Food Grade PETG Thermoplastic Films for Packaging

PET film has good printability, excellent dimensional stability, good surface and barrier properties.

Widely use for packaging

PET film is used successfully in a wide range of applications, due to its excellent combination of

optical,physical, mechanical, thermal, and chemical properties, as well as its unique versatility.

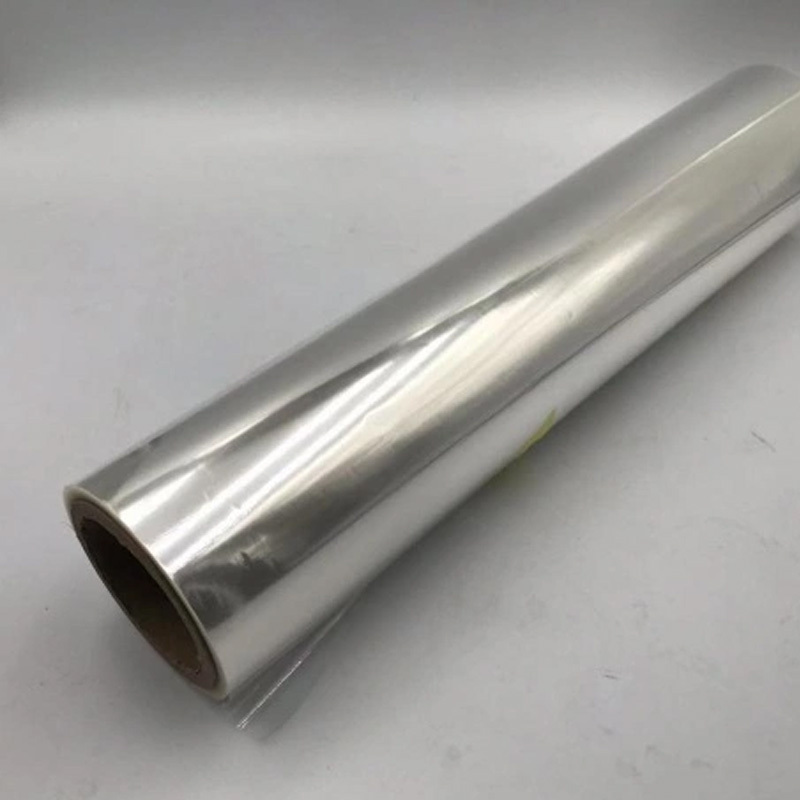

1.It has excellent transparency and finish, and the display effect is good.Factory supply Hot sell transparent

vacuum forming plastic sheets

2. Excellent surface decoration performance, can be printed without surface treatment, easy to press patterns,

easy metal treatment (vacuum metal coating)

3. It has good mechanical strength.

4. The barrier performance for oxygen and steam is good.

5. Good chemical resistance, can withstand the erosion of a variety of chemicals.

6. Non-toxic, reliable hygienic performance, can be used for food, drugs and medical equipment packaging,

and Y-ray can sterilize the packed articles.

7. Pet sheet is considered to be an ideal packaging material to meet the requirements of (ROSH) environmental

protection.

- Information

- Video

Basic Info.

Product Description

About PET sheet

PET film has good printability, excellent dimensional stability, good surface and barrier properties.

Widely use for packaging

PET film is used successfully in a wide range of applications, due to its excellent combination of

optical,physical, mechanical, thermal, and chemical properties, as well as its unique versatility.

1.It has excellent transparency and finish, and the display effect is good.Factory supply Hot sell transparent

vacuum forming plastic sheets

2. Excellent surface decoration performance, can be printed without surface treatment, easy to press patterns,

easy metal treatment (vacuum metal coating)

3. It has good mechanical strength.

4. The barrier performance for oxygen and steam is good.

5. Good chemical resistance, can withstand the erosion of a variety of chemicals.

6. Non-toxic, reliable hygienic performance, can be used for food, drugs and medical equipment packaging,

and Y-ray can sterilize the packed articles.

7. Pet sheet is considered to be an ideal packaging material to meet the requirements of (ROSH) environmental

protection.

| Product Name | packing material stretch film metallized film plastic sheet 0.3mm Clear Transparent polyester Pet Apet R-PET recycling film for food tays and Folding box |

| Application | Packaging |

| Thickness | 0.25mm,0.35mm or customized |

| Width | Slitted:50-300 mm; Jumbo Roll:500-1600mm |

| Inner Core Diameter | 76mm |

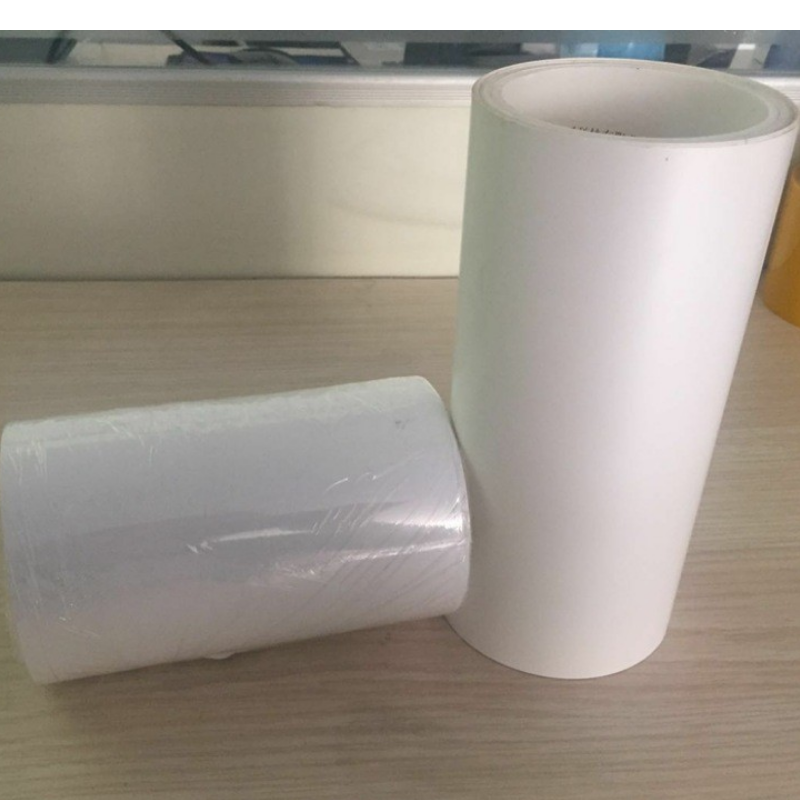

| Color | Transparent, Glass clear,Clear with blue tint, Amber, Orange, White, Blue, Brown, Pink, Green, Yellow or Customized |

| Surface | Bright, Clean and Glossy |

| Delivery time | 7-10 days |

| Advantage | 1.High transparency, bright surface luminance. 2.Smooth surface, uniform thickness. 3.Few hydrological veins, few crystal points. 4.No smell and non-toxic. 5.Anti-cold 6.Can easily be thermoformed, printed, and folded 7.All colors transparency |

| Packaging | In pallet,Paper Carton etc. |

What's the difference between a hot laminating film and a cold laminating film?

The adhesive on a "hot" laminating film activates when the printed graphic is run through a hot-roll laminator at temperatures between 210 and 240 degrees. Because these high levels of heat can damage some types of inkjet graphics, "low-melt" or "heat-assist" films are also used. "Low melt" films have heat-activated adhesives that can applied at 185 to 195 degrees. "Heat assist" films have pressure-sensitive adhesives (PSAs) and liners and are applied with hot-roll laminators at 185 to 195 degrees.

"Cold" laminating films have a more aggressive adhesive that can be applied with pressure, instead of heat. A release liner protects the adhesive until it ready to applied, typically on a cold-roll laminator. Cold laminating films typically cost more than hot laminating films, but they can be applied using less costly, easier-to-operate non-heated laminators.

Cold roll laminators are also used for laying down adhesive films in the sign-making industry, for example mounting a large print onto a board. A practiced operator can apply a large adhesive sheet in a fraction of the time it takes to do so by hand.