TL-PE-700 PC plastic sheet led light diffuser film

PE membranes have become an integral part of combating static electricity in a host of industrial applications. These are able to block static electricity very effectively, and their durability as well as the fact that they are available at lower costs make them the ideal choice for a great number of industries in terms of process safety and efficiency. The role that PE membranes can achieve in blocking static with the continuous ongoing technology and material development is high, and the solutions are expected to be ever more robust for the control of static electricity.

- TOP LEADER

- CHINA

- 2 WEEKS

- 5000T/M

- Information

- Video

- Download

PE Membranes in Static Blocking Applications

Many related industries use polyethylene (PE) membranes with wide form of blocking, especially static. Static electricity is a cause of such observable complications as equipment damage, operational inefficiencies, and safety hazards—one of the very common phenomena connected with many industrial technological processes. The membranes in their PE version are designed with this in mind in order to effectively block static electricity from any level of process.

1. Understanding Static Electricity in Industrial Settings

Static electricity is brought about by an electric charge imbalance on, or within the surface of, a material. This can be a result in an industrial environment where such materials are being handled, transported, or packaged. Static accumulation can hold dust onto a material, result in static discharges, and under very severe conditions with flammable materials in the environment, even explosions.

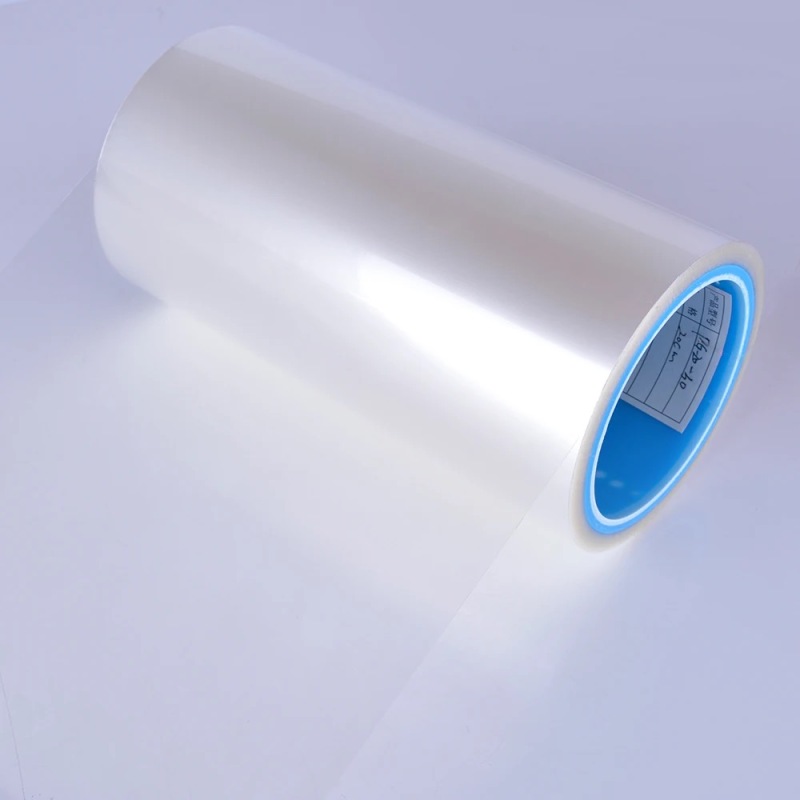

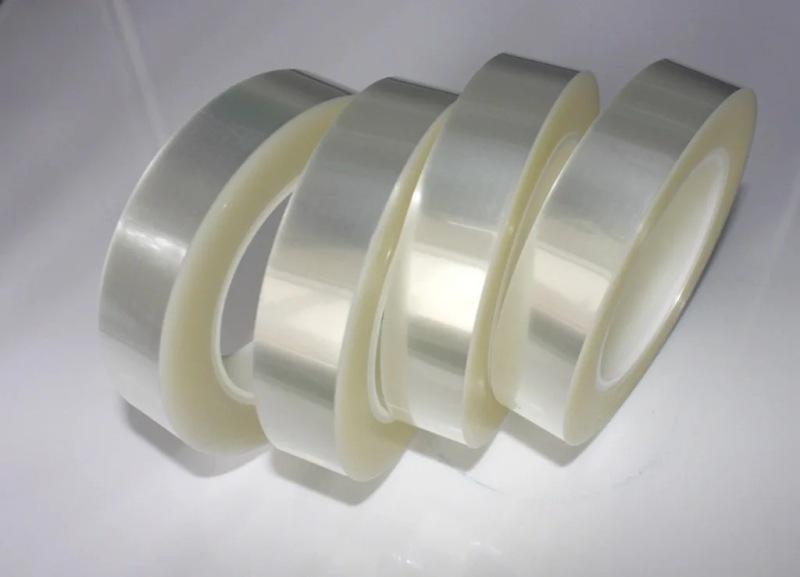

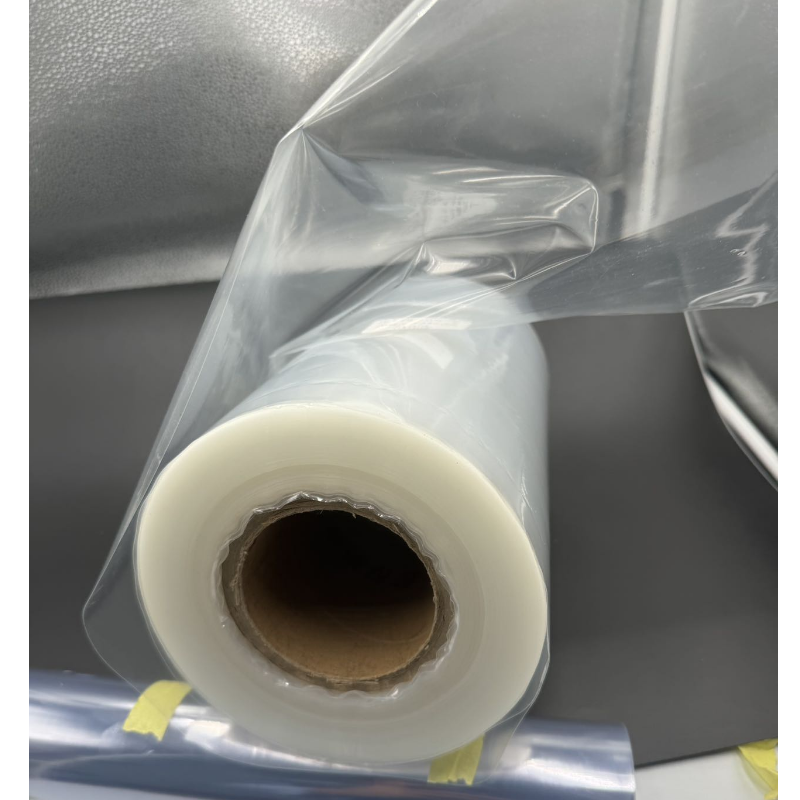

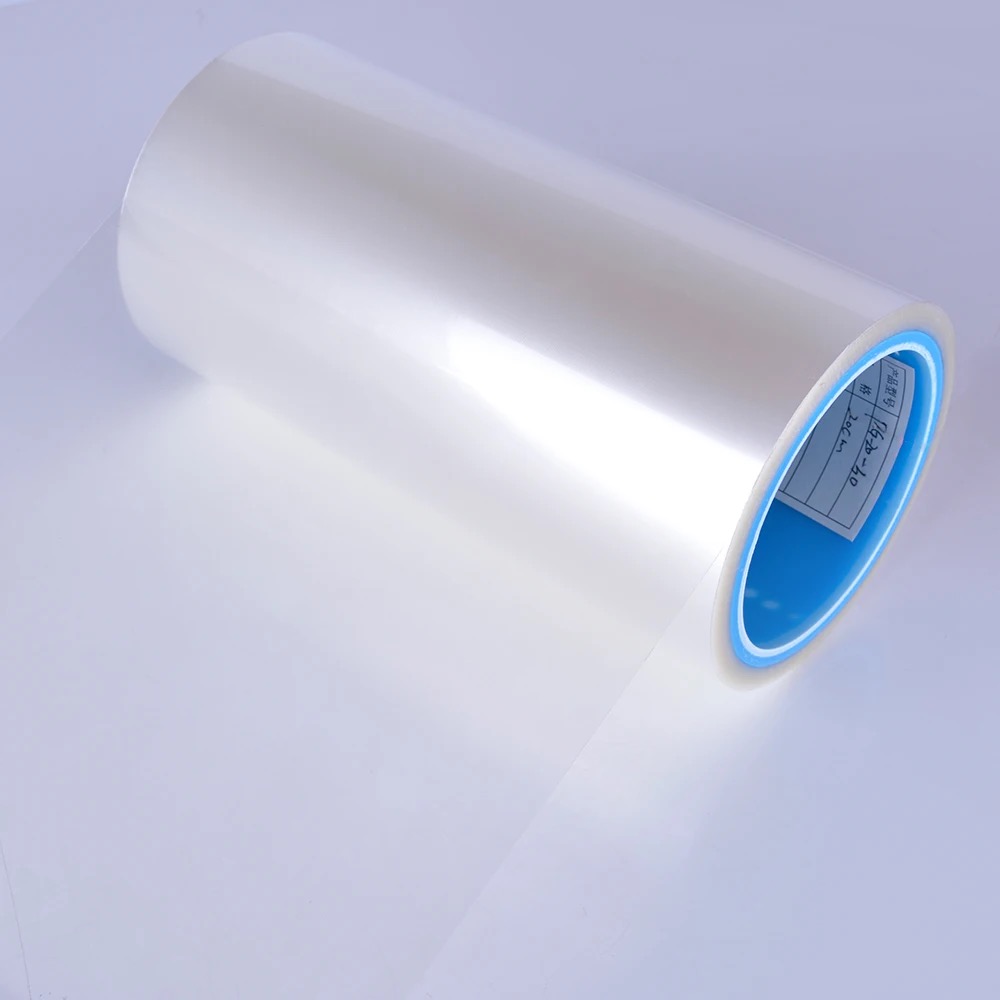

2. Introduction to PE Membranes

PE membranes are thin layers made up of polyethylene; this specific polymer is excellent in terms of flexibility and toughness. For the packaging of most plastics, PE is generally added to avoid the entry of moisture, chemicals, or any such thing into the packing. The membrane provides the controlling function for abrasion/static.

3. How PE Membranes Block Static Electricity

Static on the other hand is prevented by PE membranes through the same dielectric barrier. A dielectric is an insulator material where electric energy is stored by an electric field. Used as a membrane, polyethylene reduces the transfer of electric charges, hence the buildup of static on a given surface. This works on most parts where static-sensitive electronic items are to be held and on chances that static is a fire or explosion hazard.

4. Static Block Applications of PE Membranes

A large number of applications effectively uses PE membranes as a block to static electricity. Among those some of the prominent applications are:

- Manufacture of Electronics: Protecting sensitive parts from static discharge during manufacturing as well as in packaging is a major use of PE membranes in the electronics industry. These sensitive parts include microchips, circuit boards, and other electronic components that if exposed to static discharge may be damaged severely.

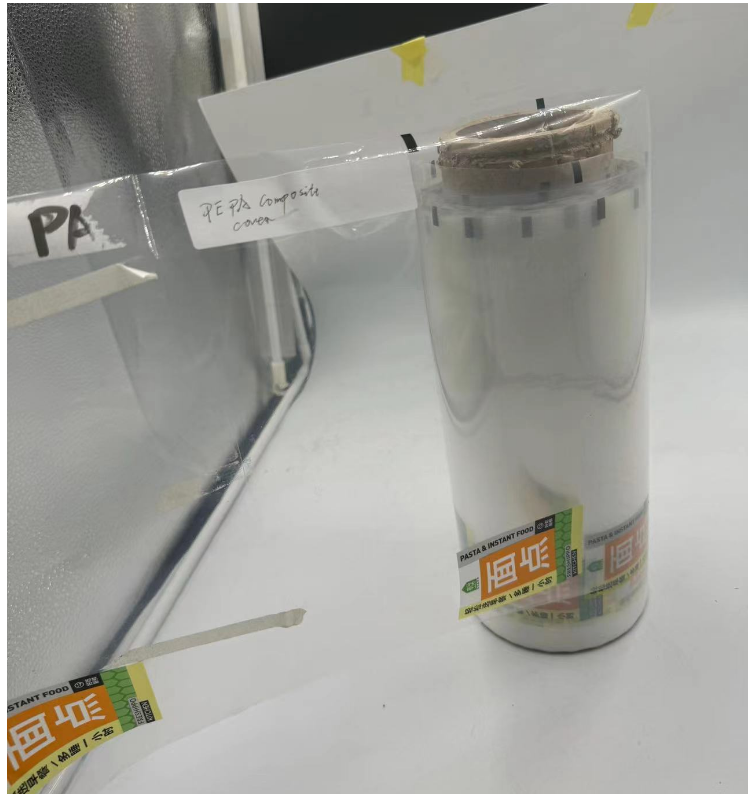

• Packaging: Another important use of static-blocking PE membranes is in the field of packaging products sensitive to static electricity. Such membranes do not allow the package and its contents to lose their integrity because of the effects of static electricity.

Industrial procedures: The PE membranes are also used within most of the industrial steps, including the lining of containers, conveyors, and other devices that are used in material transportation, among others. It reduces chances of static build-up and discharge leading to better and safer processes.

- Textile industry: In the textile industry, PE membranes are also employed to block the accumulation of static electricity in synthetic fabrics. The above can help in eliminating static cling and improving fabric comfort and durability.

5. Benefits of Using PE Membranes for Stopping Static

Some benefits are associated with using PE membranes for stopping static:

- Cost-Effective: It is much cheaper to produce PE than other membrane materials, therefore cost-effective and serves as the economic solution to static control in a wide range of applications.

- Durability: Polyethylene is a very strong material that can handle even the toughest of environmental conditions. This guarantees long-term performance in applications that stop static.

- Flexibility: PE membranes are flexible and assure easy applications in most industrial processes and products.

- Safety: Provides protection against explosion hazards that reduce the risks of a static discharge, especially in flammable material handling industries.

6. Conclusion

PE membranes have become an integral part of combating static electricity in a host of industrial applications. These are able to block static electricity very effectively, and their durability as well as the fact that they are available at lower costs make them the ideal choice for a great number of industries in terms of process safety and efficiency. The role that PE membranes can achieve in blocking static with the continuous ongoing technology and material development is high, and the solutions are expected to be ever more robust for the control of static electricity.