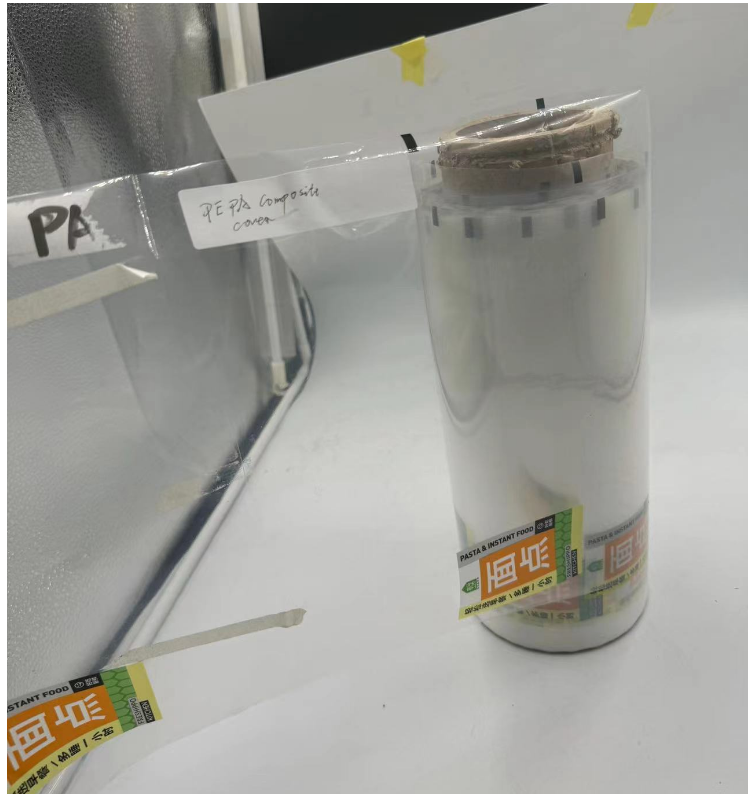

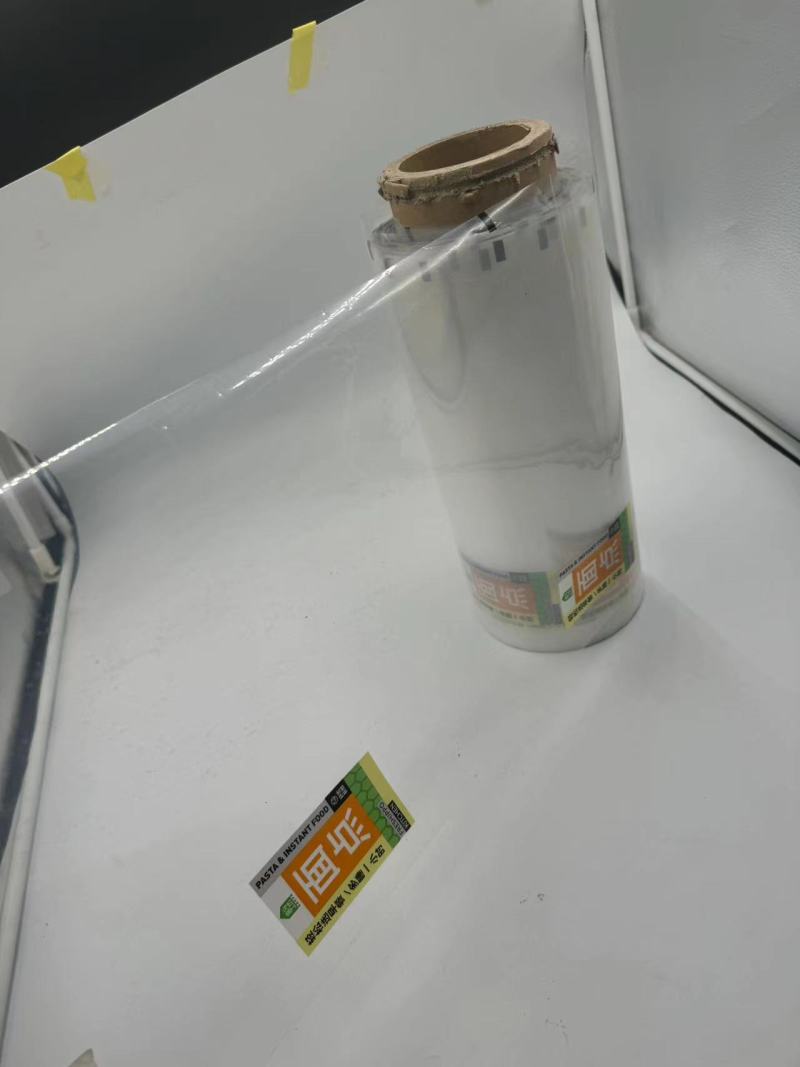

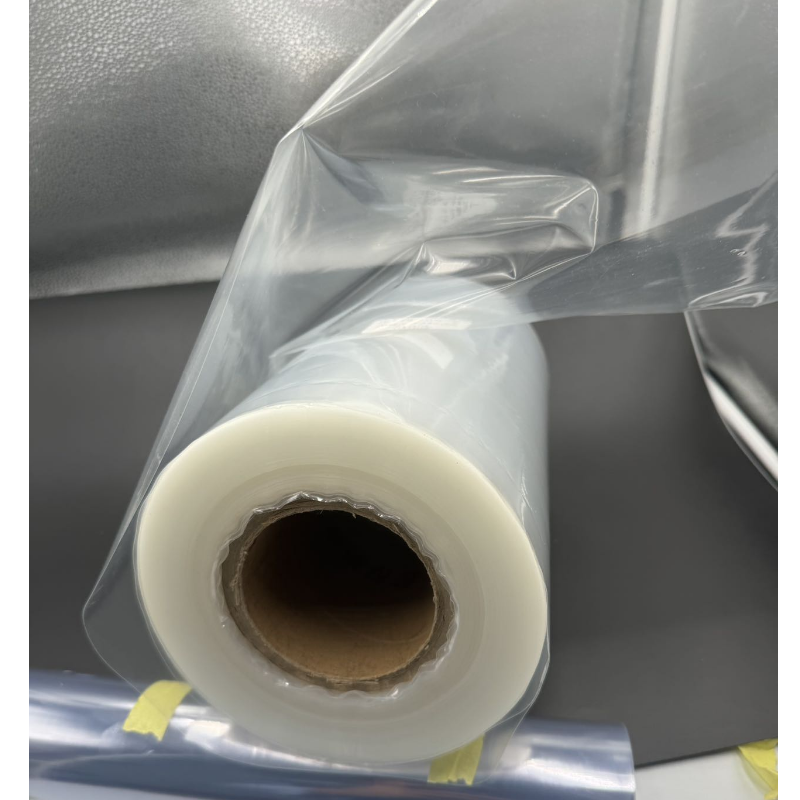

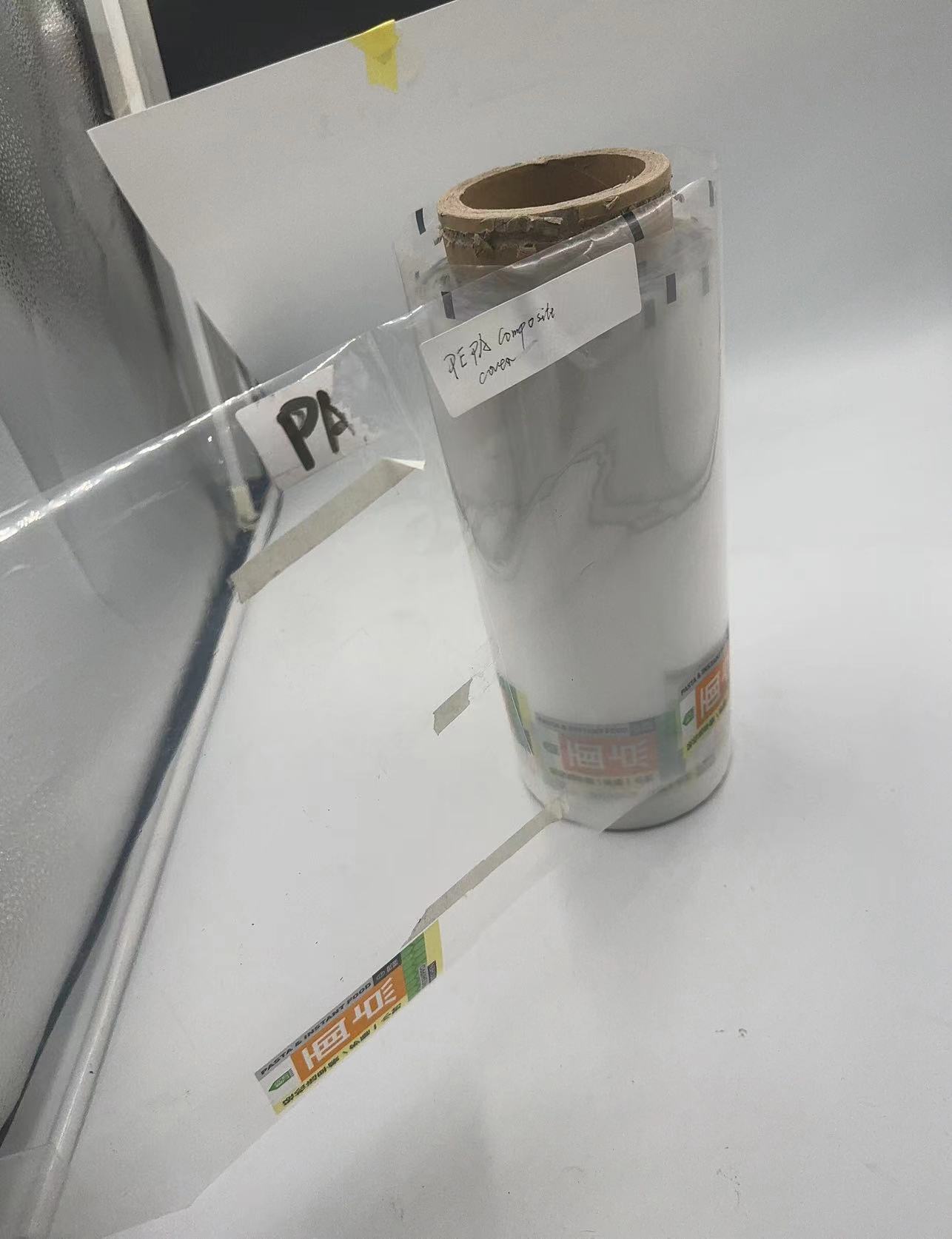

TL-PE/PE-601 Soft Transaprent PA/PE Heat-sealing Package Films

PE+PA composite films have very good heat sealability, thus enabling the production of tight and secure pouches. Heat sealing is a process whereby heat and pressure are applied at the edges of the film to form a strong hermetic seal. The important property here is in its extension of shelf life by preventing contamination and the loss of freshness for food products. This robust seal ensures that during transport and handling, the integrity of the packaging is maintained.

- TOPLEADER

- CHINA

- 15 WORKINGDAYS

- 5000T/M

- Information

- Video

- Download

That is why, owing to their outstanding properties, PE+PA composite films are gaining ever more uses in the food packaging industry. The combination of polyethylene's advantages with those of polyamide makes this film a versatile and high-performance solution in terms of packaging. Accordingly, the key advantages of PE+PA composite films will be examined hereafter in this paper, including non-toxicity, printability, color printing, machine recognition points, and heat sealability.

Of the many advantages, very important is the non-toxic properties of PE+PA composite film products. Such films are made with strict control over food safety, which means that they will not contain toxic components and will not exude dangerous components into the food goods. Hence, they will be safe to use with all kinds of foods, from snack foods to fresh produce, so that customers don't have to worry about their health.

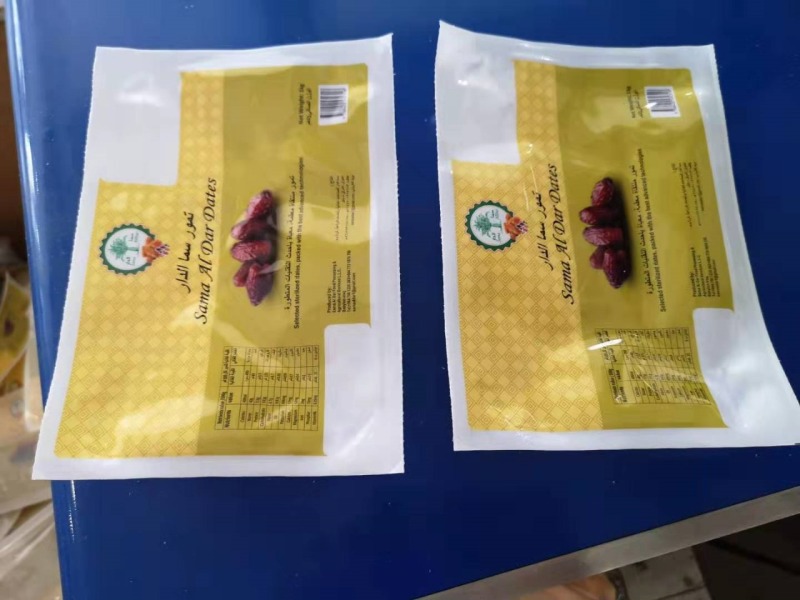

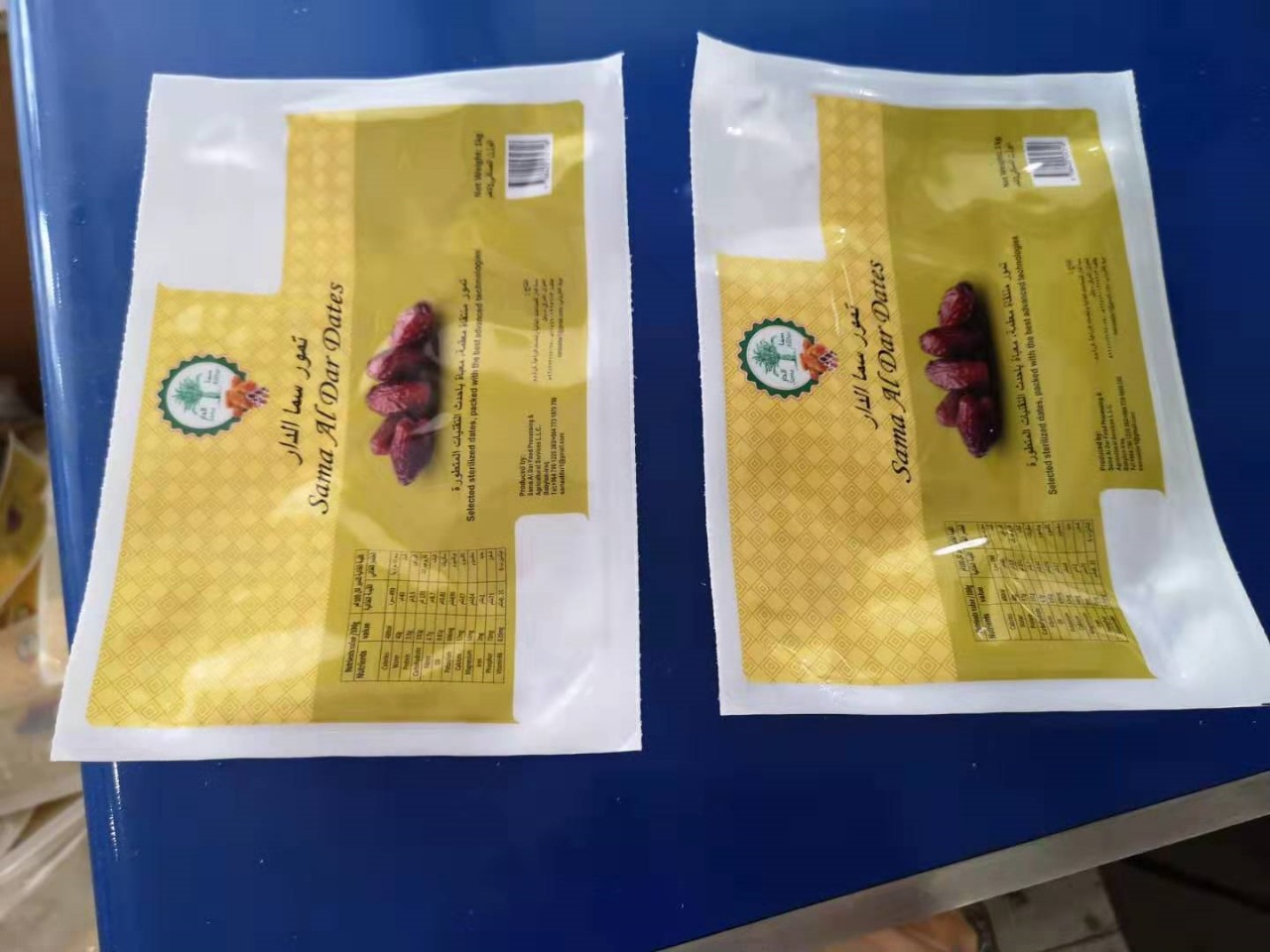

Printability and Color Printing

Printability: PE+PA composite films are excellent in printing, which is important in branding and marketing. The surface is designed to hold ink and dyes well, thus giving a clear view of graphics and text. Supports vivid color printing of packaging with catchy designs, informative features of the product, and promotional messages. Offers aesthetic appeal to food products at the shelf, and can give branding distinction amidst competition.

Thus, the incorporation of machine recognition points into the PE+PA composite film is such a technological advancement that facilitates efficient operations in terms of packaging. Such recognition points, in one way, allow automated systems to identify and line up the same with related packaging material during the production process. That means the precision of the overall packaging process increases and errors decrease, resulting in increased efficiency in the manufacturing environment.

Heat Sealability

PE+PA composite films have very good heat sealability, thus enabling the production of tight and secure pouches. Heat sealing is a process whereby heat and pressure are applied at the edges of the film to form a strong hermetic seal. The important property here is in its extension of shelf life by preventing contamination and the loss of freshness for food products. This robust seal ensures that during transport and handling, the integrity of the packaging is maintained.

Food Packaging Applications

The accruable benefits to PE+PA composite films move them toward applications in food packaging:

1. Snack Packaging: Non-toxic and with good sealing properties, they retain the crispness and flavor of snacks.

2. Fresh Produce: Printability/color capability creates attractive packaging for fruits/vegetables and allows heat sealability for freshness.

3. Ready-to-Eat Meals: The ability for heat sealing makes them quite suitable for the packaging of microwaveable and convenience foods. This ensures that the food inside remains well protected and fresh up until it hits the consumer.

4. Pharmaceuticals and Supplements: For food supplements and pharmaceutical products, their non-toxic and secure seal qualities mean product safety and efficiency.

Conclusion

Several other properties of the PE+PA composite films further improve their suitability as films for food packaging. Non-toxicity, printability, color printing, points for machine recognition, and heat sealability render the material quite versatile for addressing the requirements related to product safety, increasing shelf life, and improving the appearance of the packaging. Their adoption will likely increase with the evolving trend in food packaging since they meet modern packaging demands effectively.

Within 15-20 days after received payment...more