Polypropylene PP plastic sheet roll

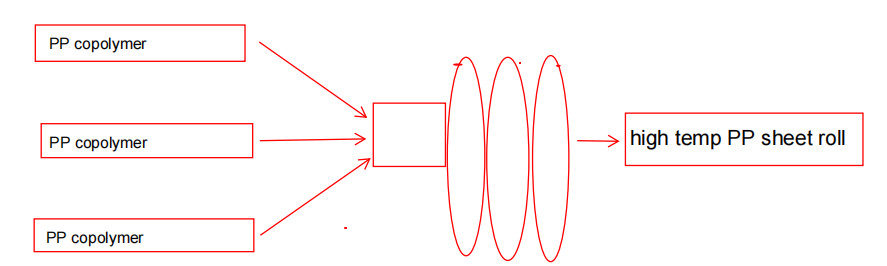

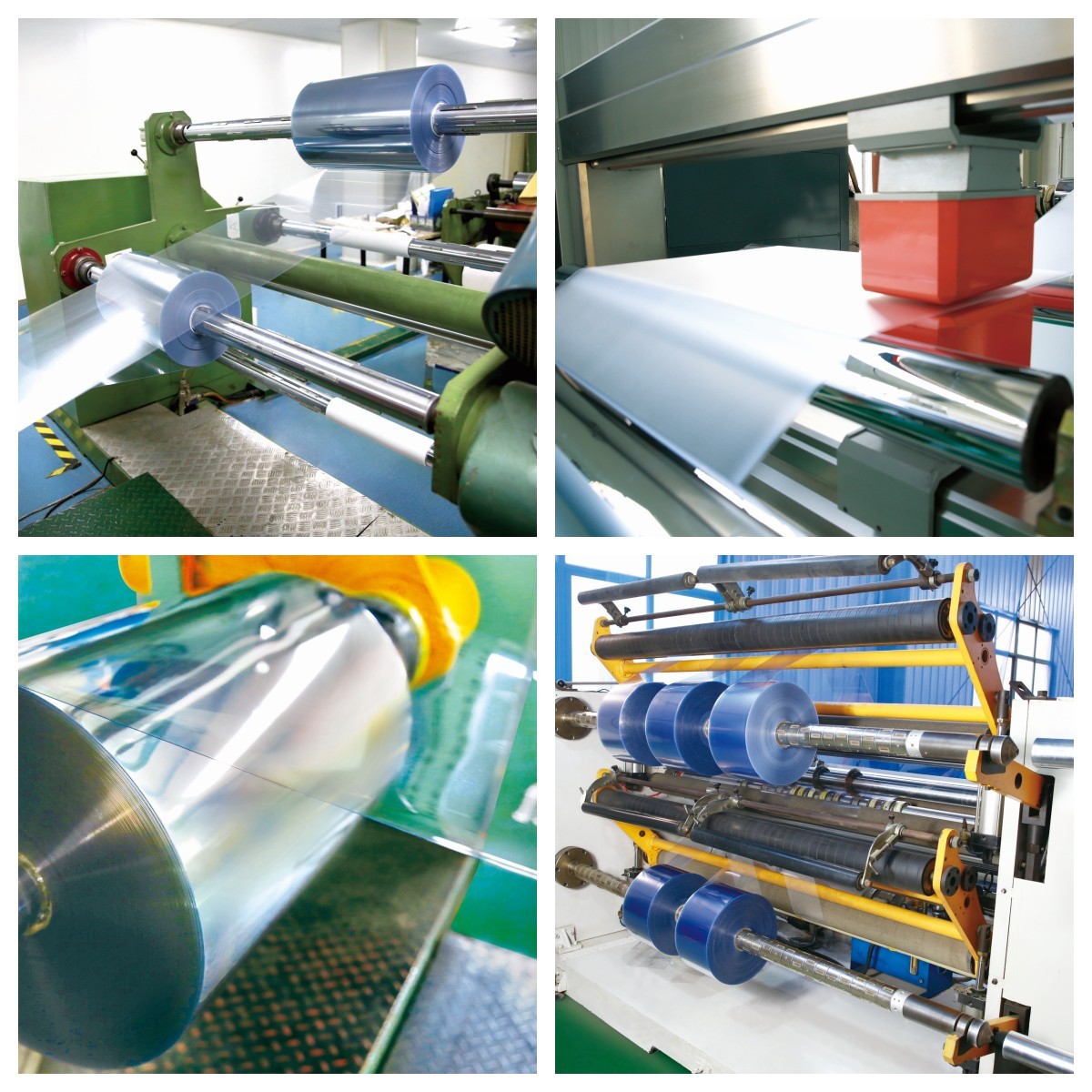

Polypropylene PP plastic sheet roll is a polymer formed by addition polymerization of propylene. It is a colorless, odorless, non-toxic, and translucent solid substance. Polypropylene particles are dyed, plasticized at high temperature and extruded into polystyrene sheets. PP sheets have chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties and good high wear-resistant processing properties. PP sheet has high transparency, good barrier properties, low density, non-toxic and hygienic, and can be recycled. It will not produce toxic and harmful gases when heated or burned, does not harm human health, and does not corrode equipment. It is a new type green environmental protection packaging materials.