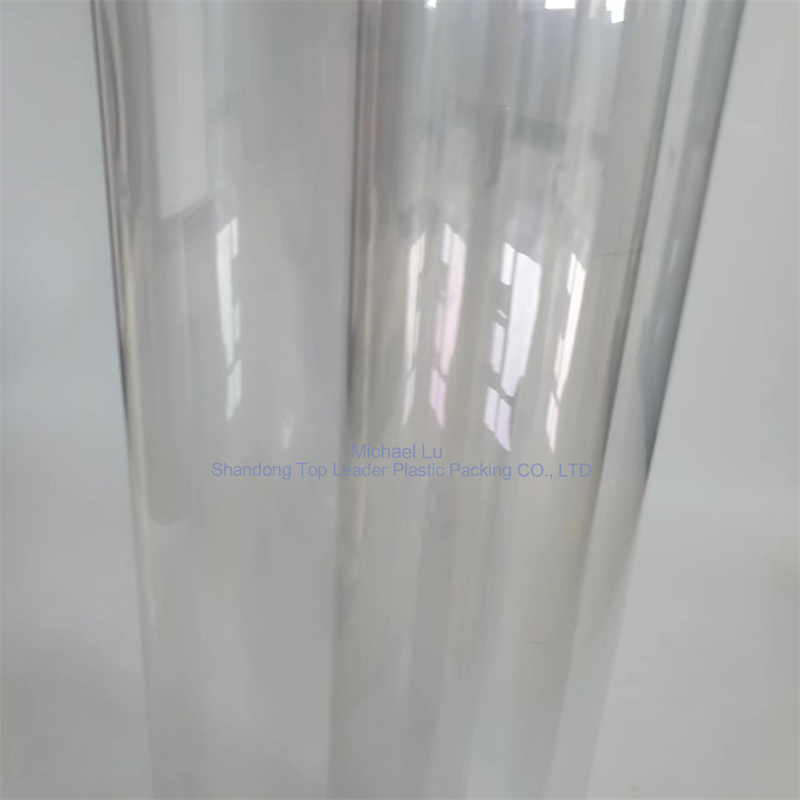

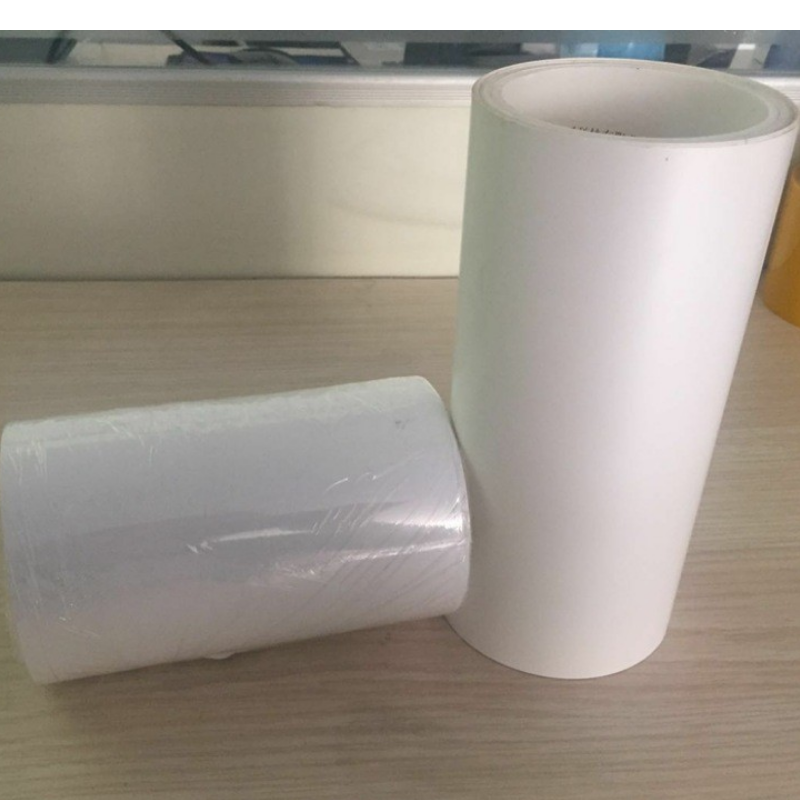

PET Sheet for Thermoforming Electronic Product Trays

Introduction:

The use of PET (Polyethylene Terephthalate) sheet in the manufacturing of electronic product trays is a testament to the material’s versatility and performance in safeguarding delicate components. These trays are designed using thermoforming, a process that involves heating a plastic sheet and forming it over a mold.

- top leader plastic

- China

- customized

- 1600 tons/month

- Information

- Video

PET Sheet for Thermoforming Electronic Product Trays

1. Conductive Properties: PET can be engineered with conductive materials, making it suitable for electronic trays that require static dissipation

2. Anti-Static: Through specific treatments or additives, PET sheets can have anti-static properties, reducing the risk of electrostatic discharge, which can damage electronic components.

3. Durability: PET sheets have excellent resistance to impact, which helps protect the content during handling and transport.

4. Chemical Resistance: PET sheets are resistant to many chemicals, including some acids and oils, making them suitable for various industrial applications.

5. Recyclability: PET is a recyclable material, which aligns with global efforts towards sustainability and reducing environmental impact.

Applications:

- Electronic component trays for storage and transportation

- ESD-safe trays for sensitive electronic assemblies

- Carrier trays for electronic components during the manufacturing process

Within 15-20 days after received payment...more