TL-ABC-402 ANTI-STATIC ABS Texture sheet ABS Board

1. Electronic Enclosures

One of the common uses of these ABS materials is in the production of most enclosures for a lot of today's electronic devices. The enclosures actually isolate a sensitive component from the external environments and protect it against electrostatic discharges. Some manufacturers are capable of enhancing this natural dissipative quality of the material by adding conductive or dissipative additives into the ABS formulation to offer better protection for the internal electronics against static charges.

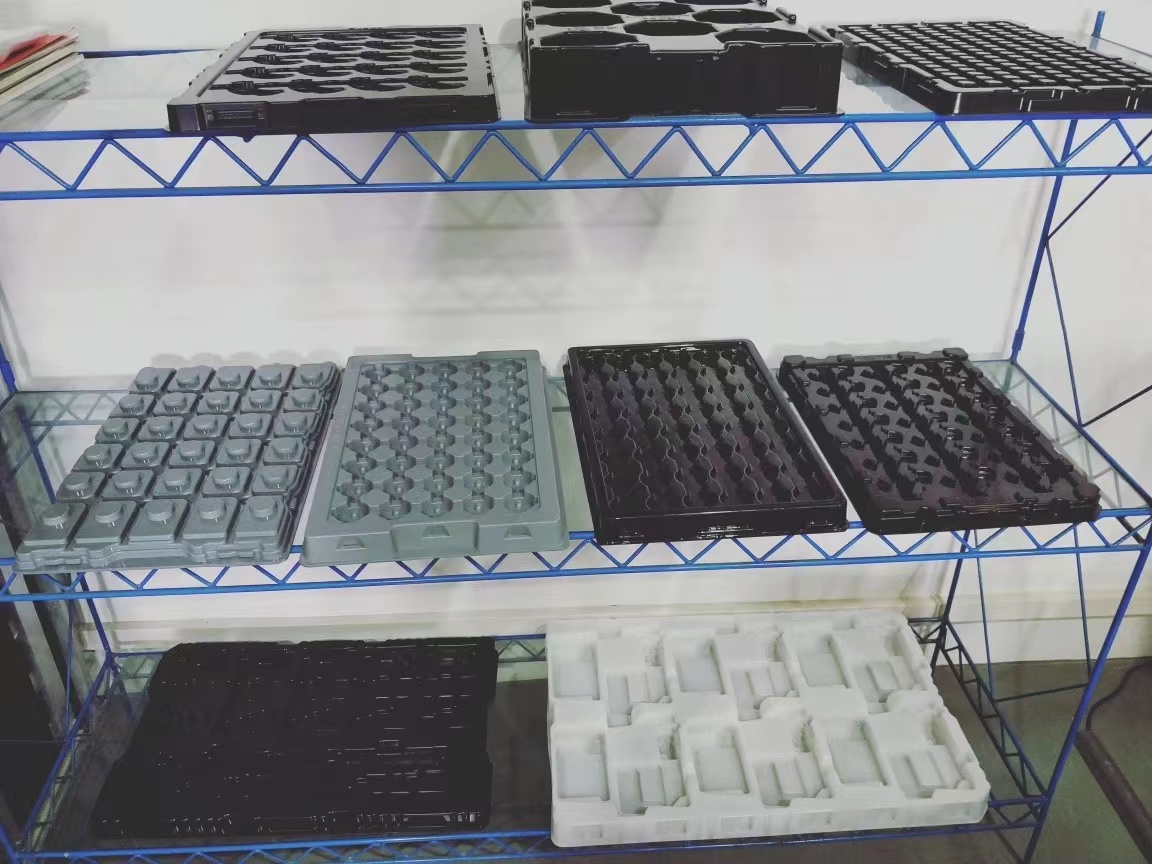

2. Anti-Static Trays and Packaging

Anti-static trays and packaging are an integral part of manipulating sensitive components in the electronics industry. This is so because anti-staticing agents can be applied to ABS to successfully produce such trays. These agents reduce the buildup of electrostatic charges on the surface of the ABS material and therefore eliminate the possibility of ESD during handling and storage.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Applications of ABS Materials in Electrostatic Discharge Protection

Introduction

Acrylonitrile Butadiene Styrene, commonly referred to as ABS, is a thermoplastic polymer that finds wide applications due to its workability, toughness, and shock resistance. Between many of the great applications of ABS materials is electrostatic discharge protection. Since ESD can cause large and critical damage to electronic components, effective protection is important at the design and manufacturing stages of an electronic device. With these concerns, the application of ABS materials is increasingly being put into practice, offering practical solutions for the management of electrostatic charges.

Characteristics of ABS Materials

ABS is a combination of three key components: acrylonitrile, butadiene, and styrene. From the combination of these three monomers, ABS derives a host of other useful features, which include the following:

• Impact Resistance: In this respect, ABS has well-established high impact strength. This will protect the electronic components against mechanical damage.

• Thermal Stability: It retains its structure over a wide temperature range, making it appropriate to be used in various kinds of environments.

• Easy to Fabricate: ABS is readily molded, extruded, and machined. This will help in manufacturing parts and components of complex form with high accuracy.

ESD Protection Applications

1. Electronic Enclosures

One of the common uses of these ABS materials is in the production of most enclosures for a lot of today's electronic devices. The enclosures actually isolate a sensitive component from the external environments and protect it against electrostatic discharges. Some manufacturers are capable of enhancing this natural dissipative quality of the material by adding conductive or dissipative additives into the ABS formulation to offer better protection for the internal electronics against static charges.

2. Anti-Static Trays and Packaging

Anti-static trays and packaging are an integral part of manipulating sensitive components in the electronics industry. This is so because anti-staticing agents can be applied to ABS to successfully produce such trays. These agents reduce the buildup of electrostatic charges on the surface of the ABS material and therefore eliminate the possibility of ESD during handling and storage.

3. Workstation Surfaces

ABS is used again in the design of ESD-protected workstation surfaces. These can include surfaces used in environments associated with the assembly and repair of electronics. By adding conductive ABS materials to workbench tops and flooring, manufacturers create a surface that helps dissipate static charges, thus reducing the chances of ESD incidents in sensitive work areas.

4. Static Control Accessories

Much of the static control accessories, such as wrist straps and grounding mats, are made using ABS materials. These will provide proper grounding to ensure that people handling sensitive electronic components are not generating static electricity, which would reduce the possibility of ESD. Durability and moldability characteristics make ABS quite useful in producing these accessories.

5. ESD Safe Containers

In most cases, ABS finds applications in producing containers that are designed to serve as safe storage and transport media for electronic components. Many a time, features such as conductive liners or coatings are provided inside the container to dissipate static charges and avoid potential ESD damage to the components stored.

Why ABS for ESD Protection?

- Cost Effectiveness: The prices of ABS are considerably low compared with other materials used for the same process of ESD protection; thus, it is a cost-effective option for any manufacturer.

- Versatility: Due to the possibility of modification by means of additives and treatments, ABS will allow for very large ranges of ESD protection applications.

- Durability: The strength of ABS itself secures long-lasting performance and reliability in the most varied ESD-sensitive environments.

Conclusion

ABS materials form a significant element in the domain of electrostatic discharge protection by delivering efficient solutions for the protection of electronic components and assemblies. This makes it find wide applications in ESD protection for use in enclosures, packaging, workstation surfaces, and static control accessories, all due to excellent impact resistance, thermal stability, and ease of fabrication. Growing electronic device complexity and sensitivity will raise the demand for ABS in its role of reliably protecting these devices to increase life and performance in electronics.

Within 15-20 days after received payment...more