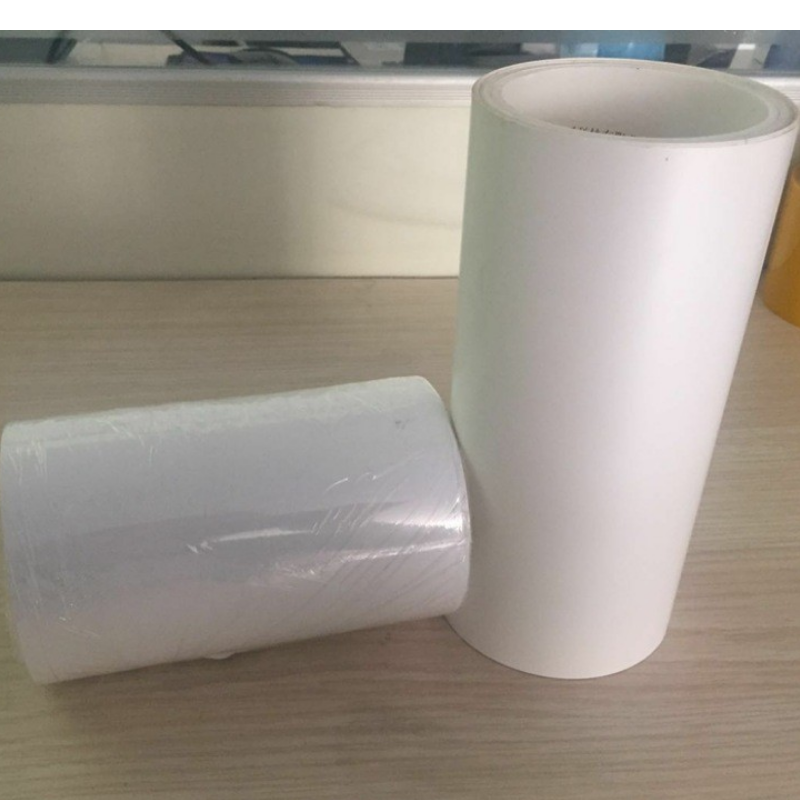

PETG sheet base environmentally friendly materials

PETG sheet base materials are all environmentally friendly materials and meet food contact management requirements.

- top leader plastic

- China

- customized

- 1200 tons/month

- Information

- Video

Advantages of PETG sheets

It is an amorphous copolyester. As the CHDM in the copolymer increases, the melting point decreases, the glass transition temperature increases, and the crystallinity decreases. Finally, an amorphous polymer is formed, which can be quickly thermoformed or extruded and blown. The viscosity is better than that of acrylic (acrylic). Its products are highly transparent and have excellent impact resistance. It is especially suitable for forming thick-walled transparent products. Its processing and molding performance is excellent and it can be designed in any shape according to the designer's intention. Traditional extrusion can be used. Extrusion, injection molding, blow molding, and suction molding and other molding methods can be widely used in markets such as sheet metal sheets, high-performance shrink films, bottles, and special-shaped materials. At the same time, its secondary processing performance is excellent. Routine machining modifications are possible.

1Outstanding thermoforming performance

PETG sheets and boards are easy to produce products with complex shapes and large stretch ratios. Moreover, unlike PC boards and impact-modified acrylic, this board does not require pre-drying before thermoforming. Compared with PC board or acrylic, its molding cycle is short, the temperature is low, and the yield is higher.

Extruded sheets of PETG sheet are typically 15 to 20 times tougher than general-purpose acrylic and 5 to 10 times tougher than impact-modified acrylic. PETG sheet has sufficient endurance during processing, transportation and trial processes to help prevent cracking .

PETG sheets provide excellent weather resistance. It ensures the toughness of the product and prevents it from turning yellow. It contains UV absorbers that are coextruded into a protective layer that protects the board from the harmful effects of UV rays.

PETG sheets can be sawed, die-cut, drilled, punched, sheared, riveted, milled and cold-bent without breaking. Minor scratches on the surface can be removed with a heat gun. Flux bonding is also a routine operation. It is easier to process than general acrylic, impact-modified acrylic or PC sheets, and can be processed by flocking, electroplating, electrostatic processing, etc.

Within 15-20 days after received payment...more