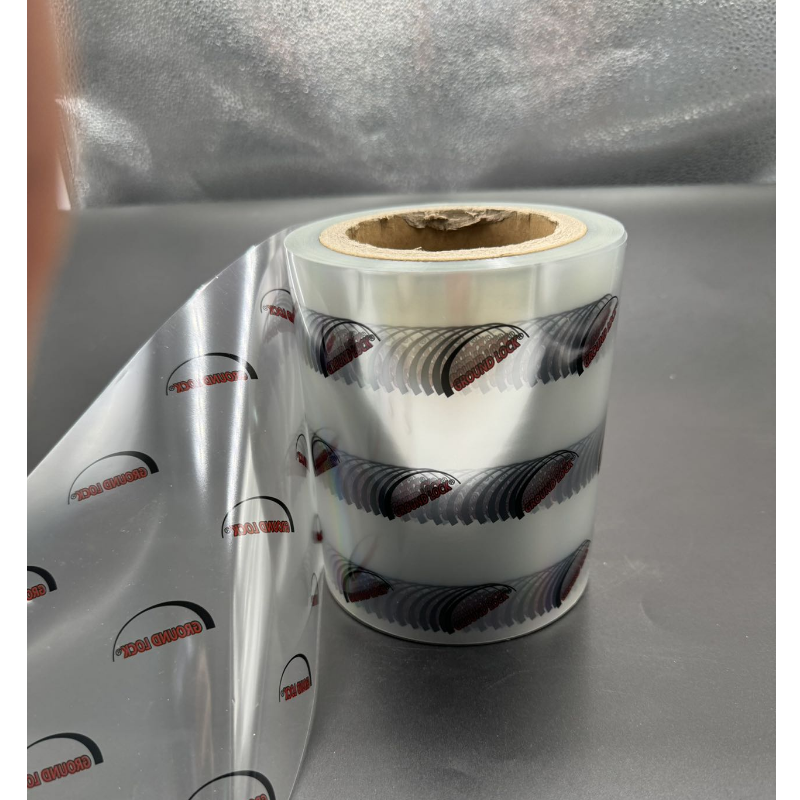

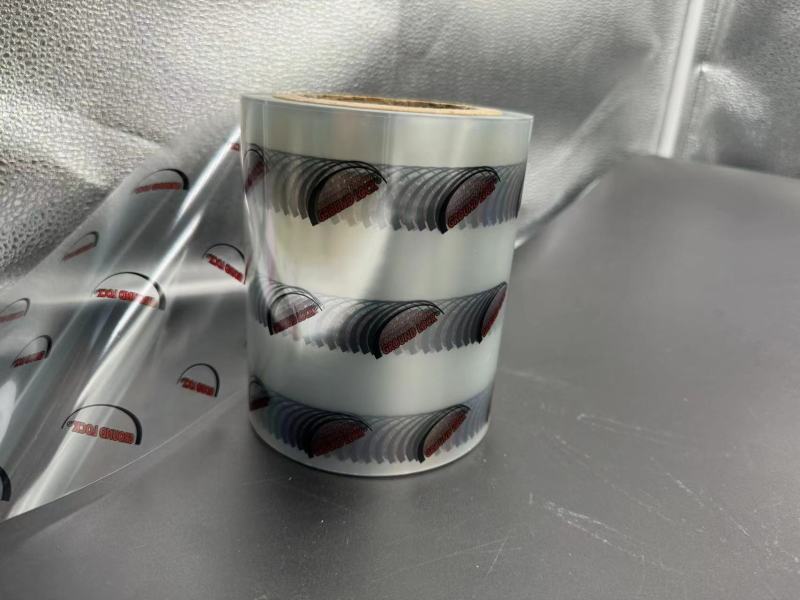

TL-PET-134 the composite pet film for cover heat sealing

3. Installation and Benefits

Installing composite PET sealing soft film for insulation is a relatively simple process. The film can be applied directly to the glass surface using an adhesive or a static cling method. Professional installation is recommended for larger projects to ensure a smooth and seamless finish.

The benefits of insulation with composite PET sealing soft film include reduced energy consumption, lower utility bills, improved comfort, and enhanced environmental sustainability. It is a cost-effective way to upgrade the insulation of a building without the need for major renovations.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

《The Versatile Applications of Composite PET Sealing Soft Film》

Introduction

Composite PET sealing soft film has emerged as a remarkable material with a wide range of applications in various fields. From adding aesthetic appeal to glass with unique textures to providing insulation, ensuring hygiene in packaging, offering electronic insulation, preventing static electricity, and serving as an effective seal for food packaging, this film has proven to be an invaluable asset. In this extensive article, we will explore the diverse uses of composite PET sealing soft film in detail, highlighting its unique properties and benefits.

I. Glass Textures with Composite PET Sealing Soft Film

1. Transforming Glass Surfaces

Composite PET sealing soft film can be used to create stunning glass textures that enhance the aesthetic appeal of any space. Whether it's for residential, commercial, or industrial settings, these films can turn plain glass into a work of art.

For example, films with frosted textures can provide privacy while still allowing natural light to filter through. This is particularly useful for bathroom windows, conference room dividers, and retail storefronts. Films with etched or patterned textures can add a touch of elegance and sophistication, making them ideal for luxury homes, hotels, and high-end offices.

2. Customization Options

One of the great advantages of composite PET sealing soft film is its ability to be customized. Different textures, colors, and designs can be created to meet the specific needs and preferences of each customer. This allows for endless creative possibilities and ensures that every application is unique.

For instance, a homeowner may choose a film with a floral pattern to add a feminine touch to a bedroom window. A business owner may opt for a film with a corporate logo or brand colors to promote their company. The customization options make composite PET sealing soft film a popular choice for both personal and professional applications.

3. Durability and Easy Maintenance

Composite PET sealing soft film is not only aesthetically pleasing but also highly durable. It can withstand daily wear and tear, exposure to sunlight, and temperature changes without fading or peeling. Additionally, the film is easy to clean and maintain, requiring only a simple wipe with a damp cloth.

This durability and ease of maintenance make it a practical choice for long-term use. Whether it's on a residential window that needs to withstand the elements or a commercial glass partition that experiences heavy traffic, composite PET sealing soft film can hold up over time.

II. Insulation with Composite PET Sealing Soft Film

1. Thermal Insulation

Composite PET sealing soft film provides excellent thermal insulation properties, helping to regulate the temperature inside a building. By reducing heat transfer through glass, it can keep interiors cooler in summer and warmer in winter, resulting in energy savings and increased comfort.

For residential homes, this can mean lower heating and cooling costs. In commercial buildings, it can contribute to a more sustainable and energy-efficient operation. The film works by reflecting infrared radiation and reducing the amount of heat that enters or escapes through the glass.

2. Sound Insulation

In addition to thermal insulation, composite PET sealing soft film also offers some sound insulation benefits. It can help reduce noise transmission through glass, creating a quieter and more peaceful environment.

This is especially valuable in urban areas where traffic noise, construction noise, and other sources of noise can be a nuisance. By installing sound-insulating films on windows and doors, residents and businesses can enjoy a more serene atmosphere.

3. Installation and Benefits

Installing composite PET sealing soft film for insulation is a relatively simple process. The film can be applied directly to the glass surface using an adhesive or a static cling method. Professional installation is recommended for larger projects to ensure a smooth and seamless finish.

The benefits of insulation with composite PET sealing soft film include reduced energy consumption, lower utility bills, improved comfort, and enhanced environmental sustainability. It is a cost-effective way to upgrade the insulation of a building without the need for major renovations.

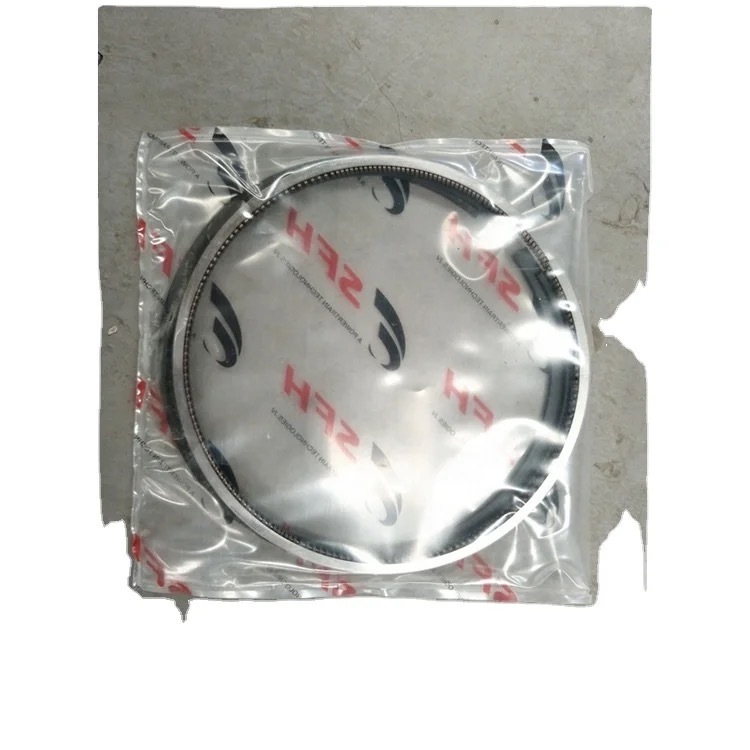

III. Hygienic Packaging with Composite PET Sealing Soft Film

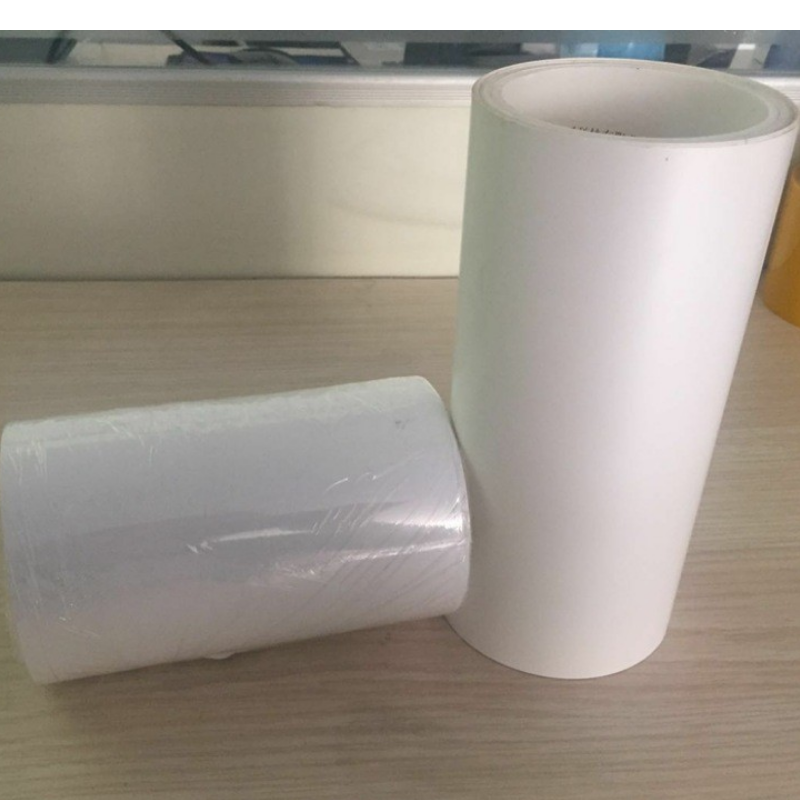

1. Food Packaging

Composite PET sealing soft film is widely used in food packaging due to its excellent barrier properties. It can prevent the passage of moisture, oxygen, and other gases, helping to preserve the freshness and quality of food products.

For example, the film can be used to seal packages of snacks, cookies, chocolates, and other dry foods. It can also be used for packaging fresh produce, meats, and dairy products, providing a protective barrier against spoilage. The film can be printed with product information, nutritional facts, and expiration dates, making it easy for consumers to identify and select the right products.

2. Medical Packaging

In the medical field, composite PET sealing soft film is used for packaging sterile medical devices, pharmaceuticals, and other healthcare products. The film provides a reliable barrier against contaminants, ensuring the safety and integrity of the packaged items.

Medical packaging films often meet strict regulatory requirements for cleanliness and sterility. Composite PET sealing soft film can be customized to meet these standards, providing a trusted solution for the healthcare industry.

3. Hygiene and Safety

Composite PET sealing soft film is made from materials that are safe for contact with food and medical products. It is free from harmful substances such as BPA and phthalates, ensuring the safety of consumers. Additionally, the film can be easily cleaned and disinfected, making it suitable for use in environments where hygiene is a top priority.

IV. Electronic Insulation with Composite PET Sealing Soft Film

1. Insulating Properties for Electronics

Composite PET sealing soft film is an excellent insulator for electronic components and devices. It can prevent electrical shorts and protect sensitive electronics from damage caused by static electricity, moisture, and other environmental factors.

For example, the film can be used as an insulation layer in printed circuit boards (PCBs). It can also be used to wrap cables and wires, providing electrical isolation and mechanical protection. The film's high dielectric strength and low moisture absorption make it ideal for use in electronic applications.

2. High Dielectric Strength

Composite PET sealing soft film has a high dielectric strength, which means it can withstand high voltages without breaking down. This property is crucial for electronic insulation, as it helps prevent electrical failures and ensures the safe operation of electronic devices.

The dielectric strength of the film can be adjusted by varying its thickness and composition. Thicker films and films with higher levels of additives can provide greater insulation and dielectric strength.

3. Thermal Stability

In addition to its electrical insulation properties, composite PET sealing soft film also offers thermal stability. It can withstand high temperatures without degrading or losing its insulating properties. This is important for electronic applications where components may generate heat during operation.

The film's thermal stability helps prevent overheating and protects sensitive electronics from damage. It also allows for use in environments with elevated temperatures, such as industrial settings or automotive applications.

V. Anti-Static Properties of Composite PET Sealing Soft Film

1. Preventing Static Build-up

Static electricity can cause problems in many industries, especially in electronics manufacturing and packaging. Composite PET sealing soft film with anti-static properties can help prevent static build-up and reduce the risk of damage to sensitive electronic components.

The anti-static properties of the film are achieved by adding conductive additives or coating the film with a conductive layer. These additives or coatings allow static electricity to be dissipated safely, preventing it from accumulating on the film or the packaged items.

2. Applications in Electronics and Other Industries

Anti-static composite PET sealing soft films are widely used in the electronics industry for packaging integrated circuits, printed circuit boards, and other sensitive components. The films help protect the components from electrostatic discharge (ESD) during handling, transportation, and storage.

In addition to electronics, anti-static films are also used in other industries such as healthcare, aerospace, and automotive. For example, in healthcare, anti-static films are used for packaging sterile medical devices to prevent static build-up that could attract dust and contaminants. In aerospace and automotive, anti-static films are used to protect sensitive electronic systems from ESD.

3. Benefits and Considerations

The benefits of using anti-static composite PET sealing soft film include reduced risk of damage to sensitive electronics, improved product quality, and increased safety. However, it is important to note that the effectiveness of anti-static films can be affected by factors such as humidity, temperature, and the type of packaging materials used.

When choosing anti-static film, it is important to consider the specific requirements of the application and select a film with the appropriate level of anti-static protection.

VI. Food Packaging Sealing with Composite PET Sealing Soft Film

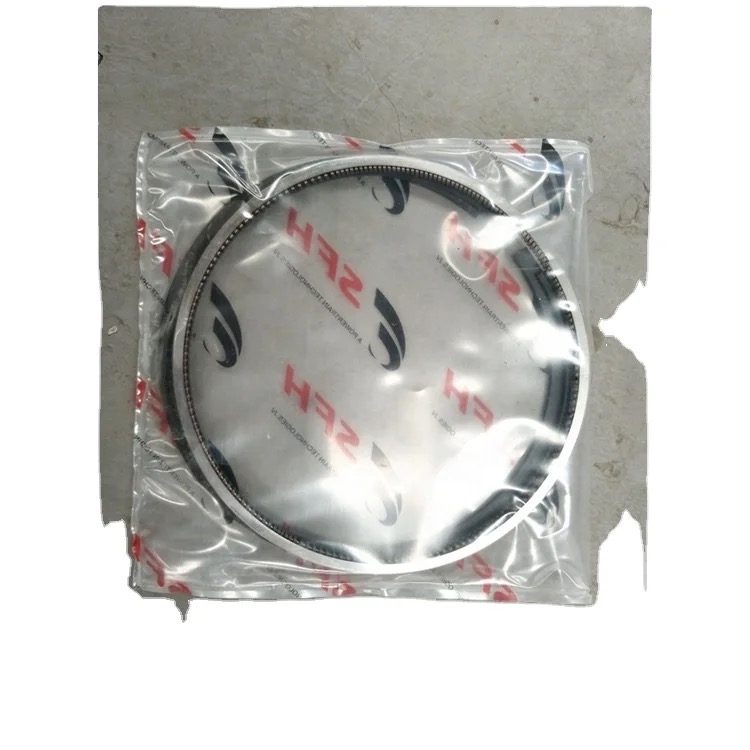

1. Effective Sealing Mechanism

Composite PET sealing soft film is designed to provide a reliable seal for food packaging. The film can be heat-sealed, cold-sealed, or pressure-sealed, depending on the packaging requirements.

Heat-sealing is a common method where the film is heated to a specific temperature to melt the sealing layer and create a strong bond. Cold-sealing uses an adhesive or a pressure-sensitive layer to seal the package without the need for heat. Pressure-sealing involves applying pressure to the film to create a seal.

The sealing mechanism ensures that the package is airtight and moisture-proof, helping to preserve the freshness and quality of the food inside. It also provides tamper-evident protection, giving consumers confidence in the integrity of the product.

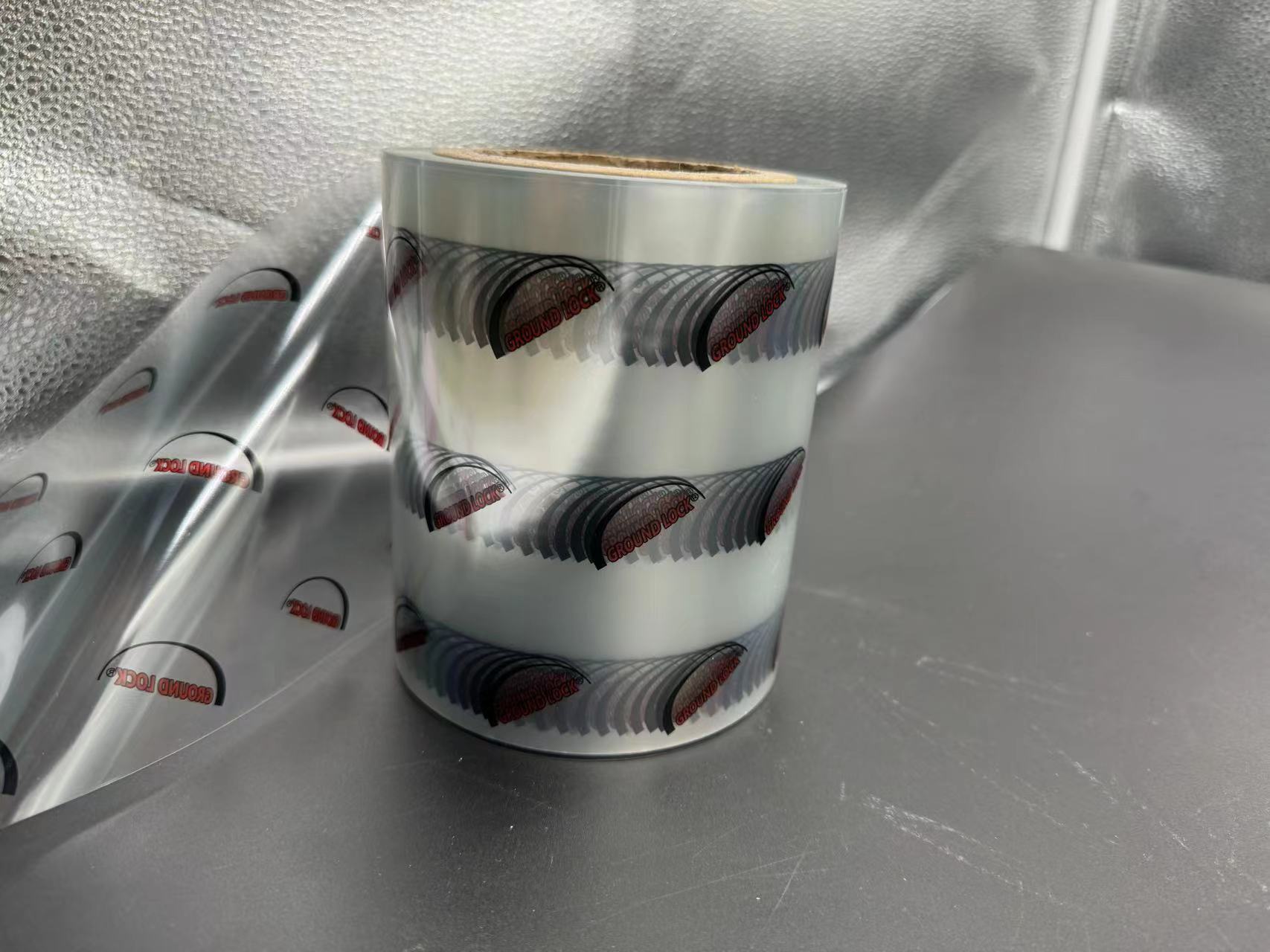

2. Customization for Different Food Products

Composite PET sealing soft film can be customized to meet the specific needs of different food products. For example, films with different barrier properties can be used for packaging fresh produce, meats, dairy products, and dry foods. Films with different thicknesses and strengths can be selected based on the size and weight of the packaged items.

The film can also be printed with product information, branding, and nutritional facts, making it an effective marketing tool. Additionally, films with special features such as easy-open tabs or resealable closures can be used to enhance the convenience of the packaging.

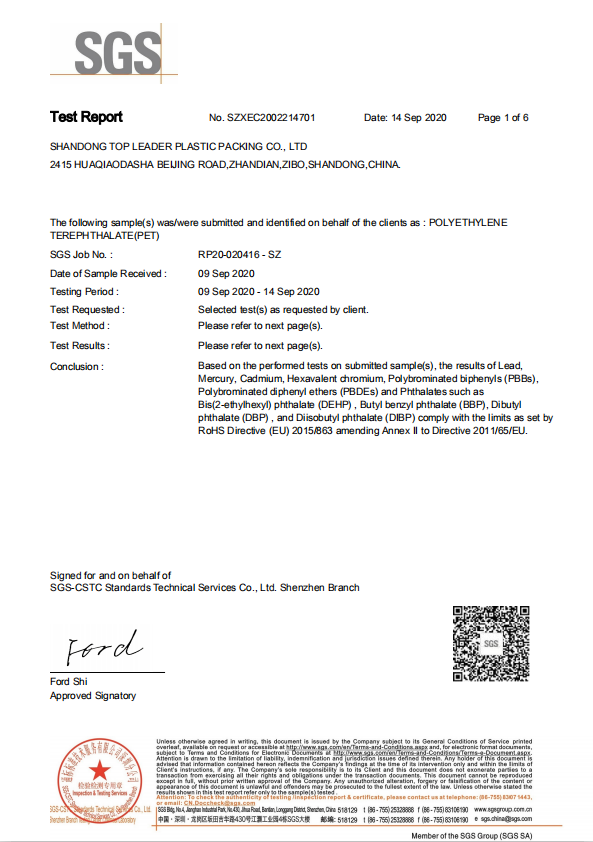

3. Safety and Compliance

Food packaging films must meet strict safety and regulatory requirements. Composite PET sealing soft film is made from materials that are approved for food contact and comply with relevant food safety standards.

The film is tested for its barrier properties, strength, and seal integrity to ensure that it provides effective protection for food products. Manufacturers must also ensure that their packaging processes are compliant with food safety regulations to protect consumers and maintain the reputation of their products.

Conclusion

Composite PET sealing soft film is a truly versatile material with a wide range of applications in different fields. From adding aesthetic appeal to glass with unique textures to providing insulation, ensuring hygiene in packaging, offering electronic insulation, preventing static electricity, and serving as an effective seal for food packaging, this film has proven its value time and again. With its unique properties and benefits, composite PET sealing soft film is sure to continue playing an important role in various industries for years to come. Whether you are a designer, manufacturer, or consumer, this film offers a practical and stylish solution for your needs.

Within 15-20 days after received payment...more