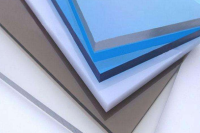

TL-PC-211 Plastic PC sheet/PC solid board sheet/PC decorative board

One major reason why PVC boards are preferred in hardware packaging is that they are very hard-wearing. It has very high resistance to impact, chemicals, moisture, and UV. PVC protects the packaged products from a wide range of external influences that could lead to damage. This is very vital for items of hardware nature since they are, in most cases, exposed to various severe conditions, whether during storage, shipment, or on store shelves. The rigidity of the PVC boards provides an impenetrable barrier against dents, scratches, and other forms of physical damage, preventing them from reaching the contents. Hence, they are safe and secured.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

Title: Versatility in Hardware Packaging by PVC Boards

Durability, protection, and cost are the three major elements of hardware packaging, and this is what matters in the selection of materials. Over the past few years, there has been a remarkable increase in the use of polyvinyl chloride boards as materials for hardware packaging. Be it in terms of strength or flexibility and low costs, PVC boards have maintained a leading position that is hard to reach. Be it used to protect tools, electronic elements, or other hardware products, PVC boards will do an excellent job at meeting the demanding requirements in this line of business.

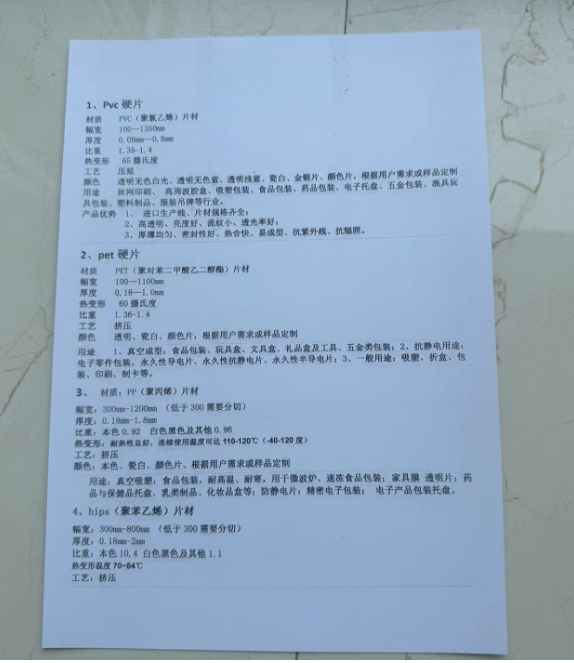

Why PVC Boards for Hardware Packaging?

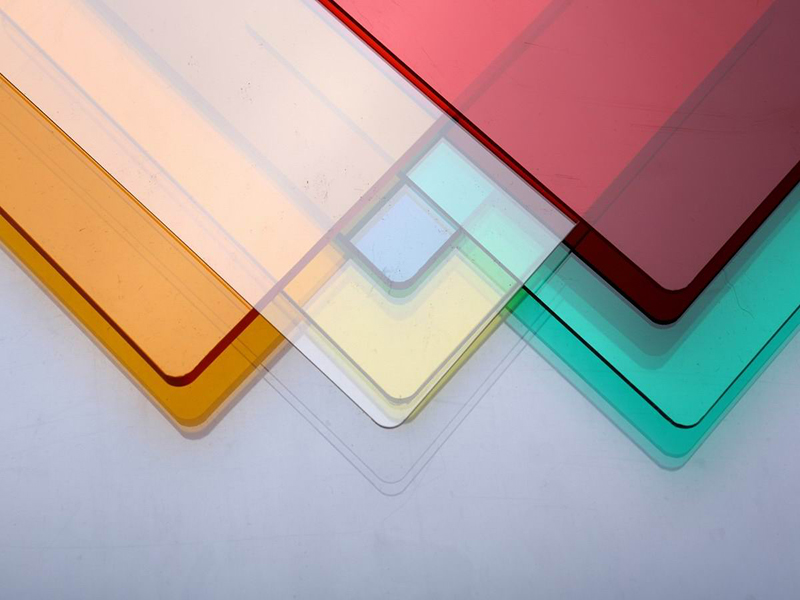

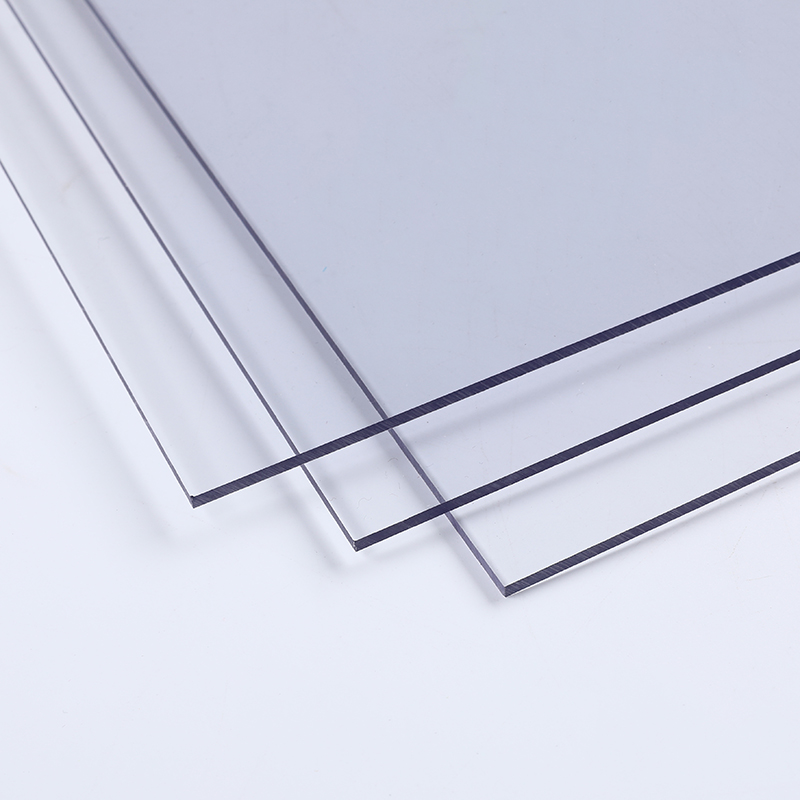

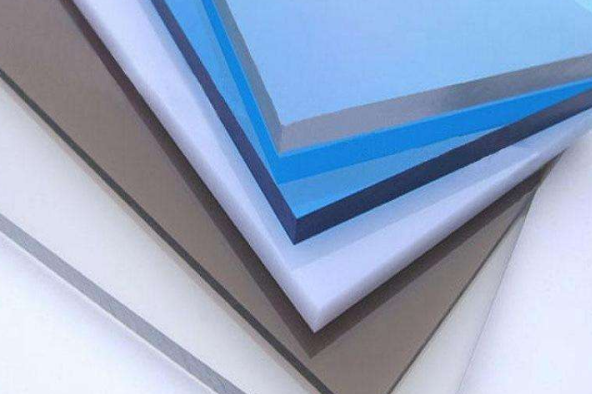

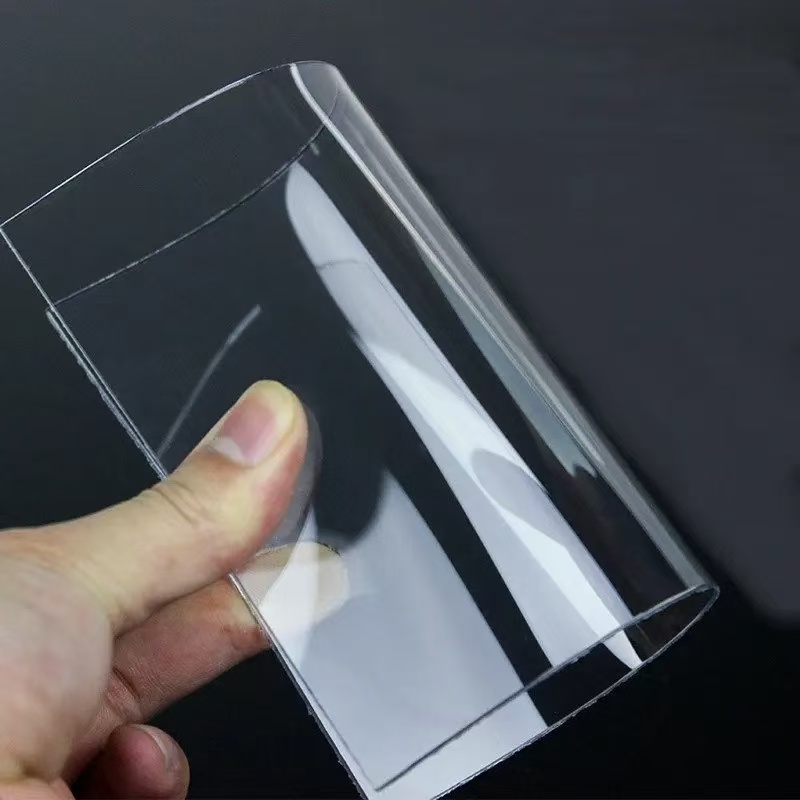

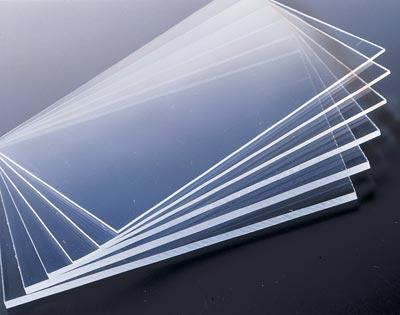

PVC boards are plastic sheeting made from a strong and rigid material called polyvinyl chloride, able to stand the forces of nature. Such boards possess a lightweight property but a remarkable strength unto themselves and can thus be used for any hardware items of great mass or fragile pieces of hardware equipment needing protection during storage and transportation. In comparison to traditional materials for packaging, PVC boards offer a high degree of customization, thereby allowing manufacturers to make packages of the right size, shape, and weight accorded to a product.

Durability and Protection:

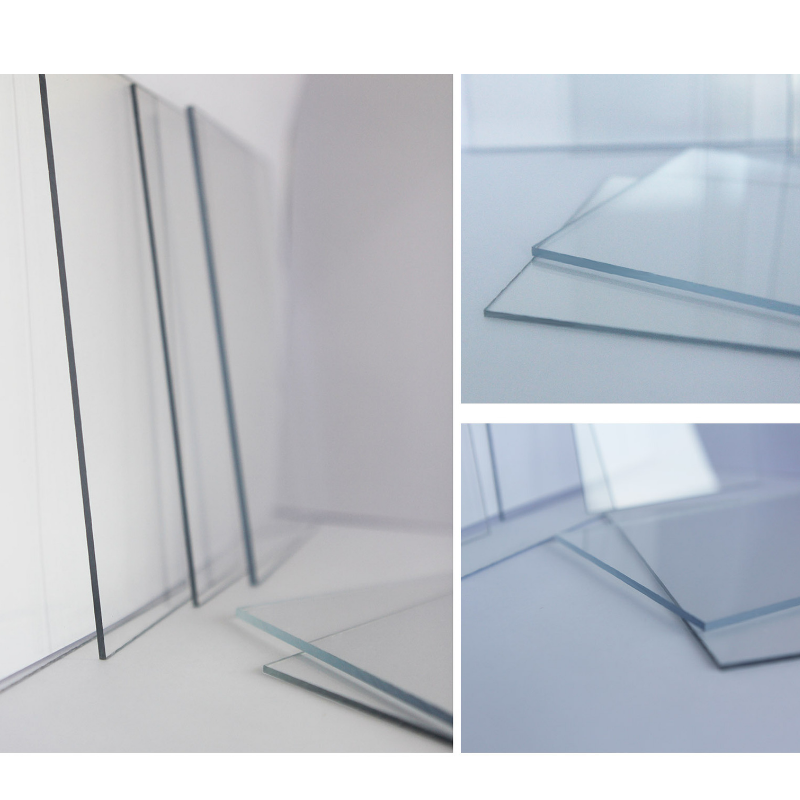

One major reason why PVC boards are preferred in hardware packaging is that they are very hard-wearing. It has very high resistance to impact, chemicals, moisture, and UV. PVC protects the packaged products from a wide range of external influences that could lead to damage. This is very vital for items of hardware nature since they are, in most cases, exposed to various severe conditions, whether during storage, shipment, or on store shelves. The rigidity of the PVC boards provides an impenetrable barrier against dents, scratches, and other forms of physical damage, preventing them from reaching the contents. Hence, they are safe and secured.

Design Flexibility:

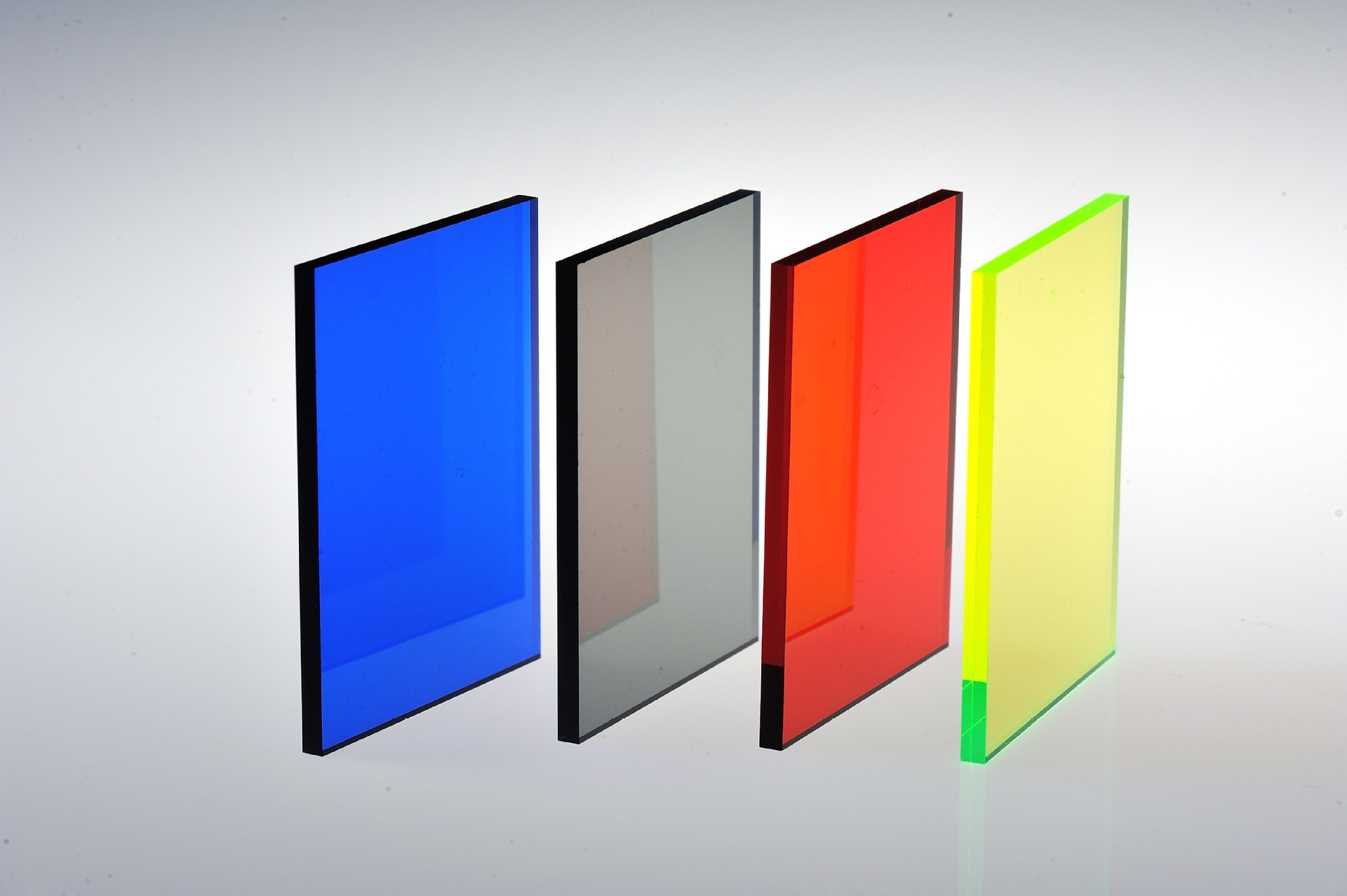

The PVC boards are highly flexible in design, something that is very critical in hardware packaging, as they need to come in various shapes and dimensions. The boards are easily cut, shaped, and formed for specific products to create a close fit that limits movement and possible damage during transport. In addition, high-quality graphics, logos, and product information can be printed on PVC boards, thus enhancing the look of a package and communicating useful information to the target consumers.

Cost-Effective Solution:

The other major benefit associated with the use of PVC boards in hardware packing is cost effectiveness. As compared to other materials for packaging, like metal and wood, PVC boards come at a cheaper price for almost the same amount of protection. Their lightweight nature also makes shipment costs minimal as lighter packages require less to deliver. Further, it provides long-term savings since the PVC boards are strong enough to be employed more than once, thereby offering long-term cost savings to the manufacturers and distributors.

Environmental Considerations:

Though PVC belongs to the category of plastics, innovative manufacturing has helped in recent times to create PVC boards in an environmentally friendly way. Some options for PVC are recyclable, which helps companies reduce their impact on the environment. The longevity of PVC boards further supports the concept of sustainability as they do not need to be replaced often, which means that less waste will be created over time.

Applications in Hardware Packaging:

From toolkits and cases of electronic components to protective covers for industrial equipment, PVC boards find their place in a whole range of hardware packaging applications. Their versatility can help them be employed in small-scale packaging for each tool or large-scale applications as protective covers at pallet sizes. In each case, properties in PVC boards ensure that the hardware is preserved, smartly presented, and easily handled.

Conclusion:

The PVC board has grown to become an indispensable material in the hardware packaging industry by offering this blend of durability, customizability, and cost-effectiveness. With increasing demands for better and more protective packaging, the boards are likely to take the lead in ensuring that hardware products reach their destinations safely and perfectly. For manufacturers and distributors in dire need of a solution that will work out quite reliable, PVC boards play their role as practical and efficient on all fronts when it comes to packaging.

Within 15-20 days after received payment...more