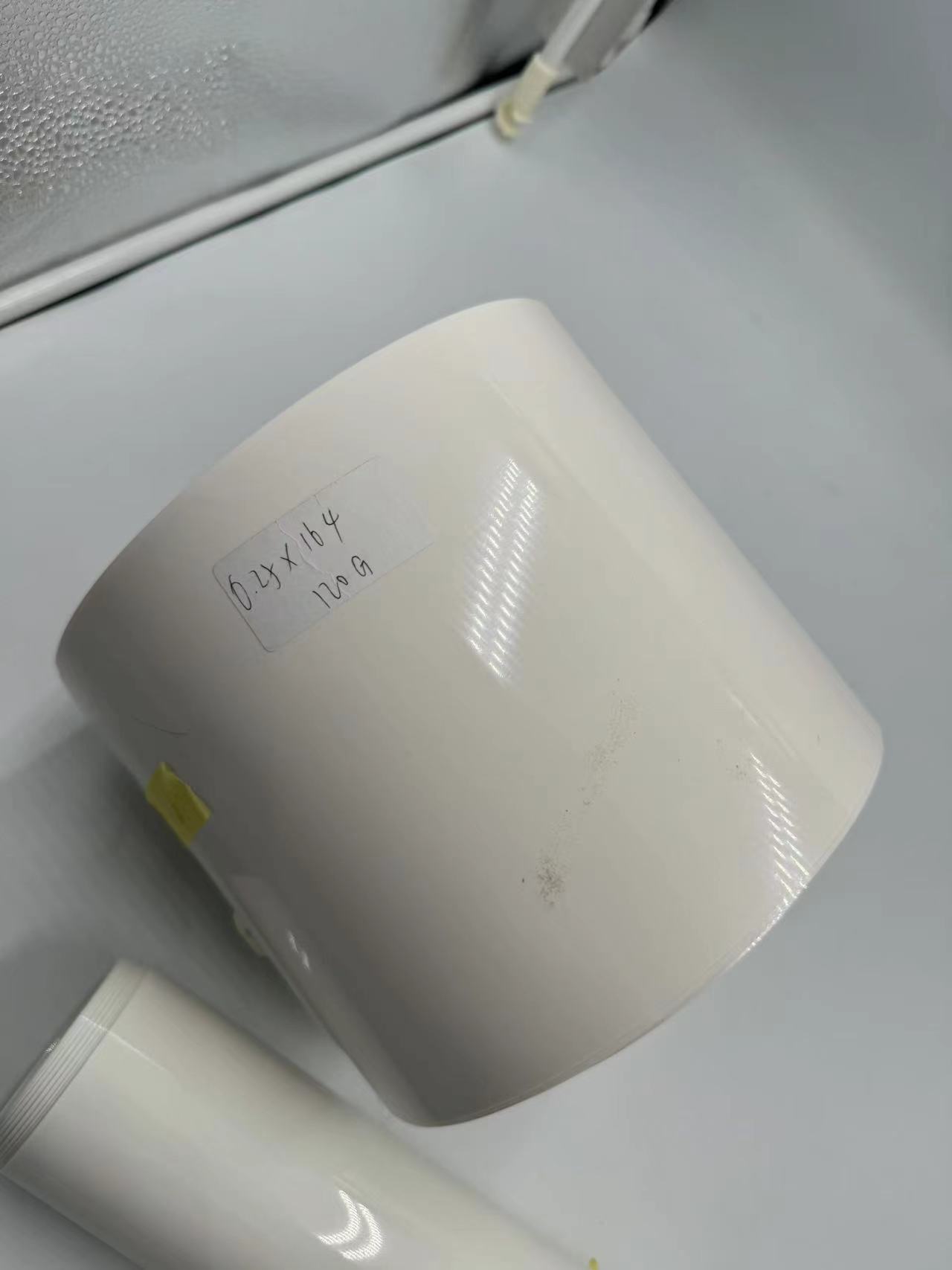

TL-PVDC-0020 THE PVDC FILM FOR pharmaceutical

2024-08-23 14:16The Use of White PVDC in Pharmaceutical Blister Packaging

1. Introduction

Pharmaceutical packaging is essential in the maintaining quality, efficiency, and safety in drugs. White PVDC (Polyvinylidene Chloride) is a substantial material that has gained momentum in pharmaceutical blister packaging, as it unfolds a bundle of advantages while adhering to all the strict requirements of the industry.

2. Properties of White PVDC

White PVDC is an excellent barrier material. It prevents the penetration of moisture, oxygen, and various gases, which may reduce or spoil pharmaceuticals. Its low permeability assures a long shelf life and stability of the drugs in their respective packagings.

It is inert, and this property makes it non-reactive with most pharmaceutical compounds, securing thereby the integrity and purity of the drugs. The mechanical strength in white PVDC ensures strong blister packs, resistant enough to handling and transportation without losing the integrity of the package.

3. Moisture and Oxygen Barrier

One of the critical roles of packaging in pharmaceuticals is protection against the ingress of moisture and oxygen. The improved barrier properties to moisture in white PVDC prevent moisture absorption, which is necessary for drugs that are hygroscopic and prone to degradation due to humidity.

The oxygen barrier function of white PVDC can preserve the potency of drugs sensitive to oxidation. It provides protection against oxygen, hence increasing the shelf life and assuring therapeutic efficiency of the pharmaceuticals.

4. Chemical Resistance

Most pharmaceuticals have complex chemical compositions. White PVDC is highly chemically inert, hence will not react or interfere with the active ingredients or excipients of the drugs. This is a very vital property to prevent any change in the drug properties or the formulation.

5. Thermal Stability

The package material goes through ranges of temperatures during the manufacture and sterilization of products. White PVDC has excellent thermal stability, thus finding itself able to support heat treatments without severe changes in the physical or chemical nature of the material.

6. Blister Design and Formulation

White PVDC can be thermoformed into different, very complex blister designs to accommodate various drug shapes and sizes, various sizes, and dosages. Due to the material's flexibility, one can devise specialized blister packs that will tightly fit the drugs and not move around in the pack, thus reducing the risk of damage.

7. Child-Resistant and Senior-Friendly Package

Safety Features: Pharmaceutical packaging must also incorporate safety features. White PVDC can be combined with child-resistant designs to eliminate the possibility of accidental ingestion. Further, it can be made senior-friendly, with easy-open features for the elderly.

8. Manufacturing Processes

The manufacturing of white PVDC blister packs involves applying accurate thermoforming techniques coupled with stringent quality control measures. State-of-the-art manufacturing equipment is used to ensure homogeneous quality and to congregate to rigorous regulatory requirements.

9. Regulatory Compliance

The pharmaceutical industry is heavily regulated, and the packaging material must adhere to a broad array of regulations. White PVDC goes through a myriad of tests in order to comply with the regulatory requirements for the safety and efficacy of the drugs packaged.

10. Cost Considerations

While providing high-quality protection, white PVDC also offers a cost-effective solution for pharmaceutical packaging. The excellent performance and durability, along with the efficient manufacturing processes, make the material cost-effective.

11. Environmental Impact

In an age of environmental consciousness, the ecological footprint of packaging materials is of concern. The recyclability of white PVDC and potential ways of sustainable disposal options are underway to reduce its impact on the environment.

12. Future Trends and Developments

The pharmaceutical packaging industry has been in a continuous state of evolution. Research and development efforts are focused in terms of improving properties of white PVDC, new formulations, and smart packaging technologies that allow better traceability and monitoring of drugs.

13. Conclusion

White PVDC has been a very useful material in pharmaceutical blister packaging of medicines due to its added protection, compatibility, and design flexibility. With further innovation evolution, white PVDC will grow more prominent in its roles with regulatory requirements in the delivery of the safe and effective pharmaceutical to patients.