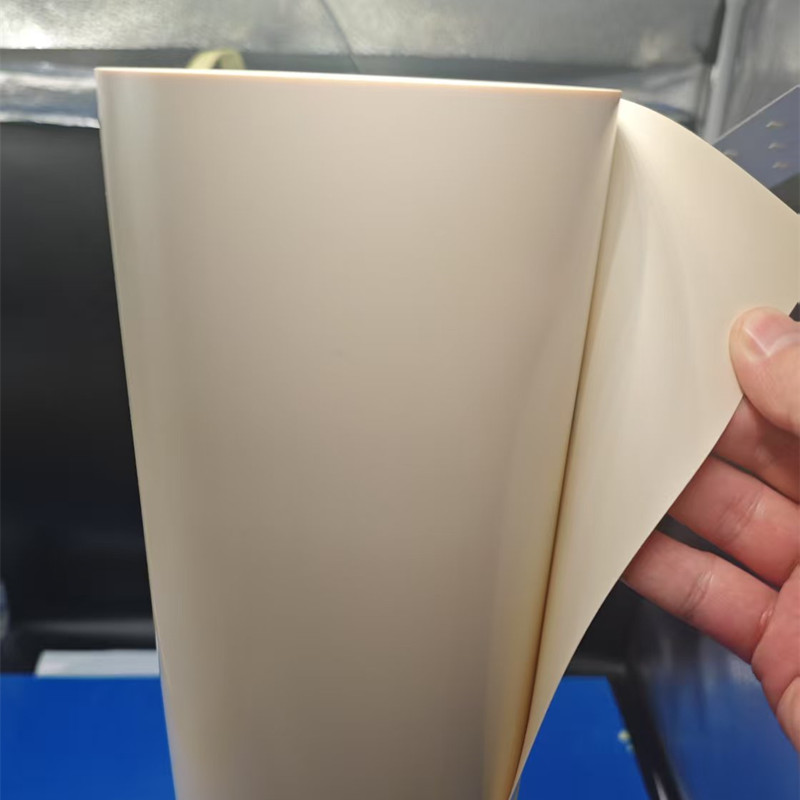

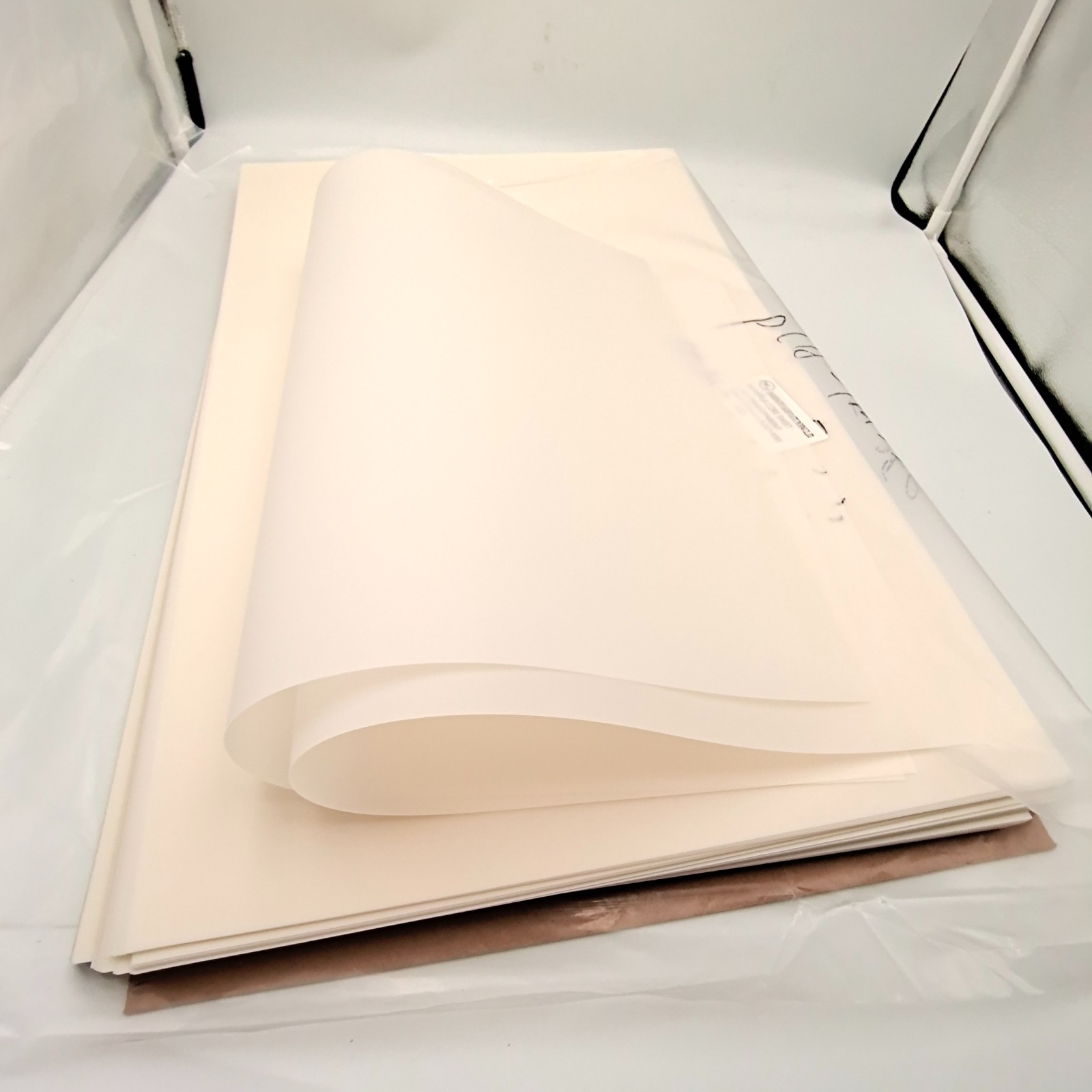

Printing Core And Overlayer Coated PLA Sheet For Cards

Printing Core And Overlayer Coated PLA Sheet For Cards

To print core and overlayer coated PLA sheet for cards, you will need the following materials and equipment:

Materials:

1. PLA filament: Choose a high-quality PLA filament in the desired color for the core layer.

2. Overlayer material: You can use a transparent PLA filament or a specialized coating material designed for 3D printing.

3. Cardstock or paper: This will be used as the base for the card.

- PLA top leader

- china

- 10 days

- 5000 tons per month

- Information

- Video

- Download

Printing Core And Overlayer Coated PLA Sheet For Cards

PLA card material Instructions for Use

1. Mounting Magnet

Low temperature is required for the lamination of PLA transparent film, and the magnetic strips need to be special low-temperature magnetic strips, otherwise high temperatures will cause shrinkage in the magnetic mounting area of the PLA film.

2. Personalization

During PLA hot stamping, some patterns are acceptable, while others may experience incomplete hot stamping. Therefore, there is a selective hot stamping mark during hot stamping, and the hot stamping parameters need to be adjusted.

The signature strip requires the use of adhesive suitable for PLA bonding.

3. Printing

①Before PLA printing, it is necessary to pre coat the primer to ensure the adhesion between the coating and the substrate after lamination. The drying temperature of the primer should not exceed 55 ℃, otherwise the sheet may easily deform;

②PLA white material needs to undergo pre pressing treatment. If it is directly printed and dried, it will deform. After pre pressing, it needs to be screen printed with a primer, otherwise the adhesive strength of the coating will not be qualified. The preloading parameters are: 80 ℃/5min.

You can choose one of the above two methods through experimentation.

4. Lamination Parameters

PLA lamination parameters: hot pressing at 135 ℃+5MPa+18min, cold pressing at 20 ℃+5MPa+18min, temperature should not exceed 135 ℃, otherwise card brittle fracture may occur.

5. Winding

Low temperature winding is required to reduce the winding speed.

If intermediate material needs to be made after winding, the recommended temperature parameter for lamination is 70 ℃+5min.

6. Aging Test

PLA cards are sensitive to temperature, and aging conditions need to be redefined. It is recommended 50 ℃+90% humidity.

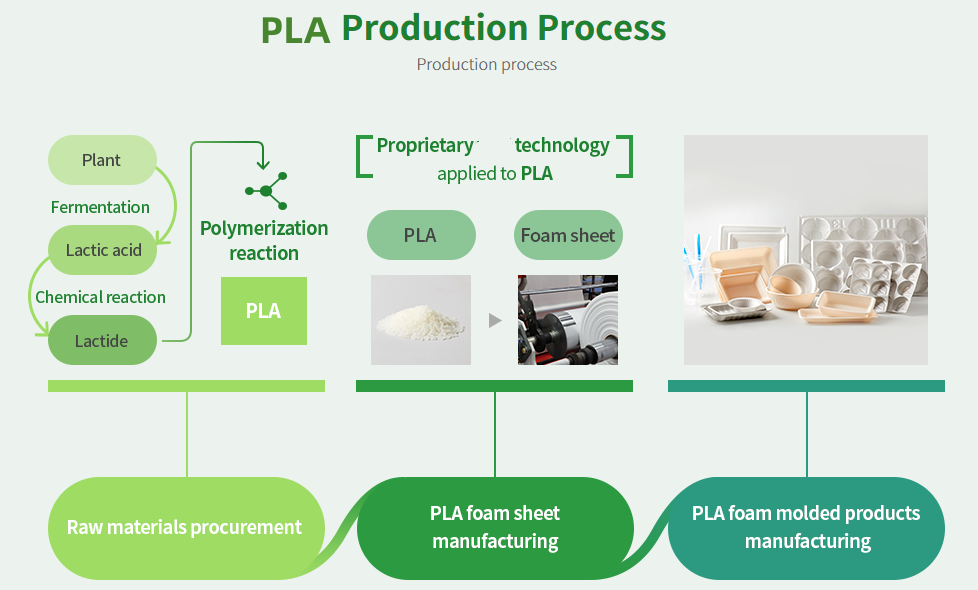

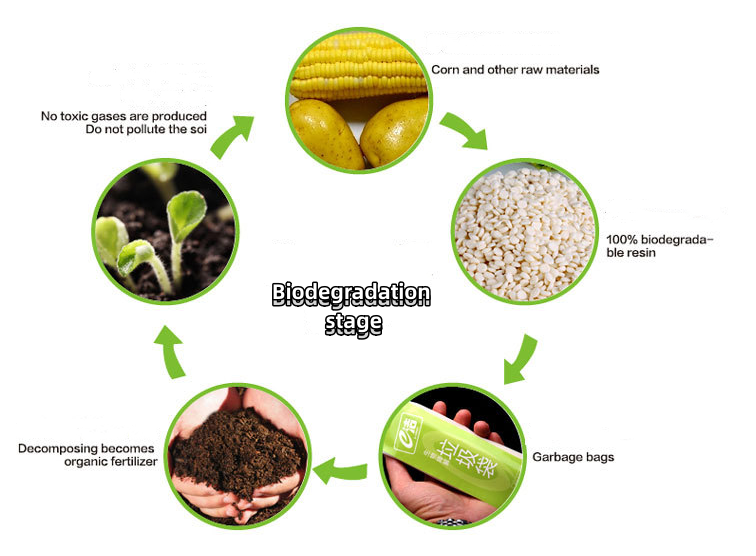

Poly(lactic acid) or polylactide (PLA) is a biodegradable thermoplastic derived from renewable resources such as corn starch, tapioca or sugar cane. PLA sheet is 100 percent biodegradable and compostable.

PLA is mainly used in the packaging industry for cups, bowls, bottles and straws. Other applications include disposable bags and trash liners as well as compostable agriculture films.

PLA Advantage:

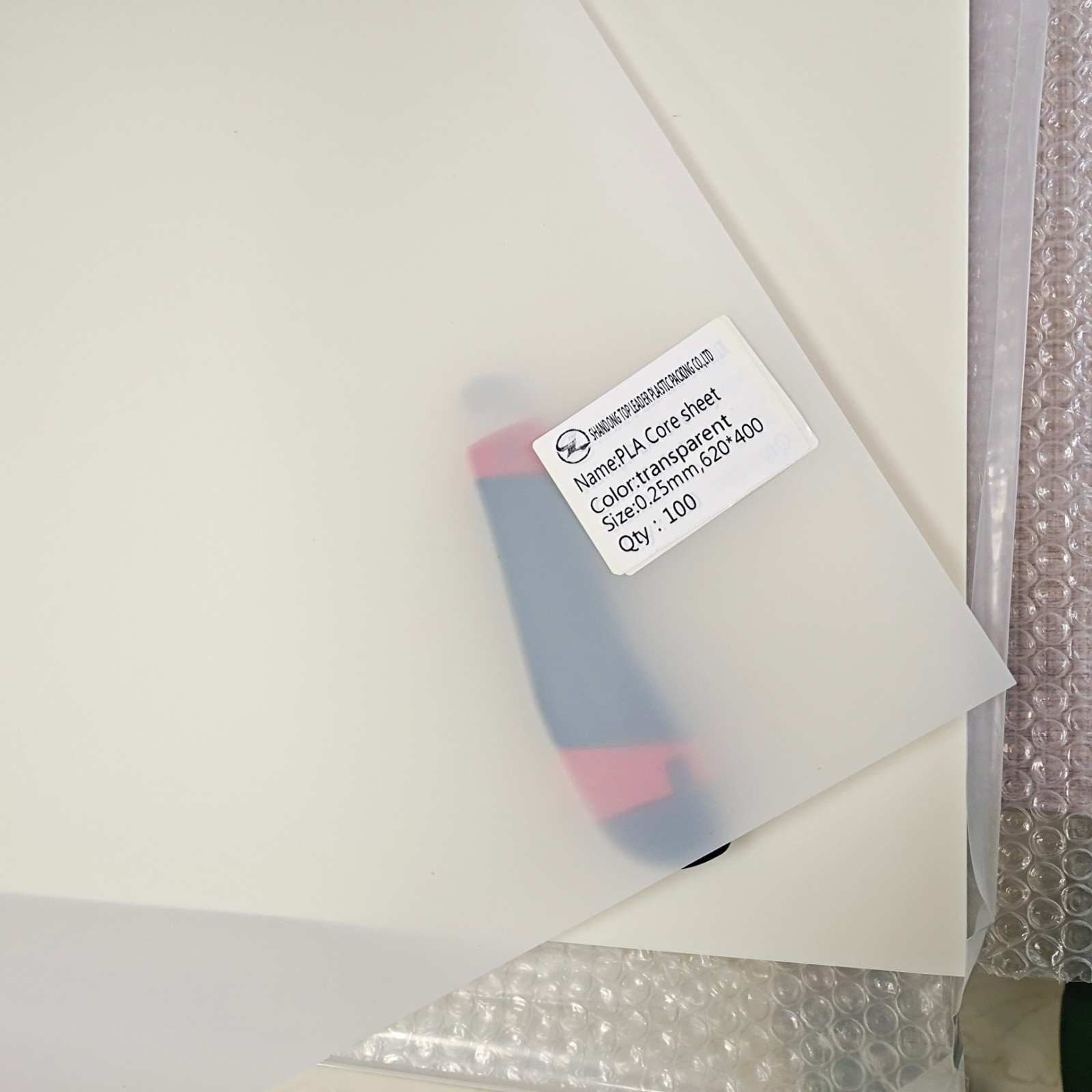

| Date: 20230310 | |||||||||

| Product name | Biodegradable transparent composite packaging PLA film | ||||||||

| Model | TLP 501 | ||||||||

| thickness | 35um-80um | ||||||||

| size | custom-made | ||||||||

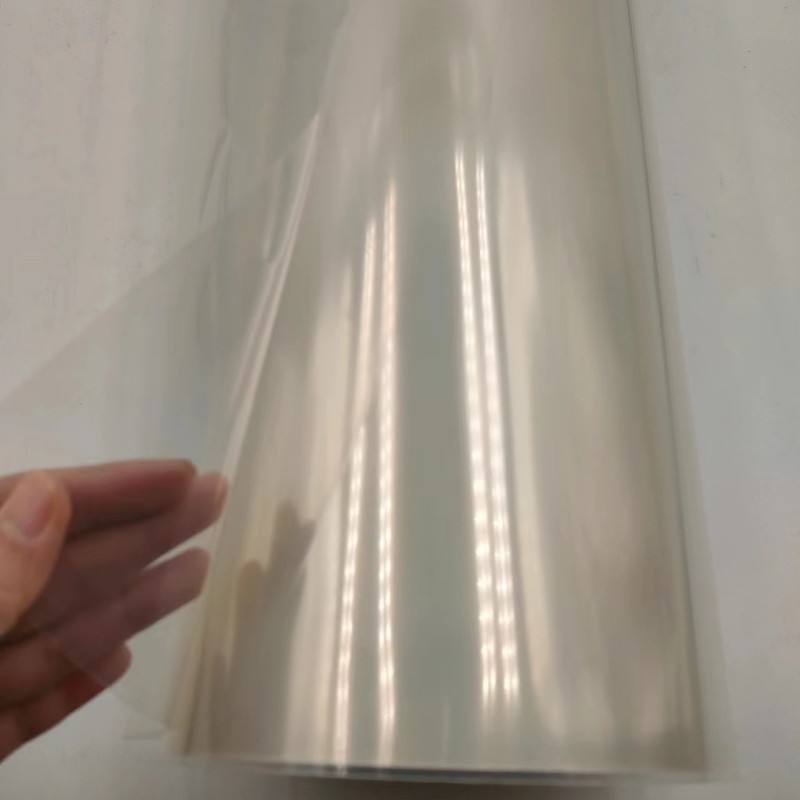

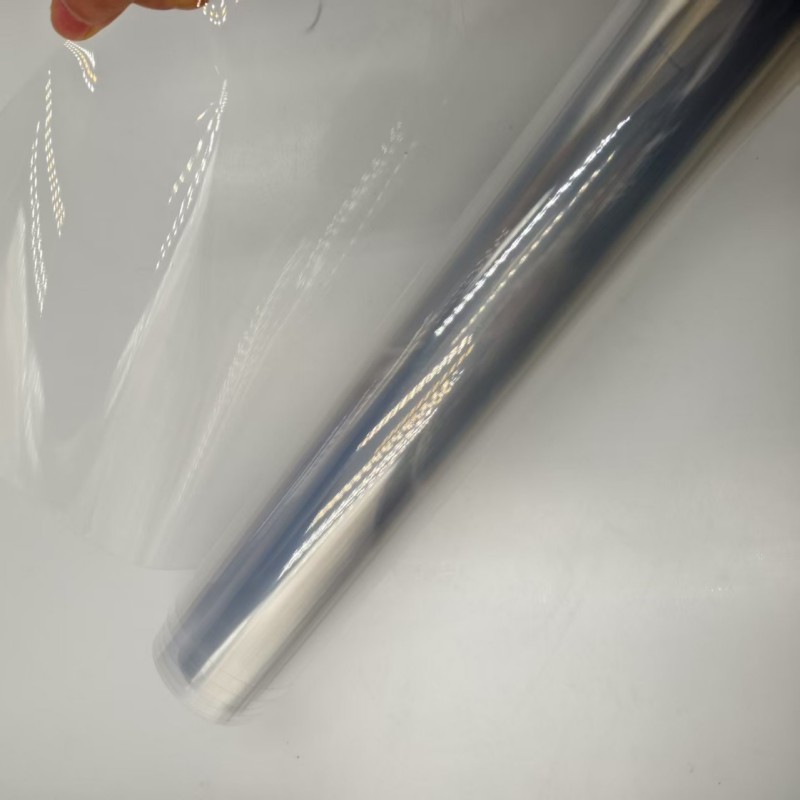

| characteristic | High transparency | ||||||||

| Water permeability (g/m2 24hrs at 38℃ 90% RH) | 5-50 | ||||||||

| Oxygen permeability • (GTR (cc/m2 24hrs atm at 23℃ 0% RH) | 0.3-3 | ||||||||

| Sealing temperature | ≥140℃ | ||||||||

| Heat sealing strength | ≥10 N | ||||||||

| Surface temperature resistance | 250 ℃ | ||||||||

| application | Packaging of dried food, dried fruit, preserved fruit and condiments and other daily necessities; | ||||||||

| Sealing film for trays, lunch boxes and drink cups | |||||||||

| High transparency and stiffness | |||||||||

| base component | Poly Lactic Acid and cellulose | ||||||||

| Compostable or not | Compostable | ||||||||

PRODUCT FEATURES:

100% biodegradable and compostable

Suitable oxygen barrier properties. Poor water vapour barrier properties.

Easy thermoforming characteristics.

High transparency and gloss.

Compostability.

Specification:

Environmentally friendly material, instead of non-degradable plastic film

Used for packaging industry like cups, bowls, bottles and straws

Used for flowers and gift packaging

Used for biomedical and pharmaceutical applications such as drug delivery systems.

The PLA PBAT film is commonly used in a variety of applications, including food packaging, disposable cutlery, agricultural films, and other single-use items. Its biodegradability and ability to be thermoformed make it a versatile and eco-friendly choice for these applications.

About Us

Shandong Top Leader Plastic Packing Co.,Ltd was established in November, 1999. As a large-scale private enterprise with more than 500 staffs, our company is a major market player in plastic film and film manufacturer at North China. Our company pursues "people oriented policy" in human resource management and persists in applying "realistic approach, innovative mentality, quality consistency and efficient administration" as our core value. Strong technical force, advanced production equipment, our company embedded 14 calender lines, 10 printing machines, 10 lamination and emboss machines to supply products of common transparent film, super transparent film, electrostatic protective film, inkjet advertising film, trademark film, protective film gum paste, electricians film, grainy film, sound film, steel film, furniture membrane pressing film, etc. Totally 64 production lines, and the production of PLA sheet ,PVC sheet, PET sheet, PETG sheet, GAG sheet ,PP sheet, PS sheet ,PC sheet widely used in food packaging, pharmaceutical packaging, electronic tray, metal packaging , Handicraft packaging and other fields.

All of our quality management is complied with ISO9001-2008 Quality Assurance Certificate and SGS Quality Assurance Certificate . We also apply "customer first, satisfaction service" to provide a comprehensive process service value on our products. As a result our products have covered all over the world market. We sincerely welcome customers and friends from home and abroad for exploration and instruction, to establish extensive cooperation and to create brilliant future together.

Our Factory

Our company embedded 14 calender lines, 10 printing machines, 10 lamination and emboss machines to supply

products of common transparent film, super transparent film, electrostatic protective film, inkjet advertising film,

trademark film, protective film gum paste, electricians film, grainy film, sound film, steel film, furniture membrane

pressing film, etc. Totally 64 production lines, and the production of PLA sheet ,PVC sheet, PET sheet, PETG sheet, GAG sheet,PP sheet, PS sheet ,PC sheet widely used in food packaging, pharmaceutical packaging, electronic tray, metal packaging,Handicraft packaging and other fields.

PACKAGING ITEM:PackingPE film inside ,Kraft paper outsider ,on pallet. 20' ft can be loaded about 18tons.Delivery within 15 days after recieve deposit

Why choose us:

1).All raw material we used are new material;

2).Skillful workers care every details in the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Our service:

1. We can provide free samples.

2. Appropriate price and high quality.

3. Various colors and various sizes,aslo accept customization.

4. A trial and sample order are acceptable .

5. Specilized with Rich experience in manufacture and export in China.

6. Secure Payment. We are Gold Supplier and Trade Assurance member, you can place the order, no

need to worry about the quality.

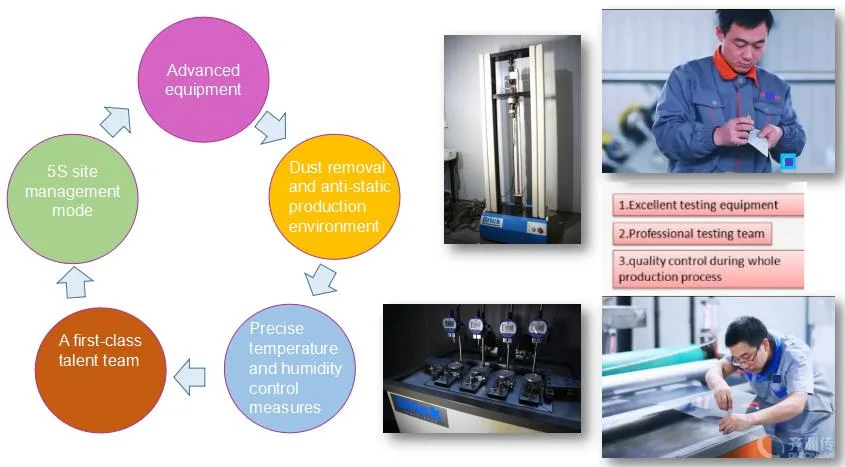

We have a complete quality inspection system.

Excellent testing equipment

Professional testing team

quality control during whole production process

Our factory has Strictly control the source of raw materials,stable and reliable raw material supplier.

Independent quality department

Stable and reliable raw material supplier

FAQ:

Q1. Is your company a factory or trading company?

A: Our company is a professional manufacturer.

Q2. What about the lead time?

A: 15days after receiving your deposit.

Q3. Do you have any MOQ?

A: Transparent PVC Sheet MOQ is 1000KG,Colorful PVC Sheet MOQ is 3000KG.

Q4. Where is your factory located? How can I visit there?

A: Our factory is located in Zibo City, Shandong Province, China.All our clients, from home or abroad, are warmly welcome to visit our company !

Q5. How can I get some samples?

A: 1,We are honored to offer you samples. New clients are expected to pay for the courier cost,the samples are free for you, this charge will be deducted from the payment for formal order.

2,Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon FedEx,UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account.Then you can pay the freight direct to your local carrier company.

Q6. How does your factory do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are new material;

2).Skillful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Within 15-20 days after received payment...more