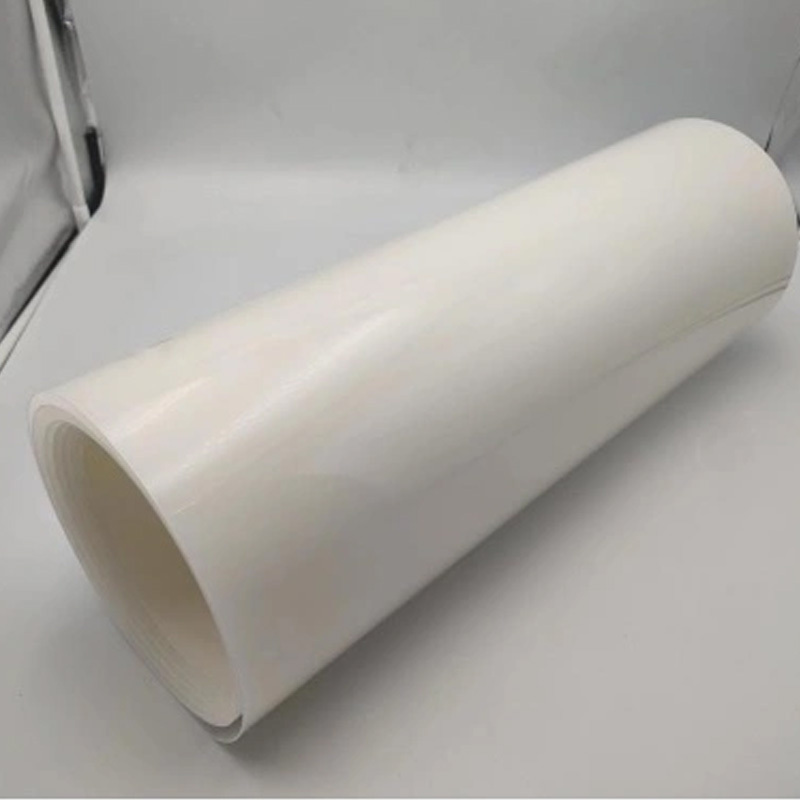

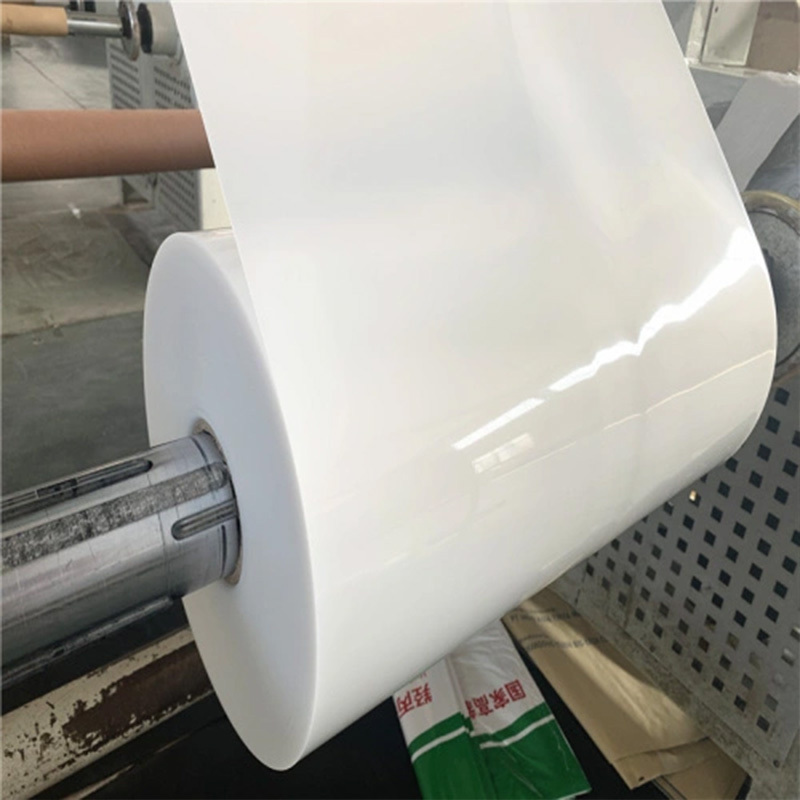

Polypropylene Rigid PP Plastic Film Thermoforming

Polypropylene (PP) film is a standard plastic material frequently used for producing packs. The material is characterised by its good barrier properties, heat resistance, and stability, and it is suitable for producing packs for medical and pharmaceutical products.

- Information

Basic Info.

Use

Packaging Products

Size

Width 50mm - 2300mm

MOQ

500kgs

Grade

Food Garde AA

Surface

High Gloss or Matte

Quality

High Quality.SGS Inspection

Description

Printed Food Packaging Film

Payment

30%Tt Advance

Key Words

Clear Plastic PVC Sheet

Transport Package

Sea Transportation

Specification

PVC film

Trademark

Shandong Top Leader Plastic Packing Co., Ltd

Origin

Shangdong

HS Code

3920430090

Production Capacity

5000 Metric Ton/Metric Tons Per Month

Product Description

Product Description

Regulatory compliance (FDA & EU) High Barrier PP EVOH Sheet Plastic Roll for Thermoformed Yogurt Cup with Shelf-life Performance 6 months to 2 years

Regulatory compliance (FDA & EU) High Barrier PP EVOH Sheet Plastic Roll for Thermoformed Yogurt Cup with Shelf-life Performance 6 months to 2 years

Product Name | PP/EVOH/PP conductive plastic sheet in roll |

Material | Plastic |

Color | Any color |

Standard | SGS, ROHS |

Grade | Medical grade, food grade and conductive grade |

Width | 300~900mm |

Thickness | 0.3~1.5mm |

Used | Mainly applied to the packaging of food, medicine, electronics, cosmetics&gifts. |

Polypropylene (PP) film is a standard plastic material frequently used for producing packs. The material is characterised by its good barrier properties, heat resistance, and stability, and it is suitable for producing packs for medical and pharmaceutical products. However, running this material on thermoforming packaging machines is challenging.

Certification

| Appearance | Black or White pigmented | ||

| Temperature range of use | 0oC - 121oC | Retort capability * | |

| Shelf-life Performance | 6 months to 2 years + | Dependant on EVOH level ** | |

| Oxygen Transmission rate | 0.2cc - 20μm/m2.day.ATM | Data from EVOH MSDS *** | |

| Water Vapour Transmission Rate | 0.37g - 0.70g - 30μm/m2/24hours | Data from EVOH MSDS *** | |

*Retort Temperature and pressure (121oC maximum)

**Product type and environment also to be taken into consideration when calculating shelflife performance

*** typical overall layer thickness of 400μm - 850μm

= OTR with EVOH @86μm = 0.001cc/M2/24hrs.Atm

= WVTR with EVOH @86μm = 0.138g /M2/24hrs.Atm

| Layer Number | Description |

| Outer Layer - 1 | Food grade, Polypropylene w/ 2% white color |

| 2 | Regrind w/ 1.25% Additive |

| 3 | Adhesive |

| 4 | EVOH |

| 5 | Adhesive |

| 6 | Regrind w/ 1.25% Additive |

| Inner Layer - 7 | Food grade Polypropylene w/ 2% white color |

Applications:

Trays, containers, clamshells, linersBenefits:

Safe and secure

Excellent thermoforming characteristics

Enhanced de-nesting properties

Good sealability

Improved temperature and impact resistance

Sustainable solution that is recyclable

Endless color options, including transparent, translucent and opaque colors

Manufactured in a controlled environment to the strictest current GMP standards

Global production redundancy

Get the latest price? We'll respond as soon as possible(within 12 hours)