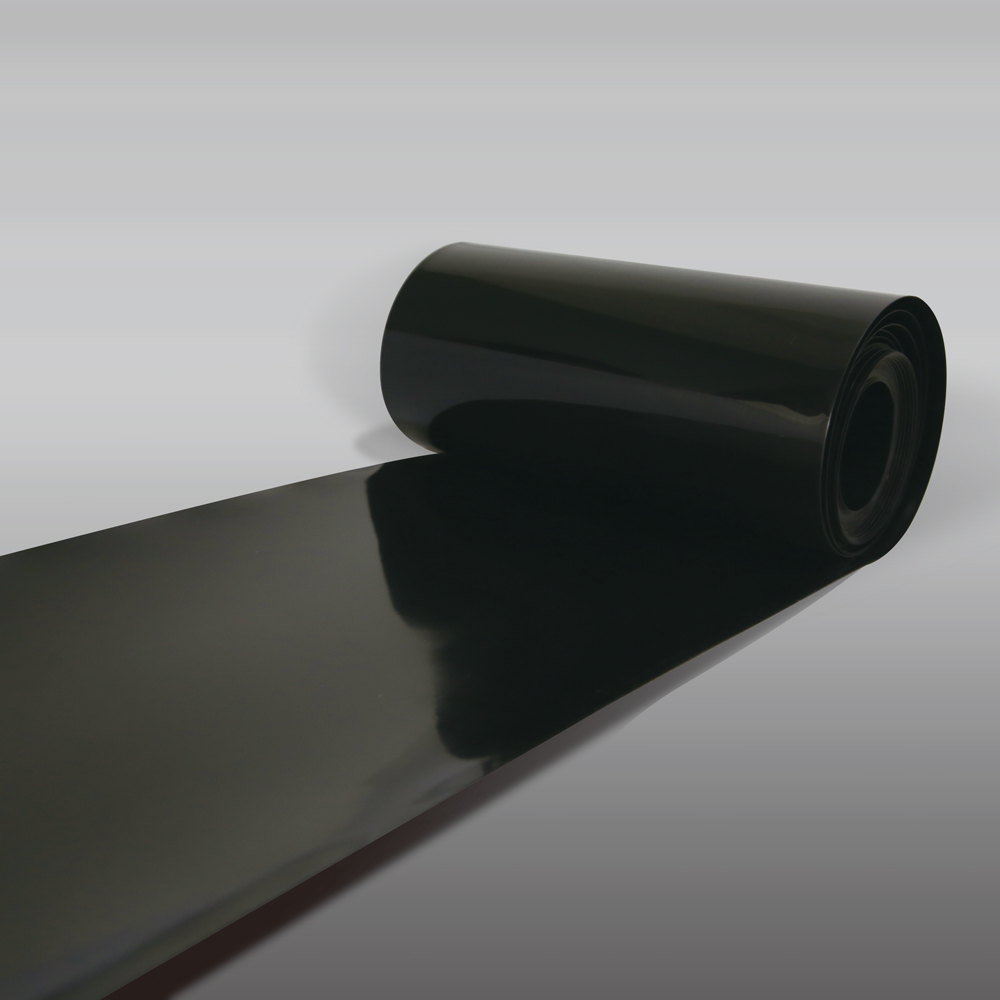

Polypropylene PP plastic sheet roll have made our lives more changes and improvements, and made our lives more convenient. PP products are common in our

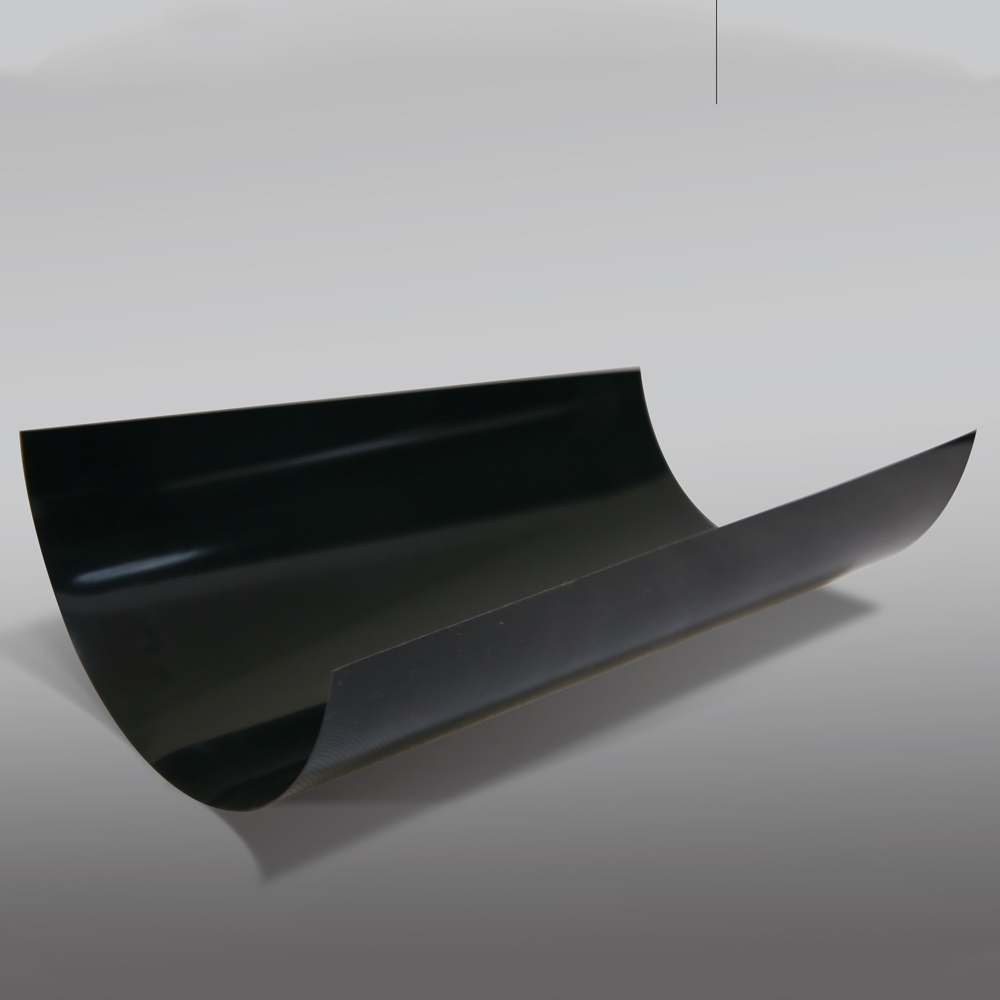

lives, and PP sheets are used in a wide range. There are many products made of it in our lives. It can be made into various

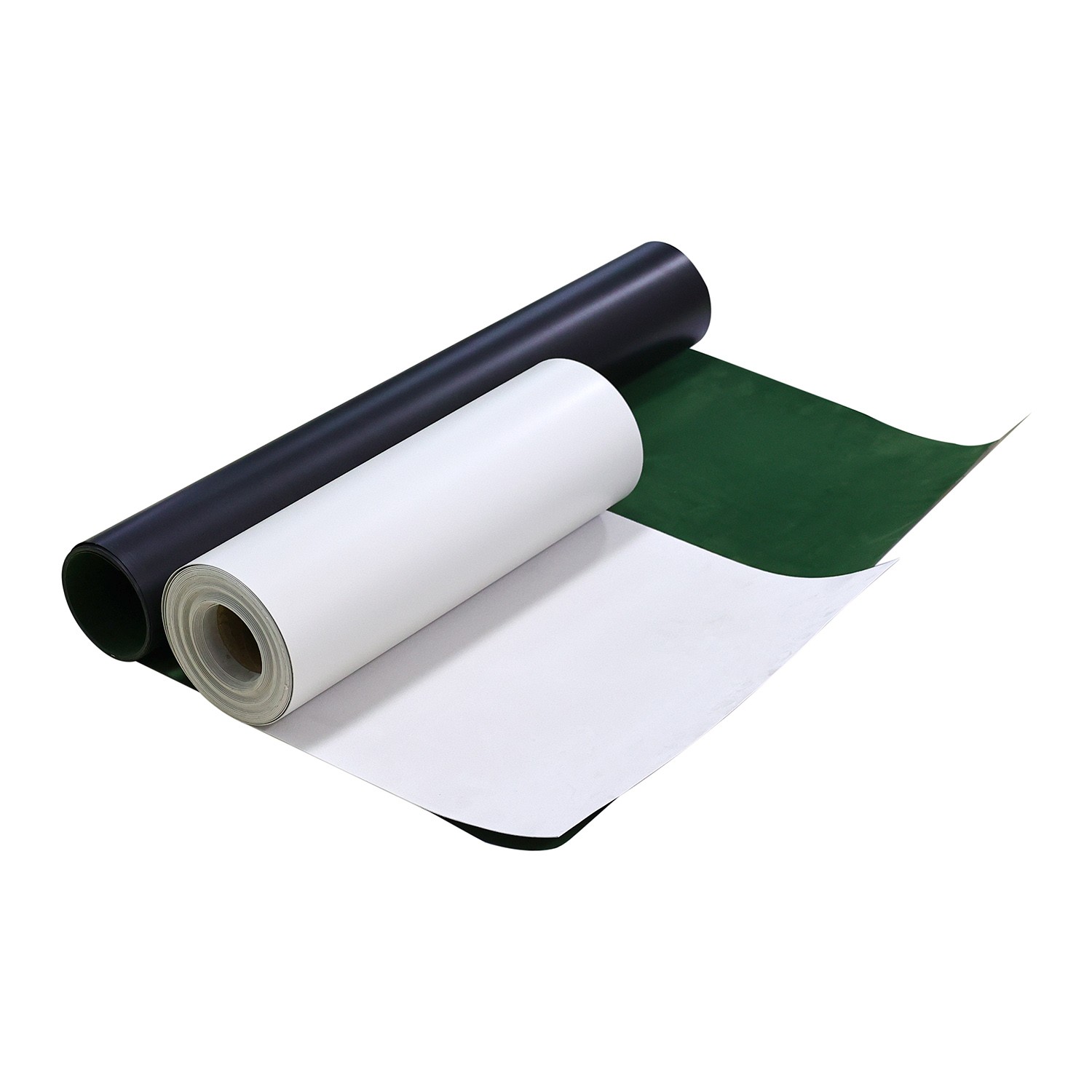

products through secondary processing such as thermoforming, which are mainly used for packaging of food, medicine, medical equipment, etc.

It can be used for food packaging such as processed jelly boxes, dairy packaging boxes, fast food boxes, cold drink containers, trays, microwave appliances, etc.; processed into blister can be used for the packaging of solid preparations

such as pharmaceutical tablets and capsules.