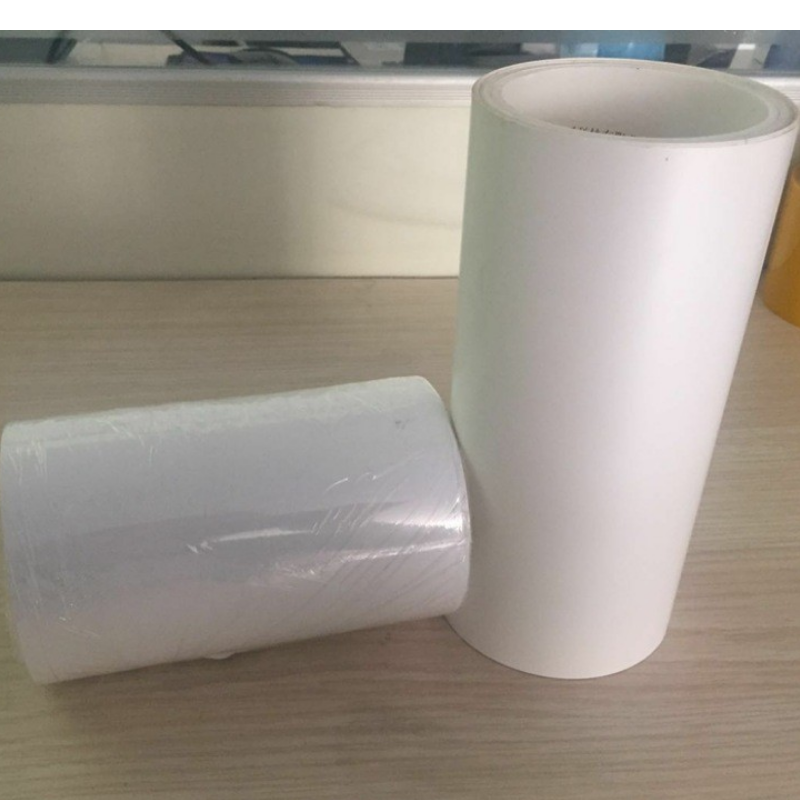

TL-PET-127 WHITE PET FILM APPLICATION

1. UV Resistance: One of the key features of white PET film is its excellent resistance to ultraviolet rays. This property makes it highly suitable for packaging products that are sensitive to light and need protection from UV degradation. For example, in the pharmaceutical and cosmetic industries, where products can lose their potency or change color due to exposure to UV light, white PET film provides a reliable barrier.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

The Versatile Applications of White PET Film in Packaging and Decoration

Introduction

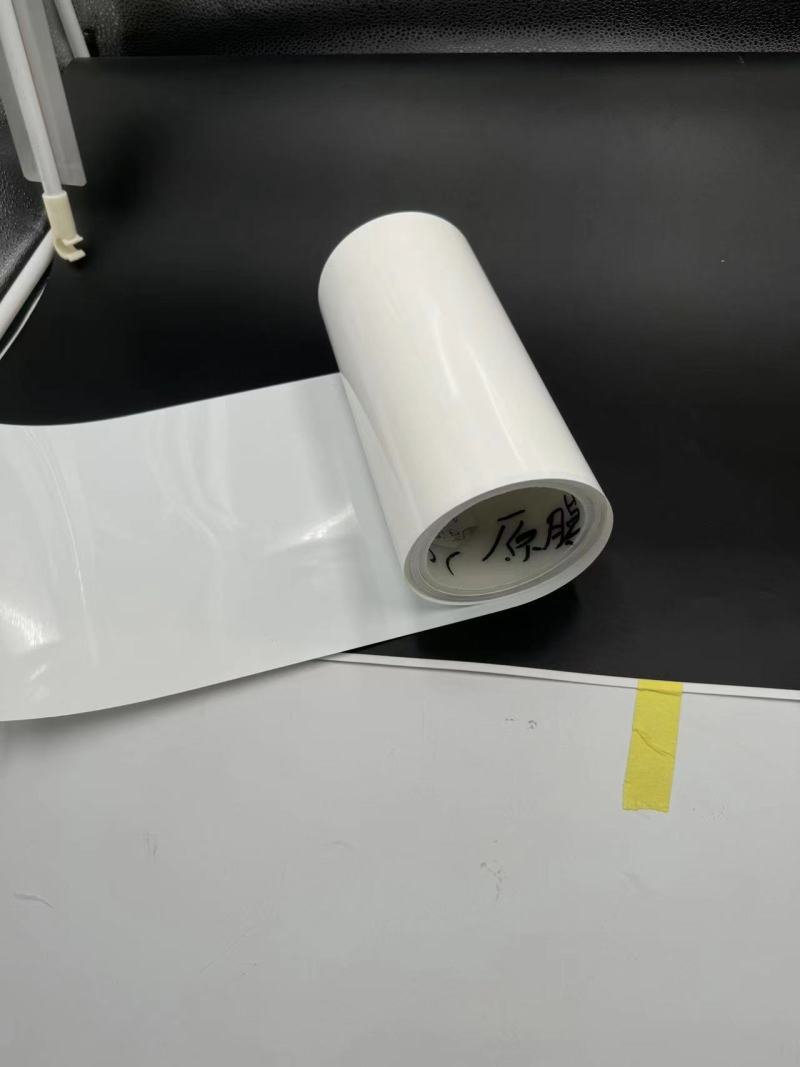

In the world of materials, white PET film stands out as a remarkable and highly versatile option. With its unique properties and numerous applications, it has become an essential component in various industries. From providing excellent protection against ultraviolet (UV) rays in packaging to enhancing the aesthetic appeal in decoration, white PET film plays a crucial role. In this extensive article, we will explore the diverse applications of white PET film in anti-UV packaging, pharmaceutical packaging, food packaging, and decoration.

I. Properties of White PET Film

White PET film possesses several characteristics that make it an ideal choice for different applications. Some of these properties include:

1. UV Resistance: One of the key features of white PET film is its excellent resistance to ultraviolet rays. This property makes it highly suitable for packaging products that are sensitive to light and need protection from UV degradation. For example, in the pharmaceutical and cosmetic industries, where products can lose their potency or change color due to exposure to UV light, white PET film provides a reliable barrier.

2. Transparency and Clarity: Despite its white color, white PET film offers a certain degree of transparency and clarity. This allows for easy inspection of the packaged products and enhances their visual appeal. In food packaging, for instance, it enables consumers to see the contents inside, instilling confidence in the product's quality.

3. Durability and Strength: White PET film is known for its durability and strength. It can withstand rough handling, impacts, and abrasions, ensuring that the packaged products remain safe and intact during transportation and storage. This makes it suitable for a wide range of applications, from packaging delicate items to industrial products.

4. Chemical Resistance: The film has good chemical resistance, which means it can resist the effects of various chemicals and solvents. This property is particularly useful in the pharmaceutical and chemical industries, where products may come into contact with different substances.

5. Heat Resistance: White PET film can withstand high temperatures without deforming or melting. This makes it suitable for applications that involve heat sealing or sterilization processes, such as in pharmaceutical and food packaging.

6. Printability: The film can be easily printed with high-quality graphics and labels, allowing for effective branding and product identification. This makes it an attractive option for marketing and promotional purposes.

II. Applications in Anti-UV Packaging

1. Pharmaceuticals

• In the pharmaceutical industry, many drugs and medications are sensitive to UV light. Exposure to UV rays can cause these products to degrade, lose their potency, or even become harmful. White PET film provides an effective solution by acting as a barrier against UV radiation. It is commonly used in blister packs, bottles, and pouches for packaging pharmaceuticals.

• For example, blister packs made of white PET film are widely used for packaging tablets and capsules. The film not only protects the medications from UV light but also provides a tamper-evident seal and easy-to-open packaging. Bottles and pouches made of white PET film are also used for packaging liquid and powder medications, ensuring their stability and integrity.

2. Cosmetics

• Cosmetic products, such as lotions, creams, and serums, are often sensitive to UV light and can lose their effectiveness or change color if exposed. White PET film is used in packaging these products to provide UV protection. It is commonly used in tubes, jars, and bottles for cosmetics packaging.

• The transparency and clarity of white PET film allow consumers to see the product inside, while the UV resistance ensures that the product remains stable and effective. Additionally, the film can be printed with attractive designs and labels, enhancing the product's visual appeal and marketing.

3. Electronics

• Electronic components, such as integrated circuits, transistors, and capacitors, can be damaged by UV light. White PET film is used in packaging these components to provide UV protection. It is commonly used in trays, reels, and bags for packaging electronic components.

• The film's durability and strength ensure that the components remain safe during transportation and storage, while the UV resistance protects them from light-induced damage. Additionally, the film can be customized with different thicknesses and sizes to meet the specific requirements of different electronic components.

III. Applications in Pharmaceutical Packaging

1. Blister Packs

• Blister packs made of white PET film are widely used in the pharmaceutical industry for packaging tablets, capsules, and other solid dosage forms. The film provides a clear and transparent barrier that allows for easy inspection of the product while protecting it from moisture, oxygen, and light.

• The blister packs can be designed with different shapes and sizes to fit the specific requirements of different medications. They can also be printed with important information such as dosage instructions, expiration dates, and manufacturer details.

2. Bottles and Vials

• White PET bottles and vials are commonly used for packaging liquid and powder medications. The film's chemical resistance and heat resistance make it suitable for containing different types of pharmaceuticals. The bottles and vials can be equipped with various closures, such as screw caps, droppers, and spray pumps, depending on the application.

• The transparency and clarity of white PET film allow for easy inspection of the product inside, while the UV resistance protects the medication from light-induced degradation. Additionally, the film can be printed with labels and markings for easy identification and use.

3. Pouches and Sachets

• Pouches and sachets made of white PET film are used for packaging powdered and granular medications. The film's flexibility and sealability make it easy to package these products in small quantities while providing a barrier against moisture, oxygen, and light.

• The pouches and sachets can be designed with tear-notches or easy-open features for convenient use by consumers. They can also be printed with product information and branding.

IV. Applications in Food Packaging

1. Fresh Produce Packaging

• White PET film is used in packaging fresh fruits and vegetables to provide protection against moisture, oxygen, and light. The film's transparency and clarity allow consumers to see the product inside, while the UV resistance helps to preserve the freshness and nutritional value of the produce.

• For example, white PET film is commonly used in packaging salads, berries, and cut fruits. The film can be made into bags, trays, or wraps, depending on the specific requirements of the product.

2. Meat and Poultry Packaging

• White PET film is used in packaging meat and poultry products to provide a barrier against moisture, oxygen, and light. The film's durability and strength ensure that the products remain safe during transportation and storage, while the UV resistance helps to prevent spoilage.

• Vacuum-sealed bags made of white PET film are commonly used for packaging fresh meat and poultry. The film's heat resistance allows for heat sealing, ensuring a tight seal and preventing the ingress of air and moisture.

3. Snack Foods Packaging

• Snack foods, such as chips, cookies, and nuts, require packaging that provides protection against moisture, oxygen, and light. White PET film is used in packaging these products to ensure their freshness and quality.

• The film can be made into bags, pouches, or trays, depending on the specific requirements of the snack food. It can also be printed with attractive designs and labels to enhance the product's visual appeal and marketing.

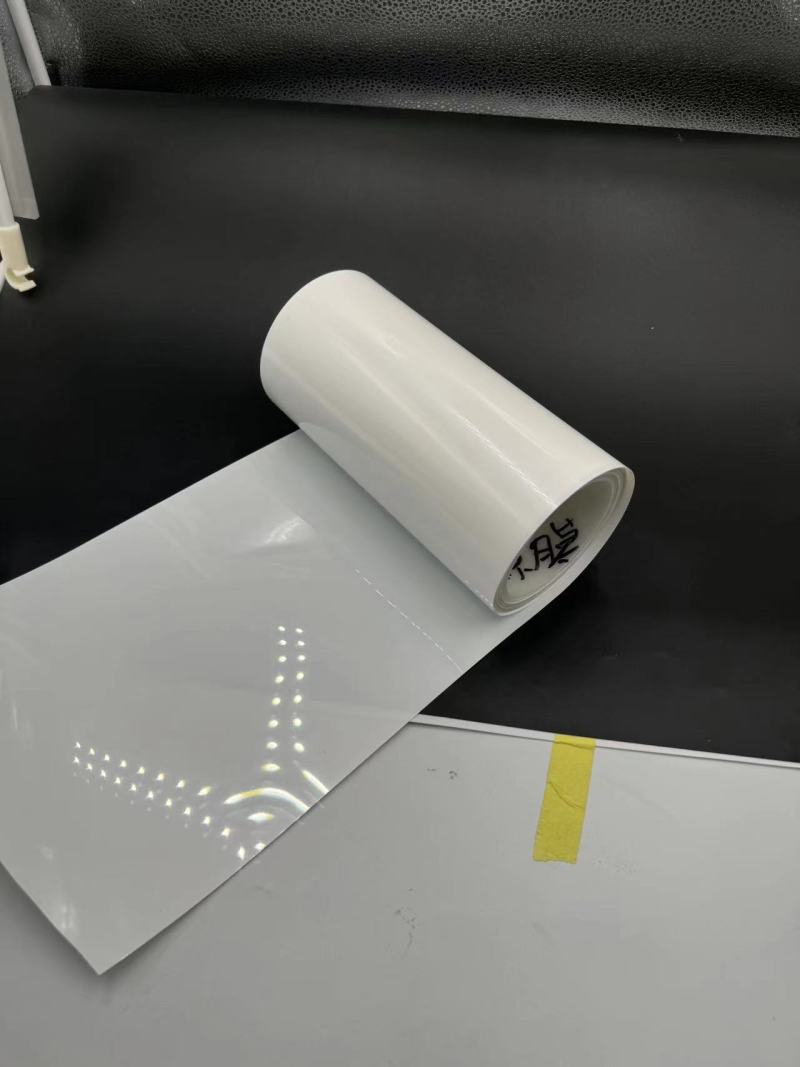

V. Applications in Decoration

1. Wall Decals and Stickers

• White PET film is used in making wall decals and stickers. The film's printability and durability make it suitable for creating high-quality and long-lasting decorative elements. Wall decals and stickers made of white PET film can be easily applied and removed without leaving any residue.

• They can be printed with various designs, patterns, and colors, allowing for endless possibilities in interior decoration. Whether it's a floral pattern, a geometric design, or a personalized message, white PET film wall decals and stickers can add a unique touch to any room.

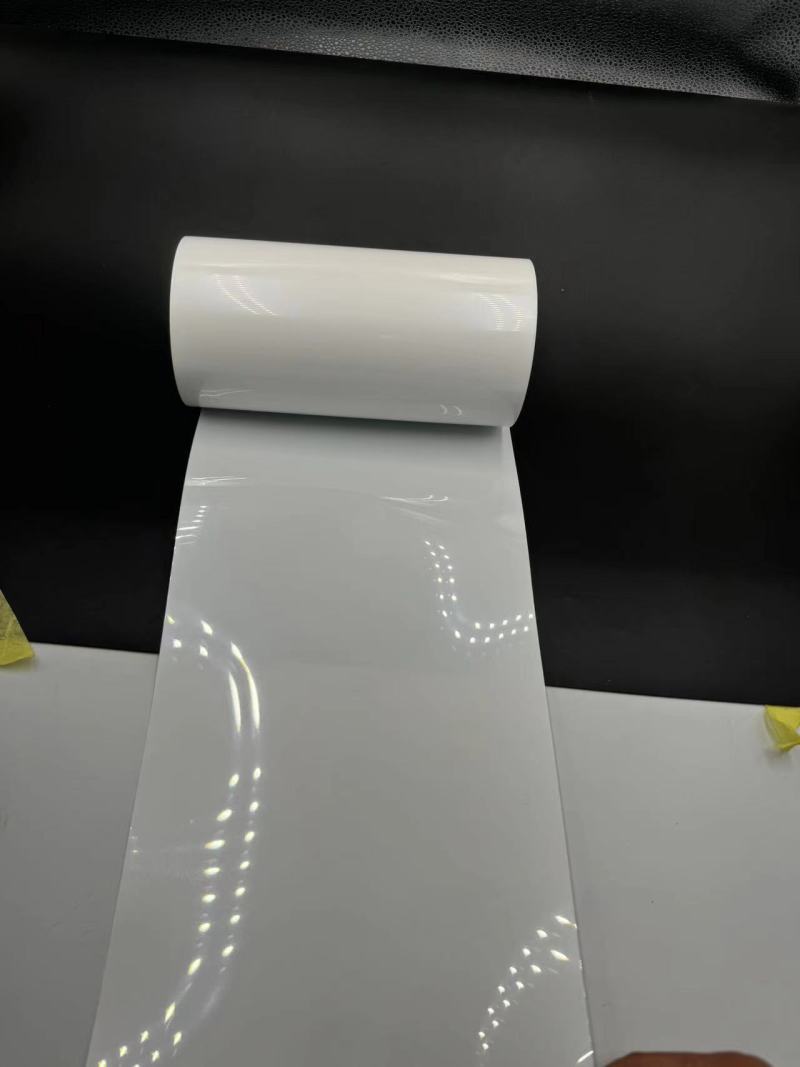

2. Window Films

• White PET window films are used for decorative and functional purposes. They can provide privacy, reduce glare, and block UV rays while adding an aesthetic appeal to windows. The film can be tinted or patterned to create different effects.

• For example, frosted white PET window films can create a semi-transparent effect, providing privacy while still allowing light to pass through. Decorative patterns and designs can be printed on the film to enhance the visual appeal of windows.

3. Signage and Displays

• White PET film is used in making signs and displays for advertising, promotions, and information purposes. The film's printability and durability make it suitable for creating high-quality and long-lasting signage. Signs and displays made of white PET film can be used indoors and outdoors.

• They can be printed with vibrant colors and graphics, making them highly visible and attention-grabbing. Whether it's a store sign, a promotional banner, or an informational display, white PET film signage and displays can effectively communicate messages and attract customers.

VI. Conclusion

White PET film is a versatile and highly useful material with a wide range of applications in anti-UV packaging, pharmaceutical packaging, food packaging, and decoration. Its unique properties, such as UV resistance, transparency, durability, chemical resistance, heat resistance, and printability, make it an ideal choice for different industries. Whether it's protecting sensitive products from UV degradation, ensuring the safety and integrity of pharmaceuticals, preserving the freshness of food, or adding a decorative touch to interiors, white PET film plays a crucial role. As technology continues to advance, we can expect to see even more innovative applications of white PET film in the future.

Within 15-20 days after received payment...more