TL-PET-117 HEAT SEALED CUP COVER

Moreover, the development of black PET conductive materials has opened up possibilities for their use in telecommunications, particularly in the creation of conductive fibers for smart textiles. These textiles can be integrated into wearable devices or used in other applications where flexible, conductive materials are required.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Download

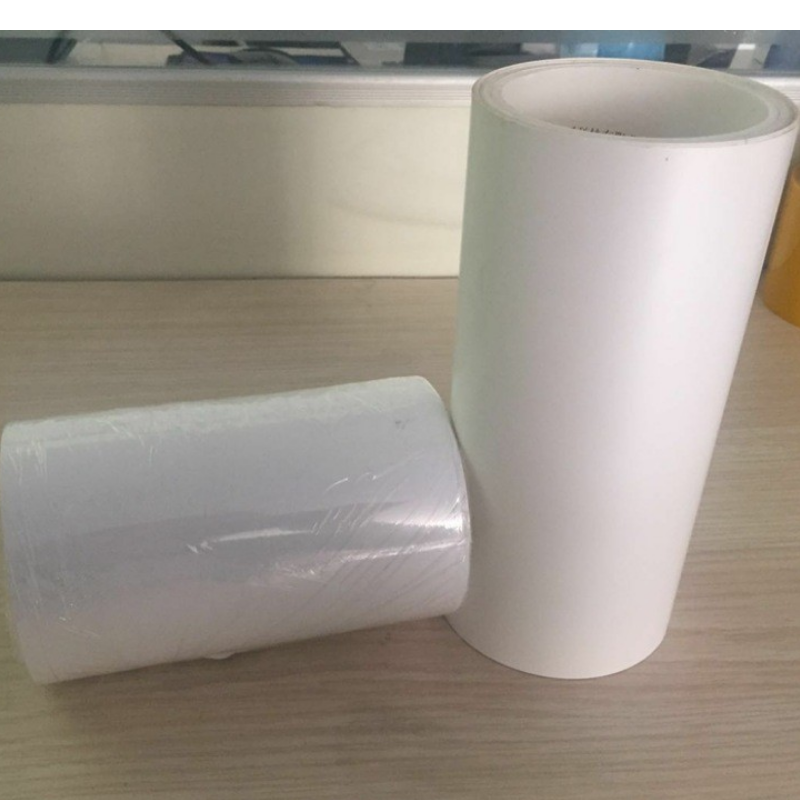

Pearl white PET (polyethylene terephthalate) film is increasingly popular in the food packaging industry, particularly as a sealing material. Its unique properties make it an ideal choice for ensuring product freshness, safety, and aesthetic appeal.

One of the key advantages of pearl white PET film is its excellent barrier properties. It effectively protects food from moisture, oxygen, and light, which are critical factors that can affect the shelf life and quality of food products. This makes pearl white PET an excellent choice for sealing perishable items such as dairy products, snacks, and ready-to-eat meals. By maintaining an optimal environment inside the packaging, pearl white PET helps to preserve the taste, texture, and nutritional value of the food.

The material's strength and durability are also significant benefits. Pearl white PET film is resistant to tearing and puncturing, ensuring that the seal remains intact during transportation and handling. This robustness is essential for maintaining the integrity of the packaging, preventing leaks, and protecting the food from external contaminants.

Another important characteristic of pearl white PET film is its heat-sealability. It can be easily sealed to a variety of substrates, such as trays, cups, and pouches, using heat-sealing equipment. The strong, reliable seals it forms are crucial for creating airtight packages that prevent spoilage and extend the product's shelf life. Moreover, the material's resistance to heat also allows it to be used in applications where the packaging is exposed to high temperatures, such as microwaveable or oven-ready meals.

Aesthetic appeal is another reason why pearl white PET is favored in food packaging. Its smooth, pearlescent finish gives the packaging a premium appearance, which can enhance the overall presentation of the product and attract consumers. The film's ability to hold vibrant colors and high-quality graphics also makes it an excellent surface for printing, allowing brands to showcase their logos, product information, and promotional designs effectively.

In addition to its functional and aesthetic qualities, pearl white PET is also an environmentally responsible choice. PET is recyclable, and the use of pearl white PET film in food packaging aligns with the growing consumer and industry demand for sustainable packaging solutions. This not only helps reduce the environmental impact of packaging waste but also meets the increasing preference for eco-friendly products.

In conclusion, pearl white PET film offers a combination of strong barrier properties, durability, heat-sealability, and visual appeal, making it an ideal material for food sealing applications. As the food packaging industry continues to evolve, the demand for high-performance materials like pearl white PET is likely to increase, driven by the need for packaging that ensures product safety, extends shelf life, and meets sustainability goals.