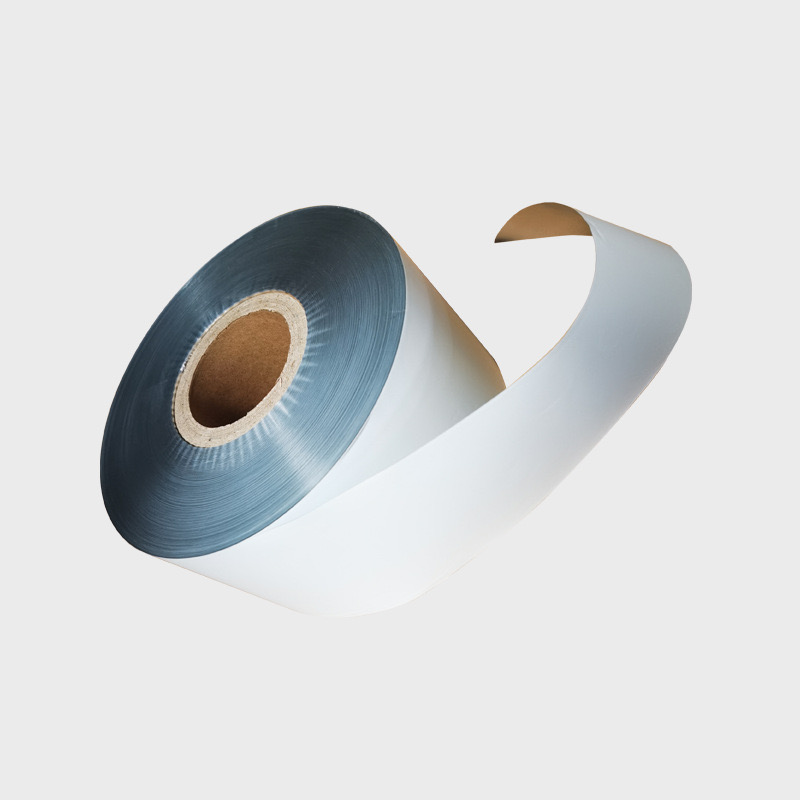

9 Layer PP Pa Pe Pvc Composite Film For Food Electronic

9 Layer PP Pa Pe Pvc Composite Film For Food Electronic

- top leader

- china

- 7 days

- 5000 tons per month

- Information

- Video

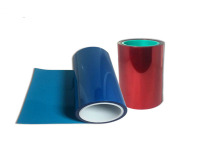

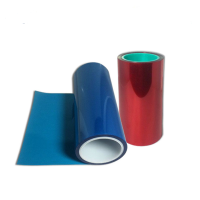

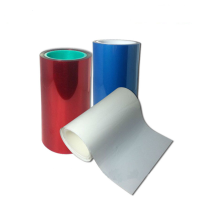

Product Description:

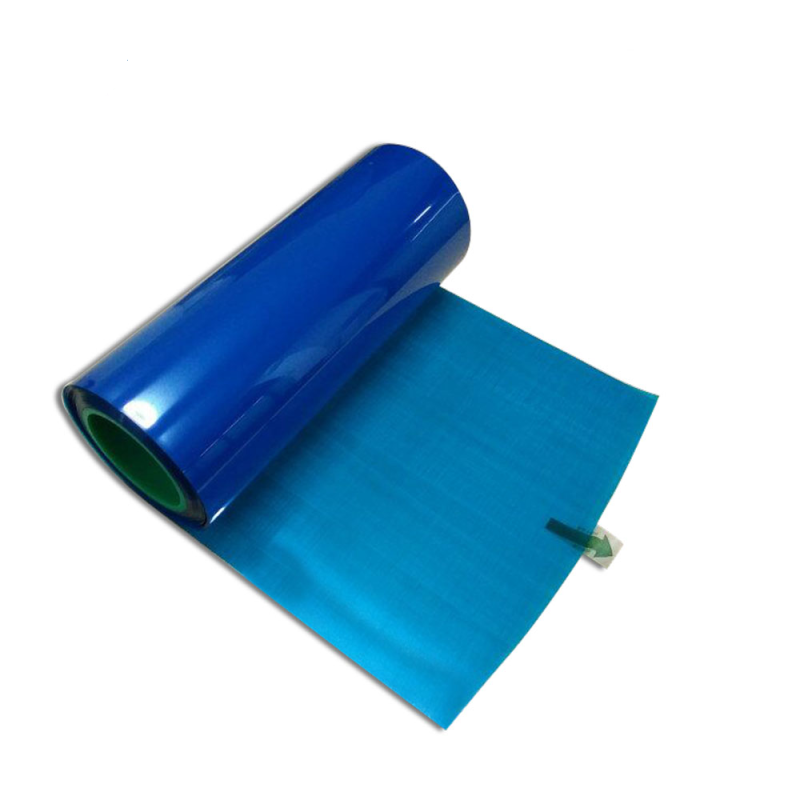

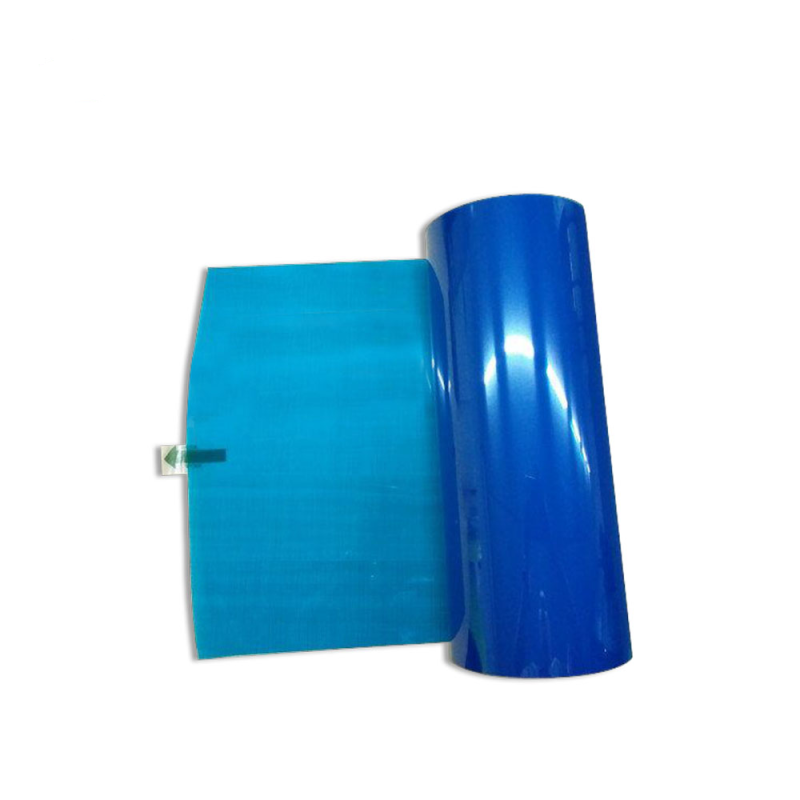

we can also provide matched top films/lidding films for rigid trays or flexible thermoforming packaging applications, with options including easy peel, color printing and barrier level. high and low temperature resistance,

0.06-0.09mm PA/PE co-extrusion printable anti-fog lidding film,

multi-layer top film with barrier,

OTR/WVTR barrier: EVOH high barrier or PA (medium barrier)

With High puncture and tear resistance.

for chilled pork and chicken.

| Name Component | 70-90 μm PA/PE | |||||

| Properties | Verify Mode | Unit | Value | |||

| Width | GB | mm | 424(±1) | |||

| Thickness | GB | μm | 90±10% | |||

| Weight | g/ | 87±10 | ||||

| Tear Strength | GB | KN/m | ≥40 (MD) | |||

| ≥40 (TD) | ||||||

| Breaking Elongation Rate | GB | % | ≥500(TD) | |||

| ≥500(TD) | ||||||

| Forming Temperature | ºC | 80-105 | ||||

| Sealing Temperature | ºC | 130-155 | ||||

| Forming Time | S | 1.8-3.0 | ||||

| Sealing Time | S | 1.3-3.0 | ||||

| Sealing Pressure | Mpa | 0.4-0.6 | ||||

| Sterilization | EO | |||||

| The data above are only for reference , not involve legal aspects. User has the | ||||||

| responsibility for confirming the range of applications.The material is national certified and belongs to non-toxic materials. | ||||||

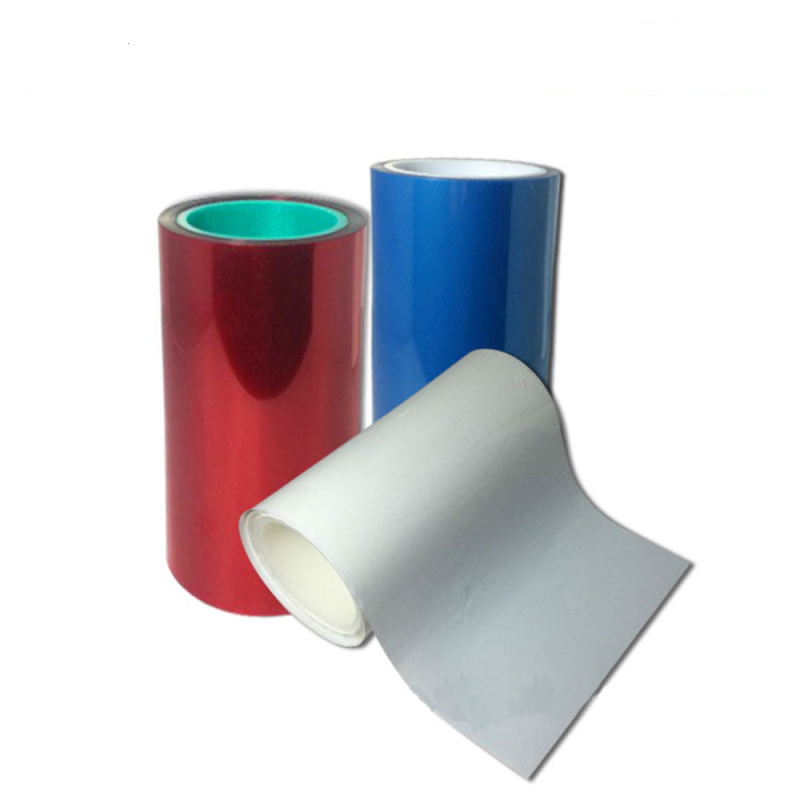

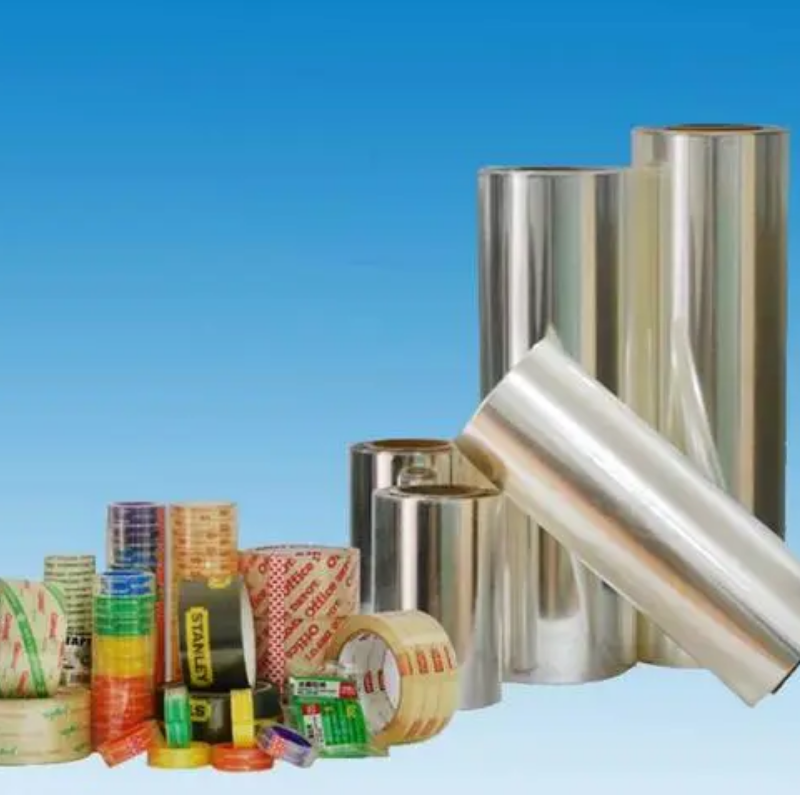

Main classification of blister products:

1, if according to the thickness of the material classification, can be divided into

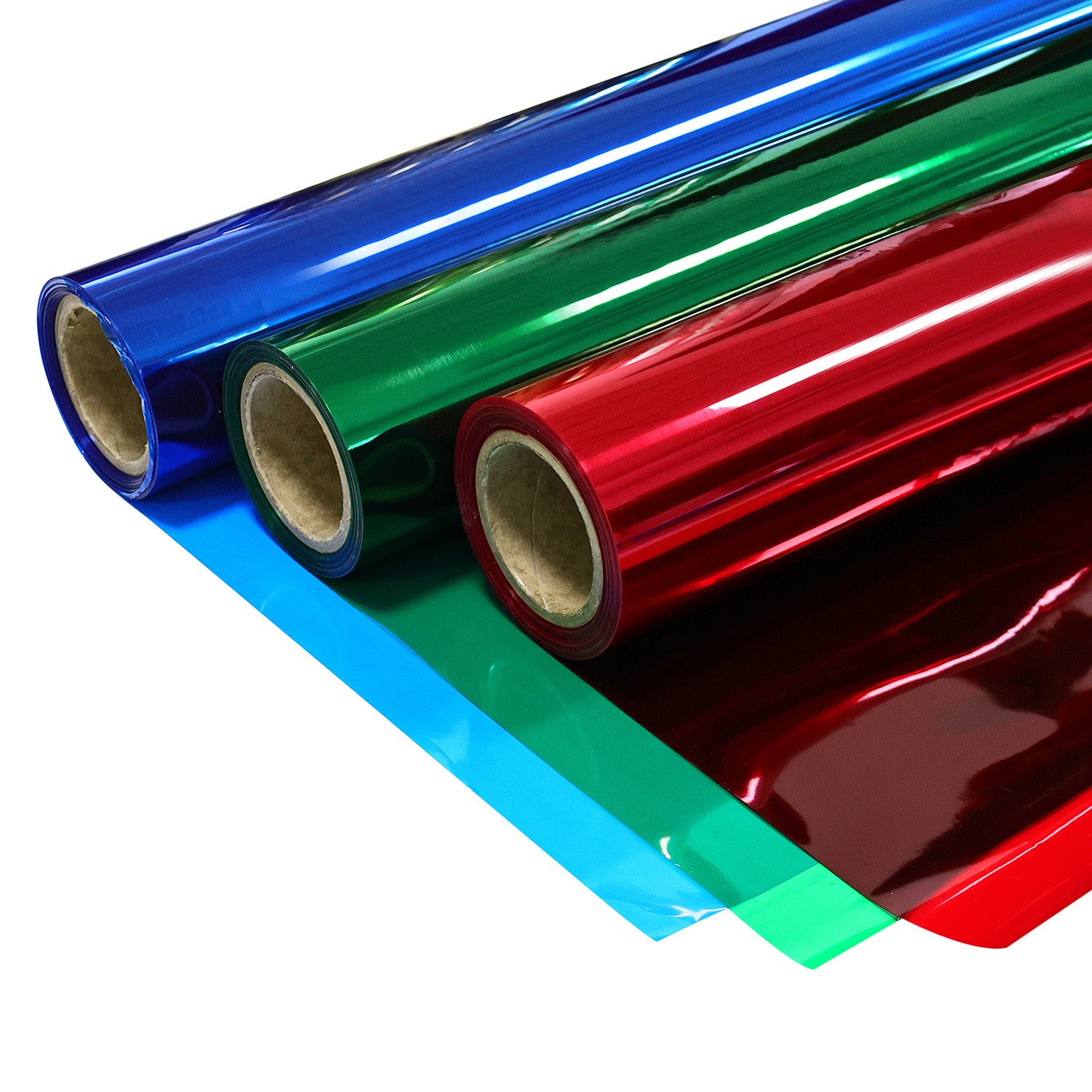

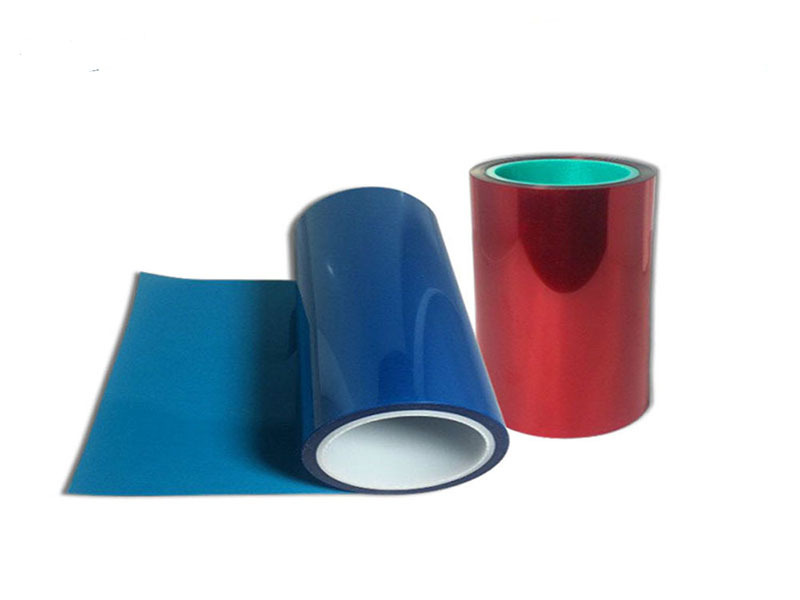

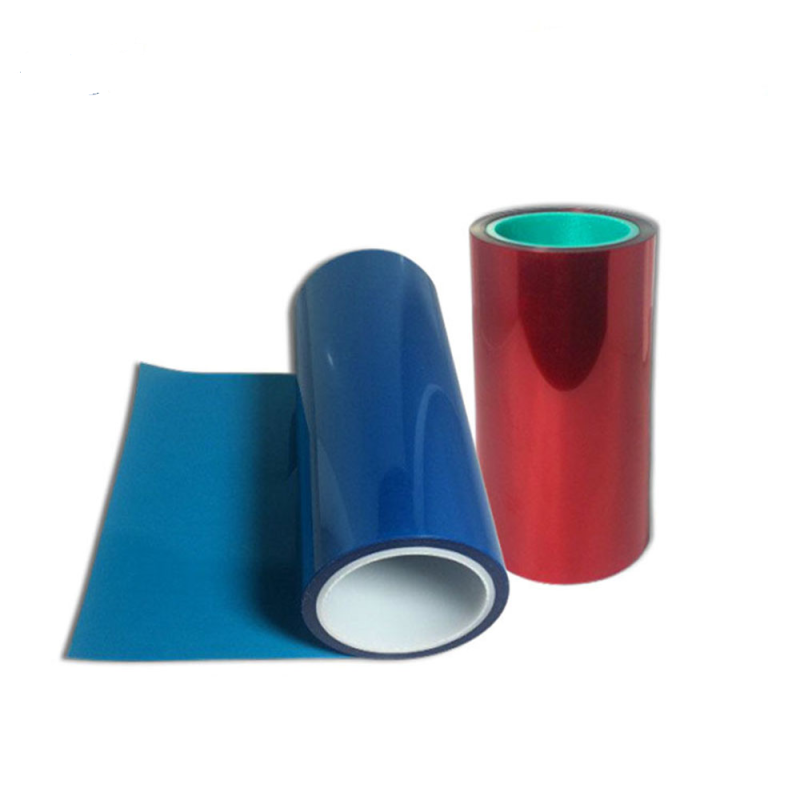

A, ordinary thin blister thickness of 0.14 ~ 5.0 mm - mainly use PVC, PP, PS (HIPS), PET (including APET, PETG), PE, BOPS, and recycled paper such as the effect of various materials and folding, folded in half, thirty percent, cylinder, folding box, box, high frequency and other non thermal forming blister products, widely used in food, medicine, electronics, toys, computers, daily necessities, cosmetics and mechanical hardware industry, etc.

B. Special thick blister thickness is 0.14 ~ 5.0mm -- mainly injection molding type blister products with PVC, PP, PS (HIPS, PET), ABS, PC, PE and other materials and effects.

The reason is not for the type of materials to be classified, mainly considering the ordinary thin blister and special thick blister used by the material there are some differences, but PVC, PP, PS and PET in the two types of blister products have a place!

PS hard sheet density is low, poor toughness, easy to burn, combustion will produce styrene gas (a harmful gas), so generally used to produce a variety of industrial plastic tray.

PET plate good toughness, high transparency, easy burning, burning does not produce harmful gases, belong to the environmental protection material, but the price is high, suitable for high-end blister products, blister blister of European and American countries generally require the use of PET plate, but it is not easy to heat sealing, bring great difficulty to the package, in order to solve this problem, people on the PET surface composite layer of PVC film, named PETG plate, but the price higher