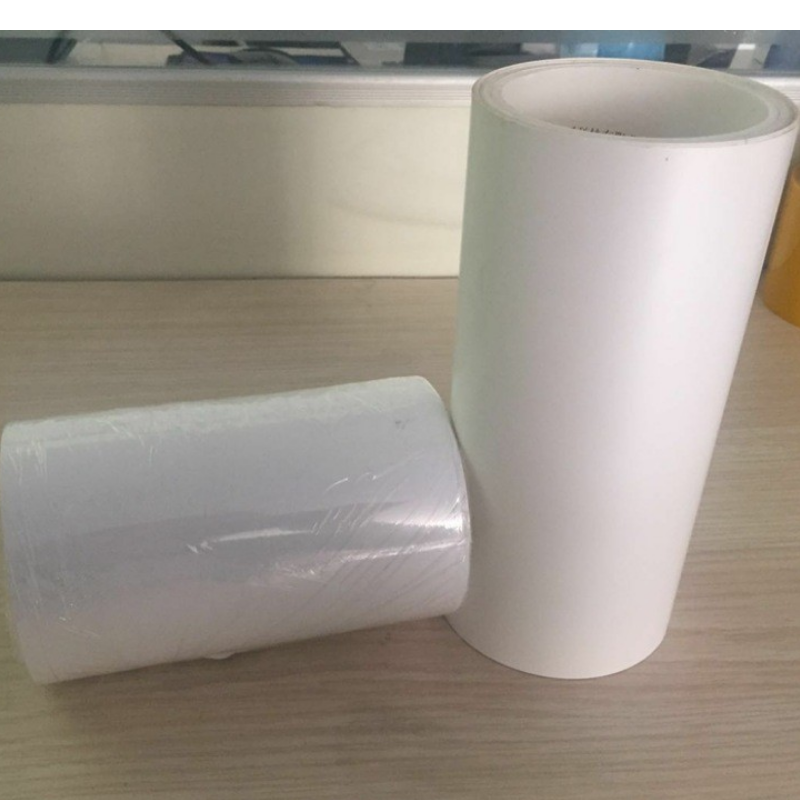

Eco-Friendly Rigid Pet Film Roll for Mirror and Decorative Material

1. Adhesion problem on the mold surface: During the PET blister process, adhesion may occur on the mold surface, causing the product to be unable to be demoulded smoothly. The solution is to apply a layer of anti-sticking agent on the surface of the mold to reduce the occurrence of adhesion.

2. PET sheet deformation problem: PET sheets are prone to deformation during the heating process, resulting in inaccurate product shapes. The solution is to control the heating temperature and time during the heating process to avoid deformation of the PET sheet caused by overheating.

3. Surface cracking problem of PET blister products: Surface cracking of PET blister products may occur during the cooling process, which affects the aesthetics and service life of the product. The solution is to control the cooling rate during the cooling process to avoid cracking due to large temperature differences caused by rapid cooling.

- Information

- Video

Product description

We produce PET raw materials - sheets or rolls, and also produce final products, PET cold drink cup lids, pastry boxes, bottom trays, etc. Welcome to consult

Common problems and solutions for PET sheet blister

1. Adhesion problem on the mold surface: During the PET blister process, adhesion may occur on the mold surface, causing the product to be unable to be demoulded smoothly. The solution is to apply a layer of anti-sticking agent on the surface of the mold to reduce the occurrence of adhesion.2. PET sheet deformation problem: PET sheets are prone to deformation during the heating process, resulting in inaccurate product shapes. The solution is to control the heating temperature and time during the heating process to avoid deformation of the PET sheet caused by overheating.

3. Surface cracking problem of PET blister products: Surface cracking of PET blister products may occur during the cooling process, which affects the aesthetics and service life of the product. The solution is to control the cooling rate during the cooling process to avoid cracking due to large temperature differences caused by rapid cooling.