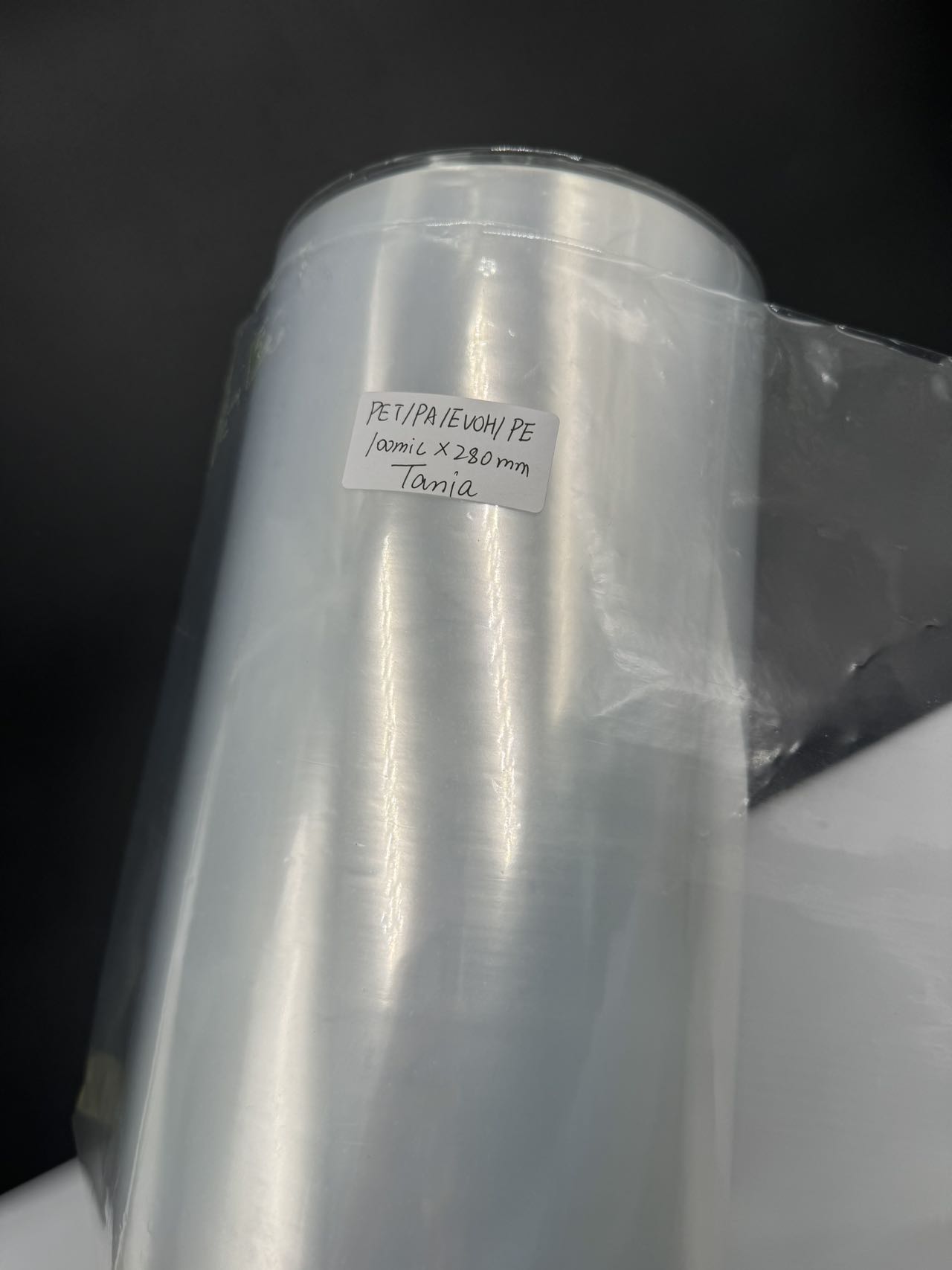

TL-PET/PA/EVOH/PA-128 The Versatile Applications of PET/PA/EVOH/PE Composite Membrane in Pharmaceutical and Food Packaging

1. Material Composition

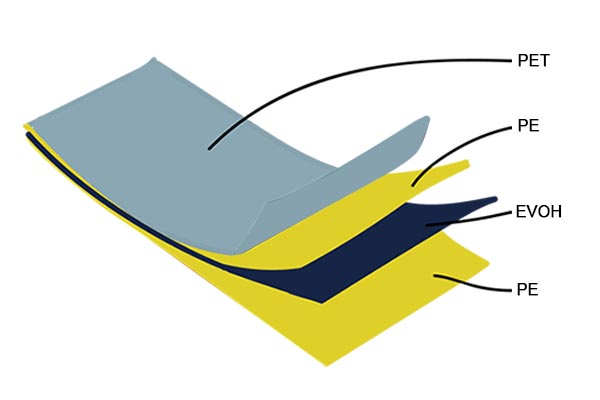

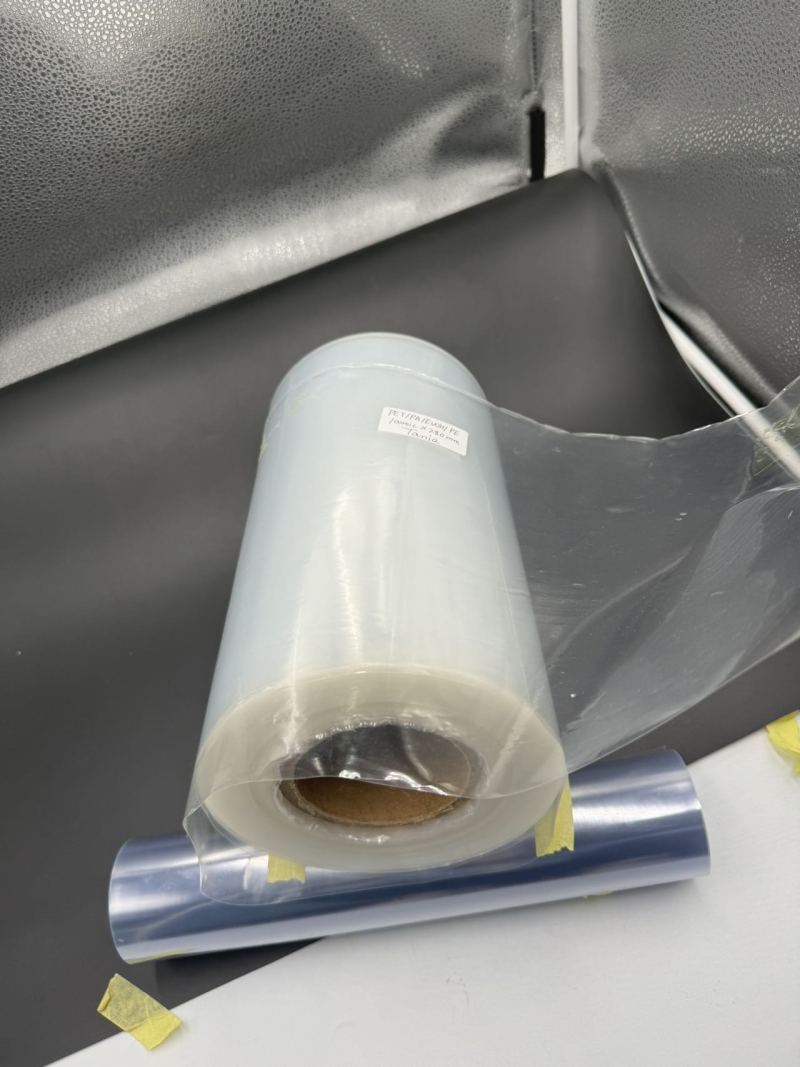

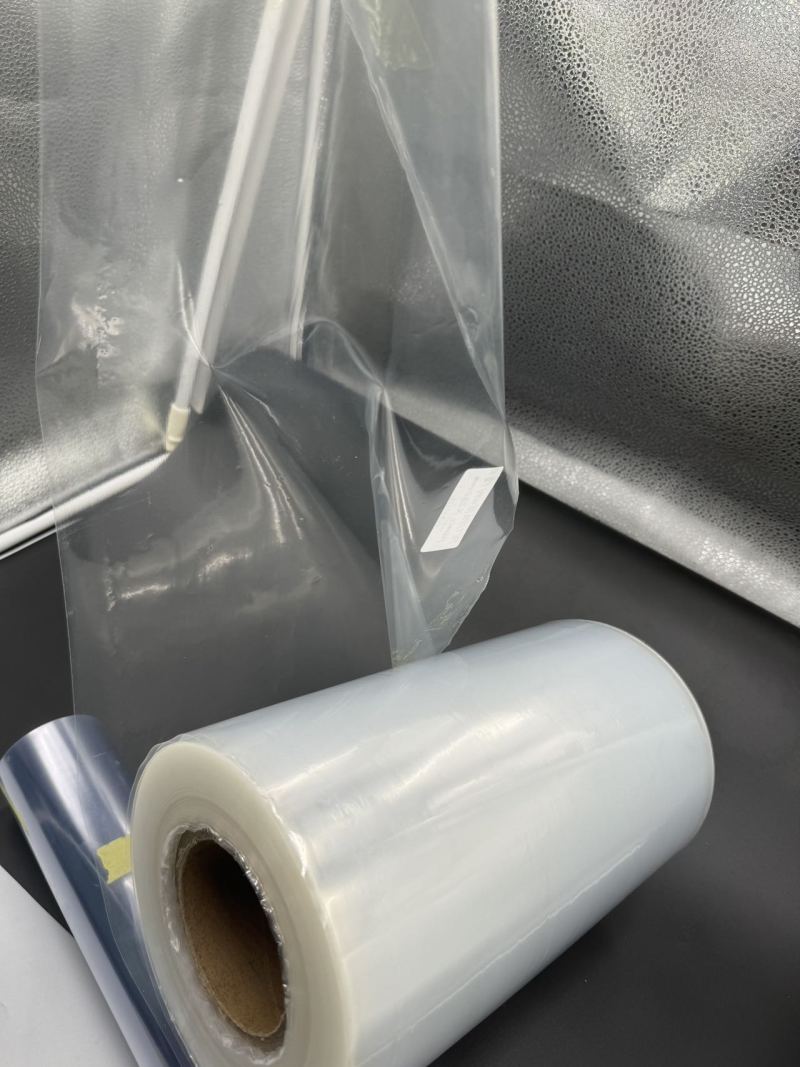

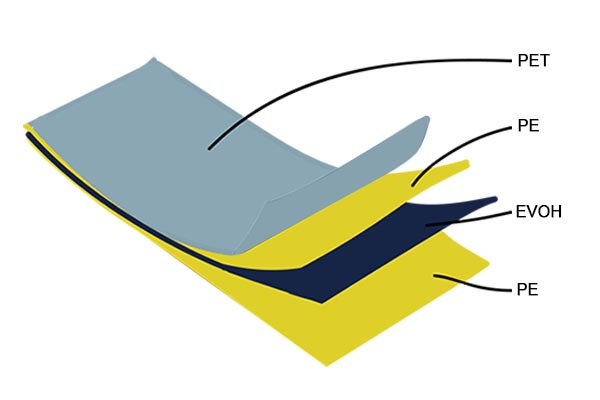

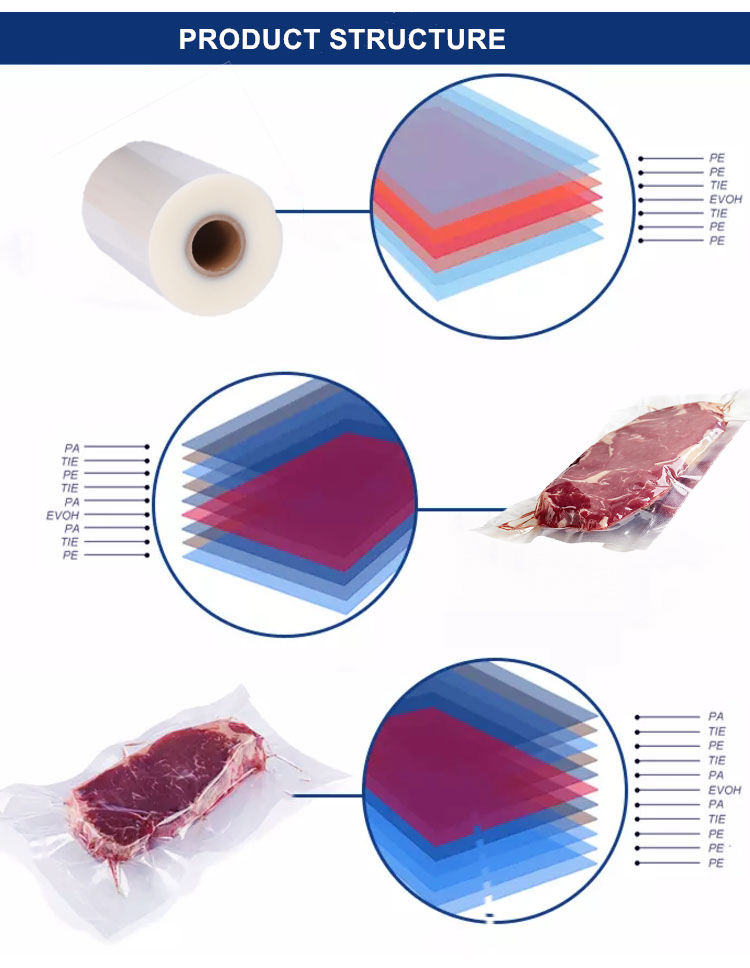

The PET/PA/EVOH/PE composite membrane is made up of several layers of different materials. The outermost layer is usually made of polyethylene terephthalate (PET), which provides strength and durability. The next layer is polyamide (PA), which offers excellent barrier properties against moisture and gases. The ethylene vinyl alcohol (EVOH) layer is known for its exceptional oxygen barrier properties, while the innermost layer of polyethylene (PE) provides a heat-sealable surface.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

The Versatile Applications of PET/PA/EVOH/PE Composite Membrane in Pharmaceutical and Food Packaging

Introduction

In the modern world, packaging plays a crucial role in ensuring the safety, quality, and shelf life of products. When it comes to pharmaceutical and food packaging, the requirements are even more stringent. The PET/PA/EVOH/PE composite membrane has emerged as a highly effective packaging solution, offering excellent properties such as freshness preservation, oxygen barrier, and heat sealability. In this article, we will explore the various applications of this composite membrane in pharmaceutical and food packaging.

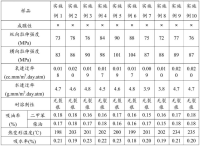

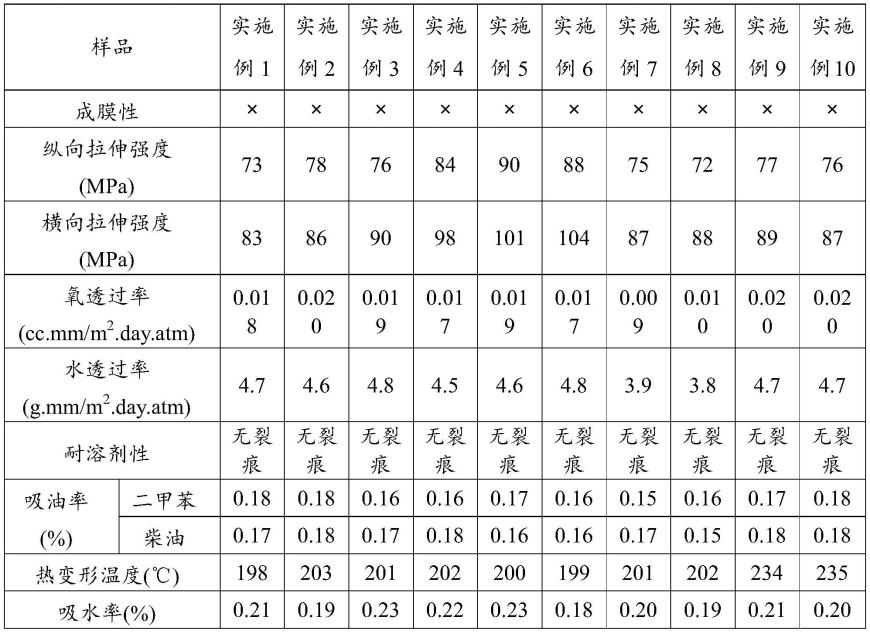

I. Properties of PET/PA/EVOH/PE Composite Membrane

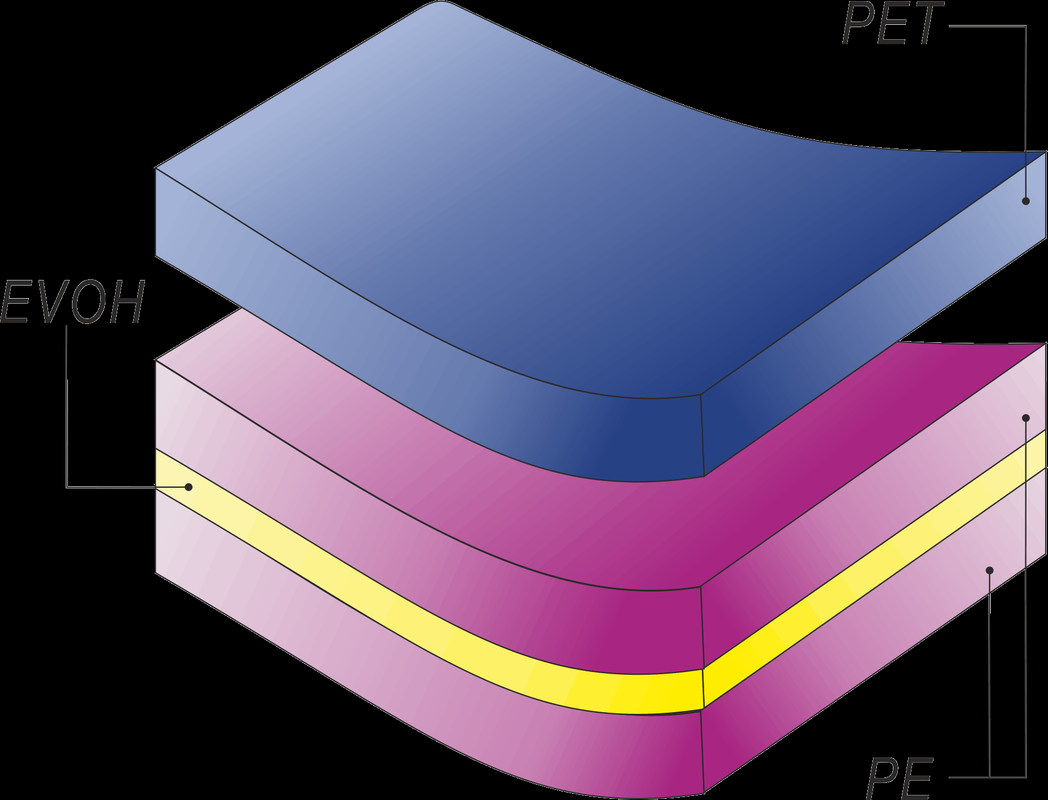

1. Material Composition

The PET/PA/EVOH/PE composite membrane is made up of several layers of different materials. The outermost layer is usually made of polyethylene terephthalate (PET), which provides strength and durability. The next layer is polyamide (PA), which offers excellent barrier properties against moisture and gases. The ethylene vinyl alcohol (EVOH) layer is known for its exceptional oxygen barrier properties, while the innermost layer of polyethylene (PE) provides a heat-sealable surface.

2. Freshness Preservation

One of the key advantages of the PET/PA/EVOH/PE composite membrane is its ability to preserve the freshness of packaged products. The combination of different materials in the composite membrane creates a barrier that prevents the entry of oxygen, moisture, and other contaminants. This helps to extend the shelf life of pharmaceutical and food products, ensuring that they remain safe and effective for a longer period.

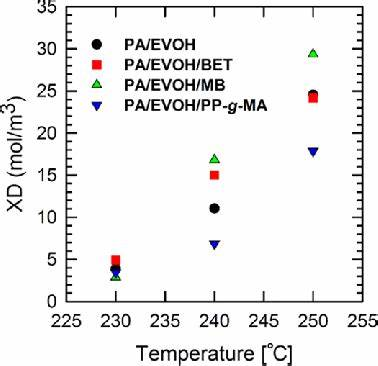

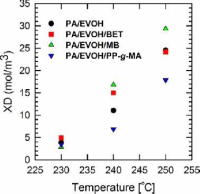

3. Oxygen Barrier

The EVOH layer in the composite membrane is particularly effective in blocking oxygen. Oxygen can cause degradation and spoilage of food and pharmaceutical products, reducing their quality and shelf life. The high oxygen barrier properties of the EVOH layer help to protect the packaged products from oxidation, ensuring their stability and integrity.

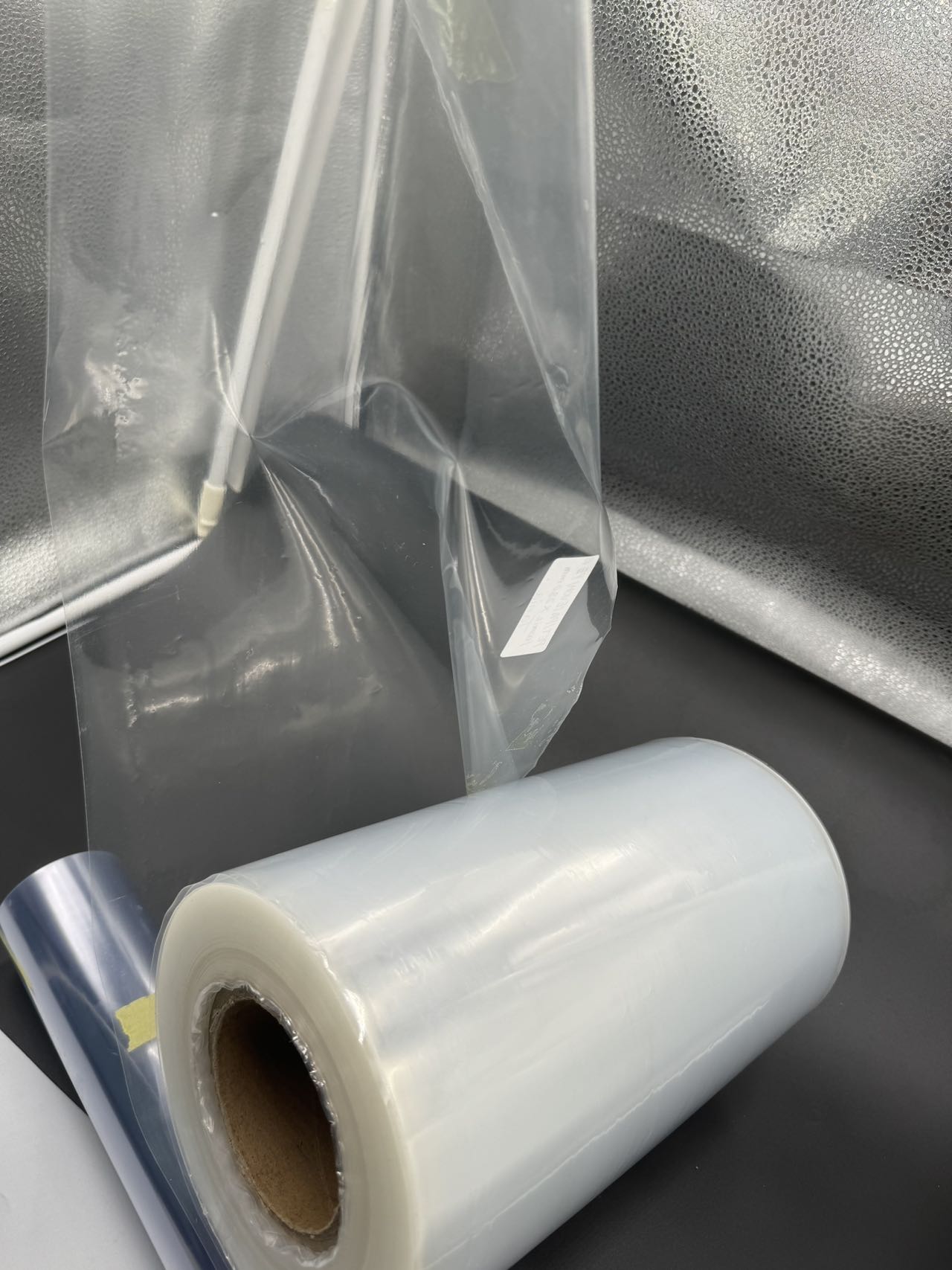

4. Heat Sealability

The PE layer on the inside of the composite membrane provides a heat-sealable surface, making it easy to seal the packaging. Heat sealing is a common packaging method that ensures a tight and secure seal, preventing the entry of air and contaminants. The heat sealability of the PET/PA/EVOH/PE composite membrane makes it suitable for various packaging applications, including pouches, bags, and blister packs.

II. Applications in Pharmaceutical Packaging

1. Tablets and Capsules

The PET/PA/EVOH/PE composite membrane is widely used for packaging tablets and capsules. The oxygen barrier properties of the membrane help to protect the active ingredients in the medications from degradation, ensuring their potency and effectiveness. The moisture barrier also prevents the tablets and capsules from absorbing moisture, which can cause them to stick together or lose their shape.

For example, blister packs made of the composite membrane are commonly used for packaging individual tablets or capsules. The blisters provide a protective barrier and allow for easy dispensing of the medications. The heat sealability of the membrane ensures that the blisters are tightly sealed, protecting the contents from moisture and oxygen.

2. Powders and Granules

Pharmaceutical powders and granules also require effective packaging to maintain their quality and stability. The PET/PA/EVOH/PE composite membrane is suitable for packaging these products as it provides a barrier against moisture and oxygen. The membrane can be used to make pouches or bags that are easy to fill and seal.

In addition, the composite membrane can be printed with important information such as product name, dosage, and expiration date. This helps to ensure proper identification and usage of the pharmaceutical products.

3. Liquid Pharmaceuticals

For liquid pharmaceuticals, the composite membrane can be used to make bottles or pouches with excellent barrier properties. The oxygen and moisture barrier help to prevent the degradation of the liquid medications, ensuring their quality and safety. The heat sealability of the membrane allows for easy sealing of the packaging, preventing leakage.

III. Applications in Food Packaging

1. Snack Foods

Snack foods such as chips, nuts, and cookies are highly susceptible to oxidation and moisture absorption. The PET/PA/EVOH/PE composite membrane provides an effective barrier against these factors, helping to maintain the freshness and crunchiness of the snacks. The membrane can be used to make pouches or bags that are easy to open and close, providing convenience for consumers.

For example, resealable pouches made of the composite membrane are popular for packaging snacks. The pouches can be opened and closed multiple times, keeping the snacks fresh for a longer period. The oxygen barrier properties of the membrane prevent the snacks from becoming stale, while the moisture barrier prevents them from becoming soft.

2. Frozen Foods

Frozen foods require packaging that can withstand low temperatures and protect the products from freezer burn. The PET/PA/EVOH/PE composite membrane is suitable for packaging frozen foods as it provides a barrier against moisture and oxygen. The membrane can be used to make bags or pouches that are strong and durable, ensuring that the frozen foods remain in good condition.

In addition, the composite membrane can be printed with cooking instructions and nutritional information, providing convenience for consumers.

3. Meat and Poultry

Meat and poultry products are highly perishable and require packaging that can extend their shelf life. The PET/PA/EVOH/PE composite membrane offers excellent oxygen and moisture barrier properties, helping to prevent spoilage and bacterial growth. The membrane can be used to make vacuum-sealed bags or trays that keep the meat and poultry fresh for a longer period.

For example, vacuum-sealed packaging made of the composite membrane is commonly used for packaging fresh meat and poultry. The vacuum-sealed environment helps to slow down the oxidation process and prevent the growth of bacteria. The oxygen barrier properties of the membrane ensure that the meat and poultry remain red and fresh-looking.

IV. Advantages of PET/PA/EVOH/PE Composite Membrane over Other Packaging Materials

1. Superior Barrier Properties

Compared to other packaging materials, the PET/PA/EVOH/PE composite membrane offers superior barrier properties against oxygen, moisture, and other contaminants. This helps to extend the shelf life of packaged products and maintain their quality and safety.

2. Heat Sealability

The heat sealability of the composite membrane makes it easy to seal the packaging, ensuring a tight and secure seal. This helps to prevent the entry of air and contaminants, protecting the packaged products.

3. Durability

The composite membrane is made of strong and durable materials, making it suitable for various packaging applications. It can withstand handling, transportation, and storage without tearing or puncturing.

4. Printability

The surface of the composite membrane can be printed with high-quality graphics and text, providing an attractive packaging solution. This helps to enhance the brand image and marketability of the packaged products.

V. Conclusion

The PET/PA/EVOH/PE composite membrane is a highly versatile packaging material with excellent properties for pharmaceutical and food packaging. Its ability to preserve freshness, provide oxygen barrier, and offer heat sealability makes it an ideal choice for a wide range of applications. As the demand for high-quality packaging continues to grow, the PET/PA/EVOH/PE composite membrane is likely to play an even more important role in ensuring the safety and quality of pharmaceutical and food products.

Within 15-20 days after received payment...more