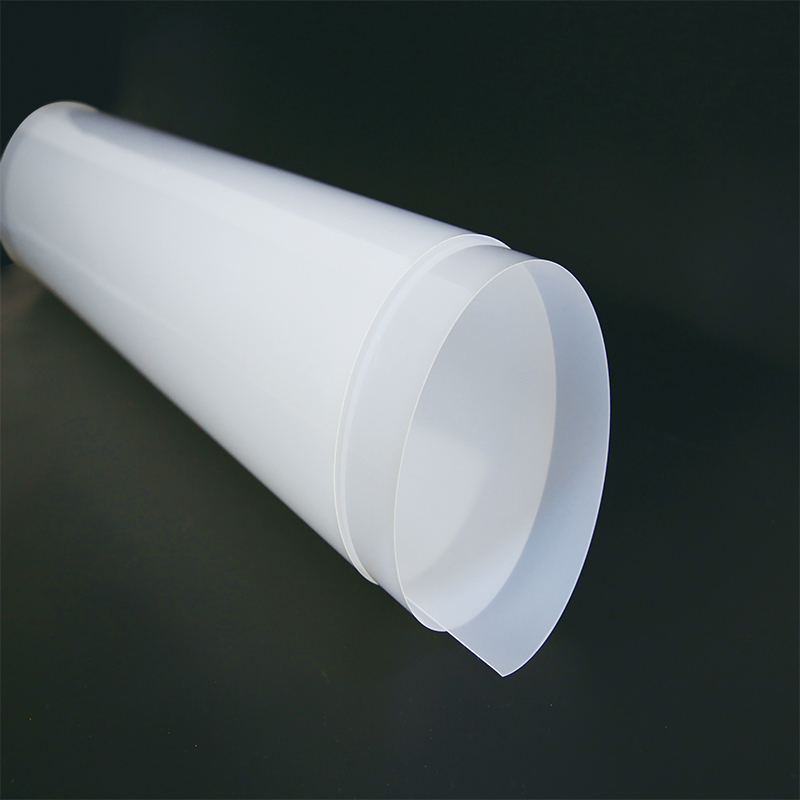

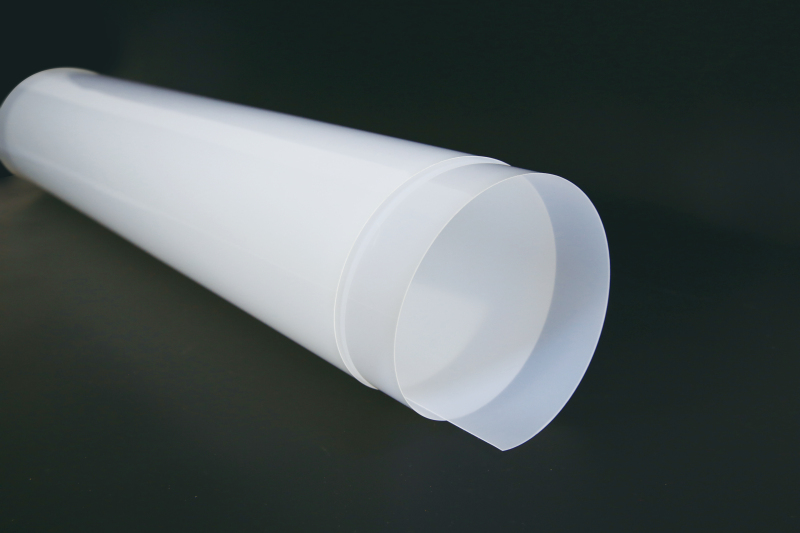

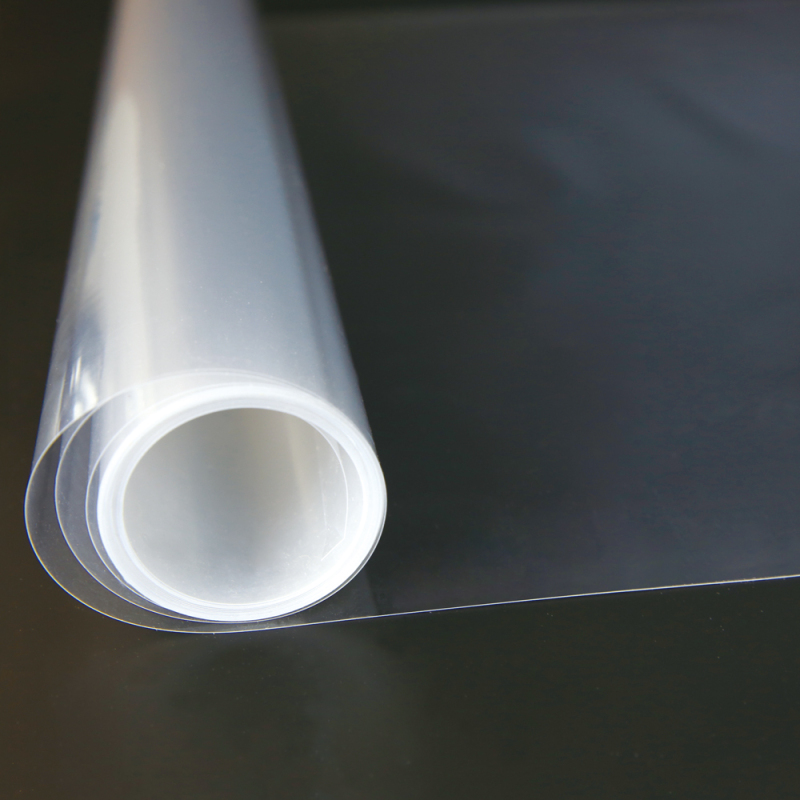

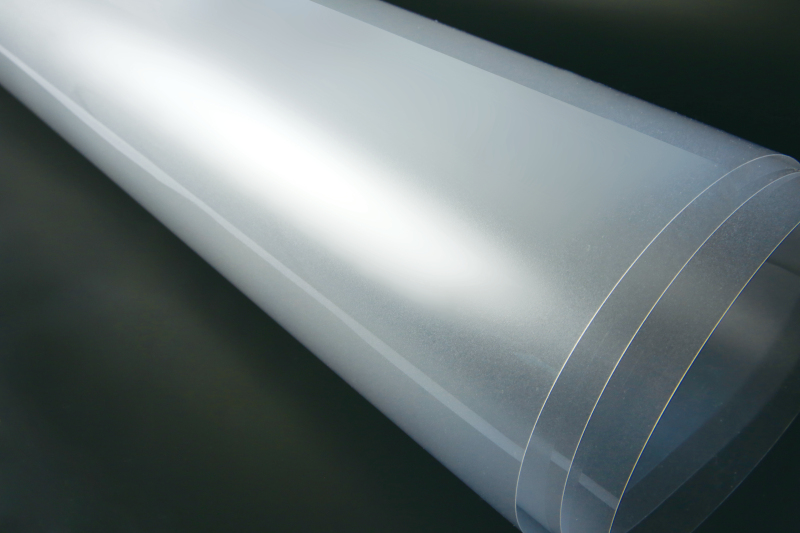

Environmental Color PP Polypropylene Rigid Film Sheet

Environmental Color PP Polypropylene Rigid Film Sheet.

food packaging roll pp sheet supplier Vacuum forming rigid pp polypropylene sheet

Product Features:

* Chemical resistance

Diluted alkalis and acids do not react with PP, which makes it an ideal container for this type of liquid.

* Elasticity and toughness

PP is elastic within a certain range of deflection, and will undergo plastic deformation without cracking in the early stage of deformation, so it is usually regarded as a “tough” material.

* Fatigue resistance

PP retains its shape after a lot of twisting and bending.

* Insulation

PP material has high resistance and is an insulating material.

* Transmittance

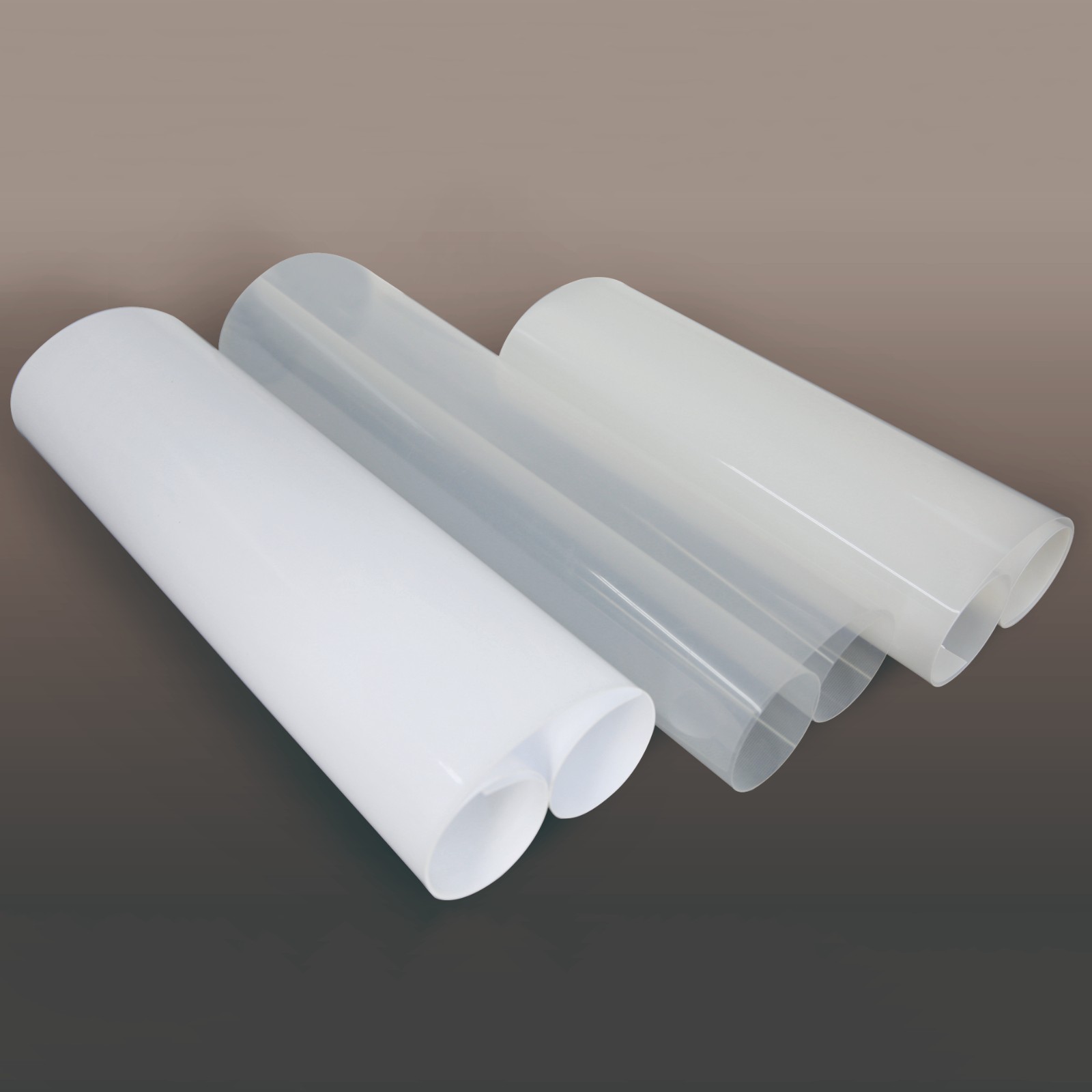

It can be made into a transparent color, but it is usually made into a natural opaque color with a certain color transmittance.

- top leader plastic

- china

- 12 days

- 5000 tons per month

- Information

- Video

Polypropylene Sheet Thermoforming Vacuum forming

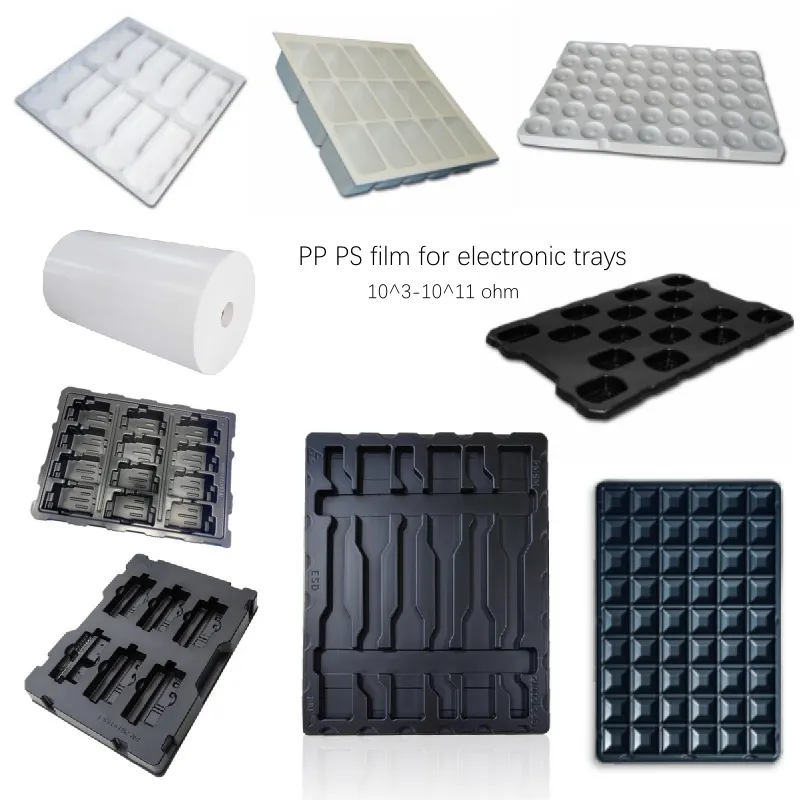

Polypropylene thermoforming is a lower-cost, efficient way to manufacture large plastic goods and components. Vacuum forming is the simplest method of polypropylene thermoforming. Once the plastic is heated and fitted around the custom tool, a high-powered vacuum removes air and draws the plastic more tightly against the tool. This method is best for plastic components that don’t require sharp edges, defined corners, or intricate details, such as food trays, electronic product trays, stationery packaging, cosmetic packaging, etc.

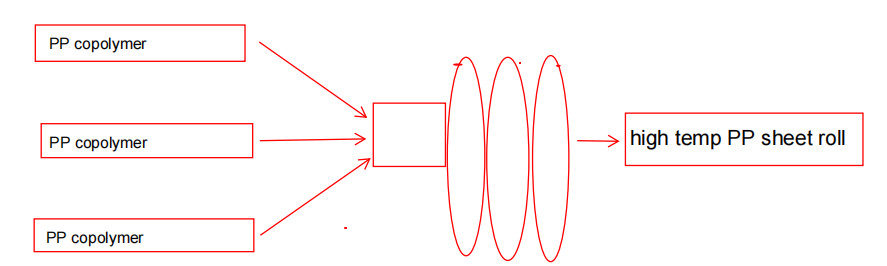

Polypropylene PP plastic sheet roll is a polymer formed by addition polymerization of propylene. It is a colorless, odorless, non-toxic, and translucent solid substance. Polypropylene particles are dyed, plasticized at high temperature and extruded into polystyrene sheets. PP sheets have chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties and good high wear-resistant processing properties. PP sheet has high transparency, good barrier properties, low density, non-toxic and hygienic, and can be recycled. It will not produce toxic and harmful gases when heated or burned, does not harm human health, and does not corrode equipment. It is a new type green environmental protection packaging materials.

Physical and Chemical Properties

Structure of PP material:

Applications of Polypropylene PP plastic sheet roll

Polypropylene PP plastic sheet roll have made our lives more changes and improvements, and made our lives more convenient. PP products are common in our

lives, and PP sheets are used in a wide range. There are many products made of it in our lives. It can be made into variousproducts through secondary processing such as thermoforming, which are mainly used for packaging of food, medicine, medical equipment, etc.

such as pharmaceutical tablets and capsules.

Within 15-20 days after received payment...more