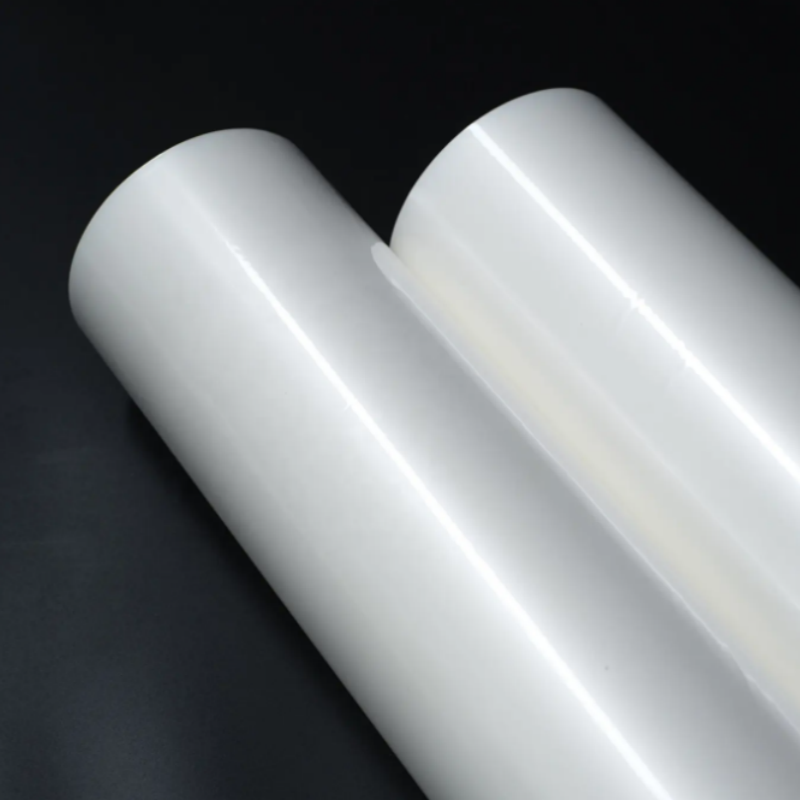

Printing BOPP Pearlized Film for Labeling Packaging

one side smooth and one side matte

- TL

- 中国

- 2024.09.31

- 1000 tons

- Information

- Video

Feature of BOPP Film

BOPP pearl film is made by mixing polypropylene resin as raw material with calcium carbonate inorganic granular pearl masterbatch, and then stretching it in both directions. It has an opaque silk like texture, a soft and pleasing pearl luster, low density, excellent flatness and gas barrier properties. Widely used for packaging dried fruits, cold drinks, candies, and high-end gifts. According to Coating Online, compared with ordinary BOPP film, BOPP pearl film has three typical characteristics: pearl luster, good light shielding, and lower density. The selection of pearl masterbatch is crucial for manufacturing BOPP pearl film. In terms of production technology, various additives and carrier PP are generally used to make pearl masterbatch, which is then added to the production line in the form of masterbatch to produce BOPP pearl film. The main component of BOPP pearl masterbatch is calcium carbonate. Due to the low adhesion of the masterbatch to PP resin, it can form countless uniform voids after stretching. When light enters the voids, interference occurs, and multi-level interference light ultimately forms the pearl effect. Calcium carbonate is an inorganic powder filler, which includes three types: heavy, light, and gelatinous. Among them, heavy calcium carbonate has irregular particle shapes and diamond shaped particles, which can improve the physical properties of products when used in plastic processing. For the production of BOPP pearl masterbatch, heavy calcium carbonate should be selected. However, when calcium bicarbonate is used for polymers, its affinity with the resin matrix is poor, often resulting in poor adhesion to the polymer matrix due to uneven dispersion, making it difficult to process and use the masterbatch. Therefore, when using calcium carbonate in the production of pearl masterbatch, it is necessary to use aluminum ester coupling agents that are conducive to making white products to treat the surface activity of calcium carbonate.

Contact:flora@sdtlplastic.cn

Get the latest price? We'll respond as soon as possible(within 12 hours)