TL-BOPP-308Application of BOPP in Precision Electronics Packaging

4. Electronics Packaging Trays: These are one of the most common kinds of packaging trays produced with BOPP. These trays are specially designed to securely house the contents, jigs, and other components for keeping and during transit. The exception of the innate antistatic property coupled with ease of thermoforming for BOPP makes the material best suited for devising custom tailored packaging that meets the excruciatingly high standards set by the electronics industry.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Download

Application of BOPP in Precision Electronics Packaging

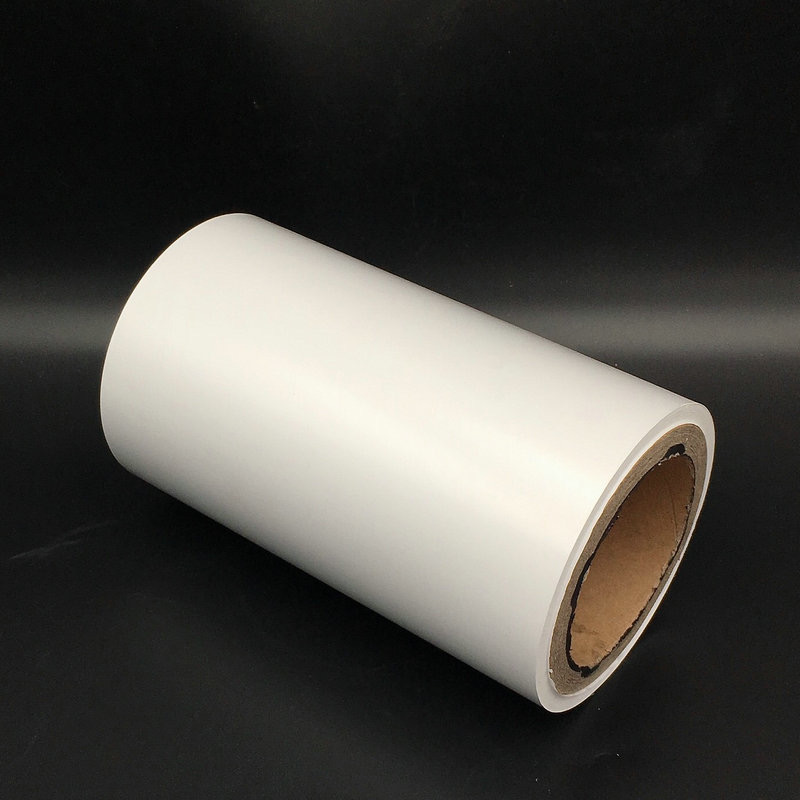

Biaxially Oriented Polypropylene (BOPP) has found an imperative role in packaging applications of precision electronics due to its splendid characteristics. Being a flexible and efficient material, it has consequently found various niches in the electrnic industry, especially in the packaging field. Special Key Properties of BOPP for Precision Electronics Packaging

1. Vacuum Thermoforming: BOPP performs extremely well in vacuum thermoforming processes, particularly in those where high demands on food packaging are required. Temperature resistance and freeze tolerance make this material ideal for food packaging under non-baked applications, even for microwaveable and frozen foods. These very features contribute to its use in the electronics industry for the creation of strong, dependable packaging solutions for sensitive electronic components.

2. Transparency: Good transparency is one of the features of BOPP, and for this reason, it is widely suggested in packaging applications that require the products inside to be seen. For precision electronics purposes, this transparency makes it easier for identification and inspection of components without tampering with the package, thus reducing contamination risks and product spoilage.

3. Antistat Properties: One of the most important features that BOPP has toward the electronics industry is that BOPP is not very inviolable as it can be treated with antistatic agents for keeping properties against static charge, which is vital towards protection of electrostatic discharge—ESD to sensitive electronic parts. In this way, BOPP can make for an excellent option for packing trays that would be used to store and transport precision electronics, thus making components safe from static damage.

4. Electronics Packaging Trays: These are one of the most common kinds of packaging trays produced with BOPP. These trays are specially designed to securely house the contents, jigs, and other components for keeping and during transit. The exception of the innate antistatic property coupled with ease of thermoforming for BOPP makes the material best suited for devising custom tailored packaging that meets the excruciatingly high standards set by the electronics industry.

Conclusion

BOPP, in light of its high level of transparency, good thermoforming characteristics, and antistatic features, has made the best material for the packaging of electrostatic-sensitive precision electronics. With the better demand for more reliable and high-efficient packaging in electronics, BOPP has started to pay more importance to the process of guaranteeing that electrostatic-sensitive precision electronics are safely and well-packaged from production to end-use.