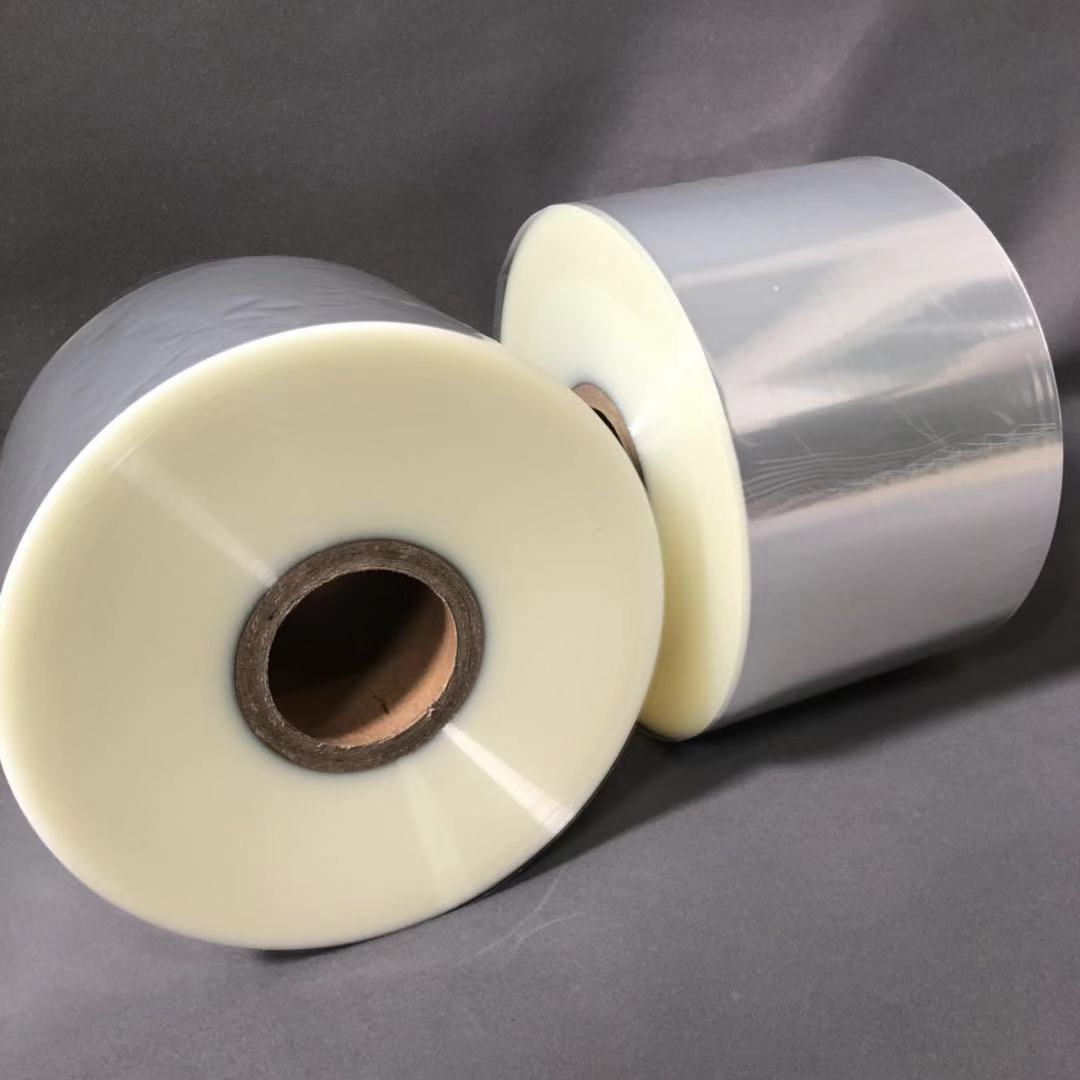

TL-BOPP-311 BOPP FILM BOPP heat film BOPP Film BOPP membrane

BOPP Film for Practical Packaging: An Essential Material in Modern Packaging Solutions

Introduction

BOPP film has become one of the cornerstone materials in the industry due to its versatility, durability, and inexpensiveness. Known for its high mechanical and optical properties, biaxially oriented polypropylene film today finds use in a wide spectrum of applications related to practical packaging, from food to labeling. In this paper, the characteristics, advantages, and uses of BOPP film in practical packaging, along with sustainability issues, will be discussed.

What is BOPP Film?

BOPP film is a type of plastic film that has been made to stretch in machine direction and across the machine direction while it is under formation. As a result of this biaxial orientation, BOPP film developed properties that make it stronger, clearer, and more versatile than regular polypropylene film. Different thicknesses of BOPP films with varying finishes and surface treatments can also be made up according to specific packaging requirements.

Key Characteristics of BOPP Film

1. High Clarity and Gloss: Since BOPP film gives very good clarity with a high gloss finish, the material finds a huge application in the field of packaging where end-product visibility and shelf appeal are prime necessities. This material is transparent and clearly displays the product to the consumers; this is especially so in food packagings.

2. Mechanical Strength: The BOPP film shows excellent mechanical properties such as high tensile strength, tear resistance, and puncture resistance. It is suitable for use in packaging products that require robust protection during handling and transportation.

3. Barrier Properties: The BOPP film offers excellent protection against the penetration of moisture, oxygen, and other gases. Hence, it is very suitable in the packaging of food products that require freshness and protection from the elements.

4. Heat Sealability: BOPP film can be heat-sealed and is, therefore, processable on a wide variety of packing machines. This thus comes in handy in the production of secure and tamper-evident packages that guarantee safety to the product.

5. Light Weight: Despite the strength, BOPP film is lightweight, which helps cut down on freight and material costs. Lightness with its blend of strength makes it an economical option in large volumes of packaging.

BOPP Film: Benefits in Real-world Packaging Applications

1. Versatility: BOPP film's area of application ranges from food and beverages to pharmaceutical and personal care product packaging. Its capacity for lamination, printing, and coating makes it an extremely versatile material in the packaging industry.

2. Cost-Effective: Relatively inexpensive to produce, hence a cost-effective solution for packaging without ever comprising the quality of the same. The process of production is efficient and material-efficient; hence, it is less costly to the packager.

3. Aesthetic Appeal: High clarity and gloss of BOPP film enhance the product's appearance in a package. This will be important in a retail environment where attractive packaging tends to sway consumer purchasing decisions.

4. Ecological Influence: BOPP film is recyclable, and enhancements in recycling technology make it evermore possible to recycle BOPP wastes into new products. Besides, manufacturing BOPP film uses less energy than other plastic films; hence, it is able to offer a reduced carbon footprint.

5. Printable Surface: The BOPP film surface is very excellent for printing high-resolution graphics and text. It is why it makes for one of the preferred choices for packaging brands, product information, or promotional materials.

Applications of BOPP Film in Practical Packaging

1. Food Packaging: Food packaging forms one of the major uses of BOPP films. It is used in the packaging of snack foods, confectionery, baked goods, and fresh produce, among others. This film retains freshness in food owing to its barrier properties, while increasing transparency and gloss that further add to its presentation.

2. Labels and Wraps: Due to the clarity, printability, moisture, and chemical resistance, this film finds many uses in labeling applications. It is also used as a shrink wrap for bundling products, offering protection and ease of handling.

3. Lamination: In most cases, BOPP film is being laminated with other materials to achieve flexible packaging structures with enhanced properties. Thus, laminated BOPP films are used for the packaging of products such as coffee, pet food, and personal care.

4. Stationery and Overwraps: In the manufacture of stationery products such as clear book covers, adhesive tapes, and overwraps for CD cases, DVDs, etc.

5. Medical and Pharmaceutical Packaging: The chemical resistance and barrier properties make BOPP film applicable in the packaging of medical devices, pharmaceutical products, and other related healthcare items which must be protected from contamination.

Sustainability and Environmental Considerations

In increased demand for sustainable packaging solutions puts BOPP film in the limelight since it is recyclable and has a relatively lower environmental impact than other available packaging materials. BOPP films could be recycled into useful products, hence decreasing the use of virgin material and offering a circular economy. Other than the light weight of this material that reduces the quantum of material used, thereby reducing its environmental footprint, it has other features that go in its favor for packaging applications.

Moreover, manufacturers are increasingly developing BOPP films that are biodegradable or compostable; this therefore dispels the fears of consumers and industries concerning plastic wastes. These developments enable the promotion of BOPP films as a more sustainable option in packaging.

Conclusion

BOPP film is, in a fundamental sense, a very important material in modern packaging—it offers strength, clarity, and cost-effective relief in a host of broadly applicable practical packaging uses. Its wide range of applications means that it can be found in industries ranging from food and beverages through to pharmaceuticals and personal care. As the thinking shifts toward greater sustainability, then clearly its recyclability and potential for eco-friendly alternatives will undoubtedly raise the appeal for BOPP film. If innovation in technology and material science is increased, then BOPP film will dominate the front lines of the packaging industry for many years.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Product Attributes

:

:

:

:

: food, flower, cloth,bag, milk,

: smoothly

:

:

: transparent

:

:

:

:

Supply Ability & Additional Information

:

:

:

:

:

:

:

:

:

Within 15-20 days after received payment...more